Hoisting erection system and erection control method for rocket launch platform at sea

A launch pad and rocket technology, which is applied in the direction of rocket launchers, offensive equipment, weapon types, etc., can solve the problem of failure to provide reverse thrust, affecting the safety of rockets and launch pads, damage to quiver assemblies or launch pads, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] First of all, it needs to be explained that the orientation words such as up, down, left, right, front, and back described in the present invention are only described according to the accompanying drawings, so as to facilitate understanding, and are not intended to limit the technical solution and scope of protection of the present invention. .

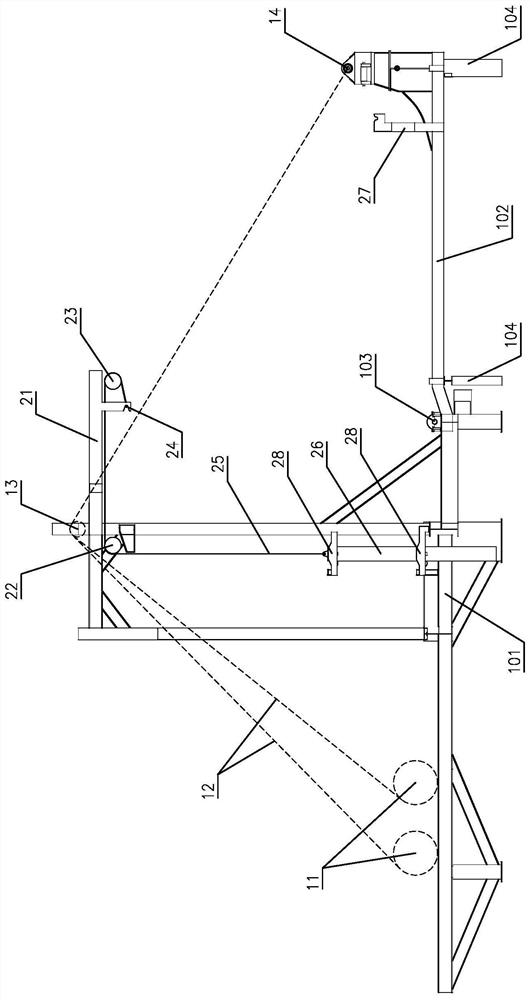

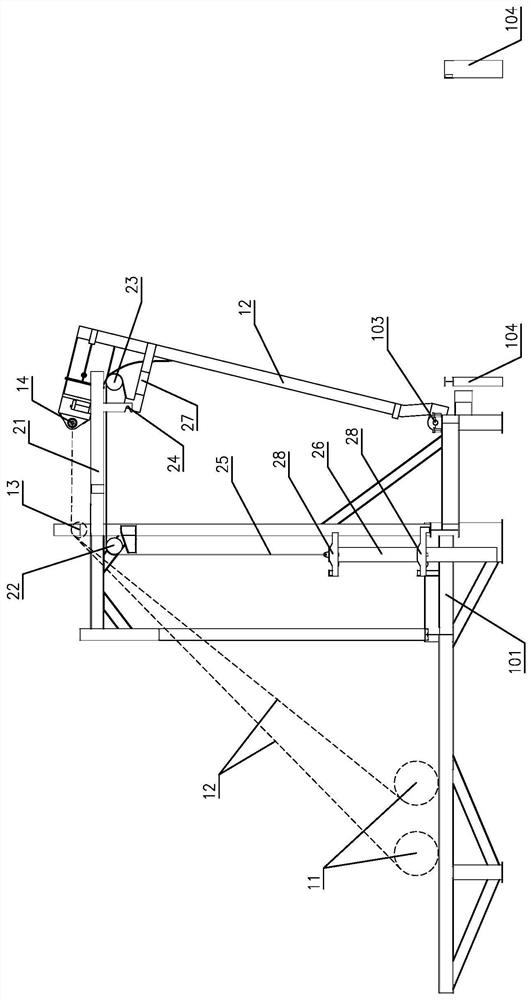

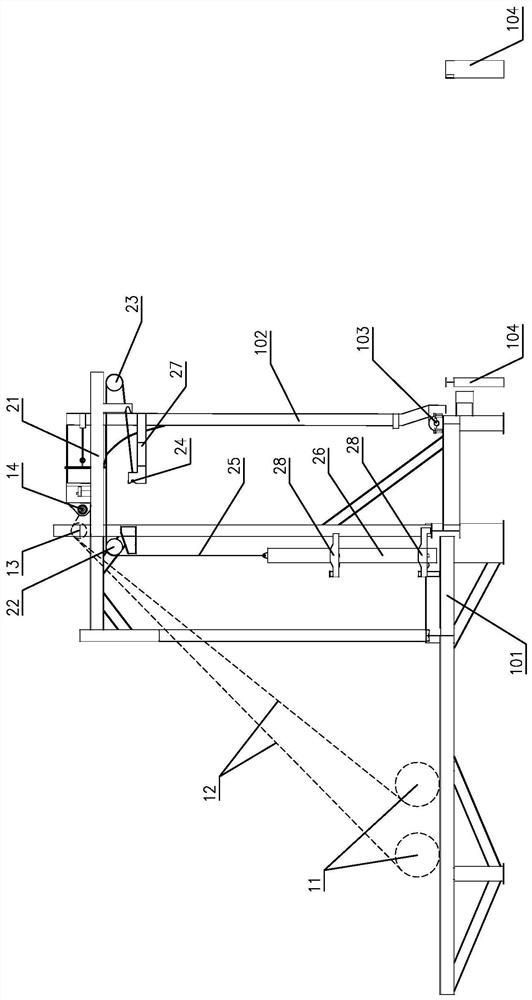

[0031] Such as Figure 1 to Figure 6 The specific implementation of the hoisting and erecting system for the rocket sea launch platform of the present invention is shown, including an erecting unit and a buffer unit. Make erecting unit to comprise hoist 11 and erect wire rope 12, hoist 11 is installed and fixed on the abutment left half of fixed frame 101, allow the left end of erect wire rope 12 to be fixedly connected with hoist 11, allow the right end of erect wire rope 12 to wind The erecting pulley 13 provided on the top of the fixed frame 101 is fixedly connected with the connecting ring 14 on the erecting frame 102 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com