ABS air processing unit dry efficiency testbed

An air handling unit and drying efficiency technology, applied in the field of test benches, can solve problems such as water circulation, and achieve the effects of strengthening the structural strength of the edge, simple and reliable splicing process, and easy penetration and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

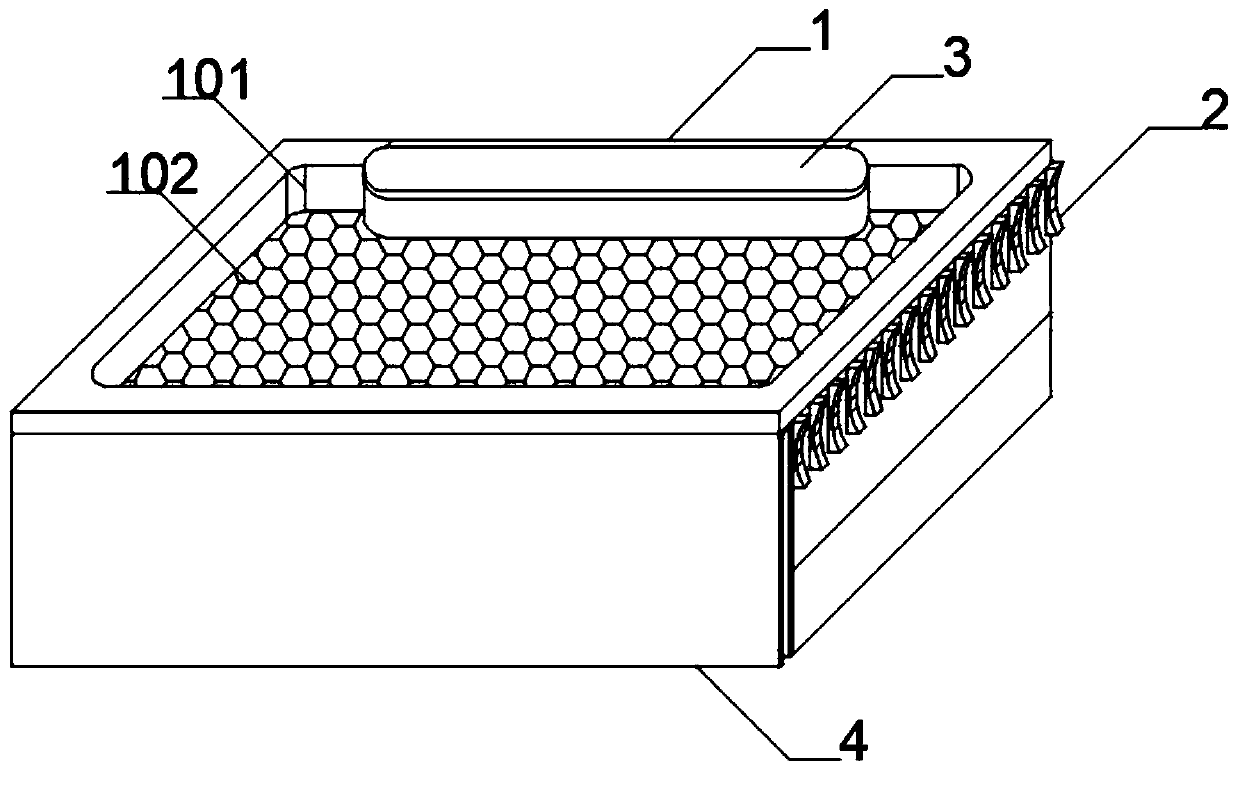

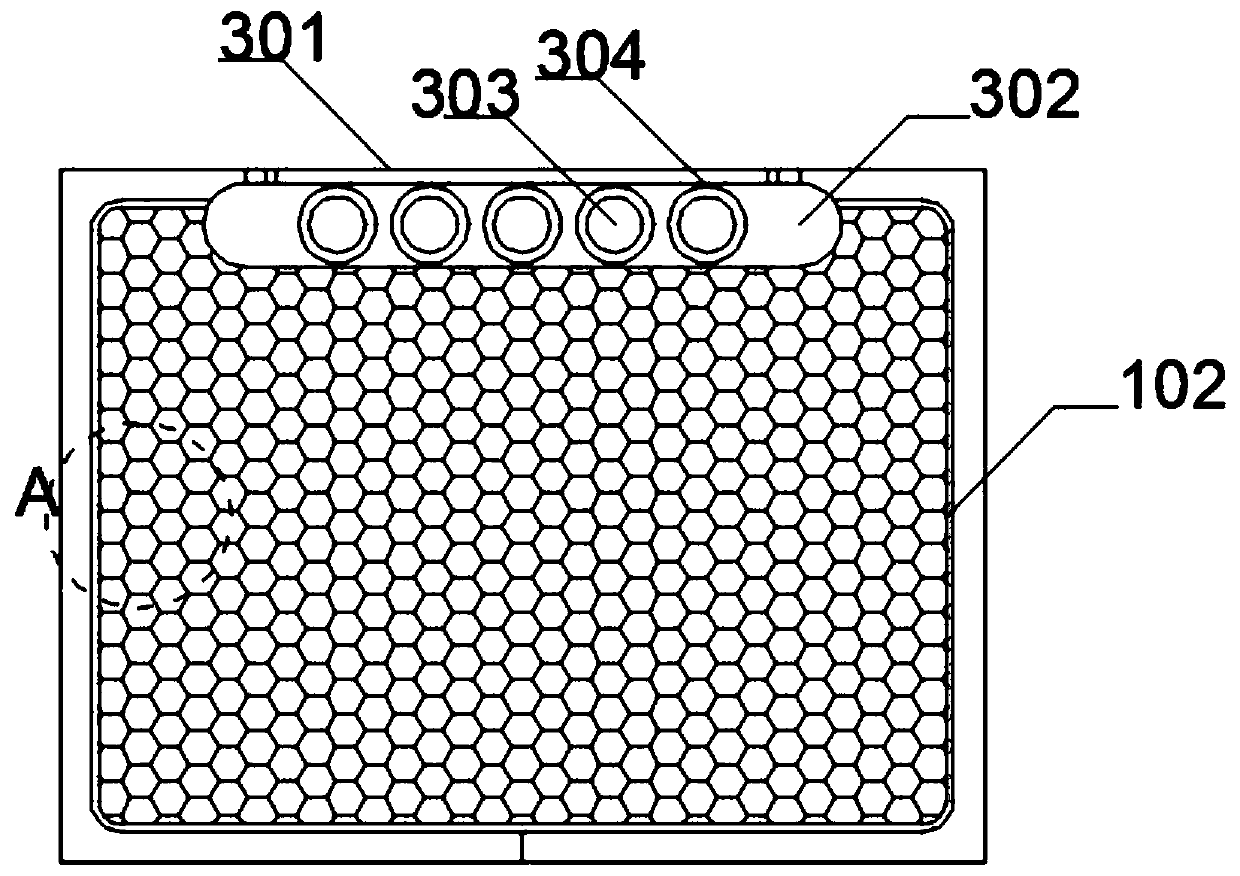

[0028] as attached figure 1 to attach Figure 4 Shown:

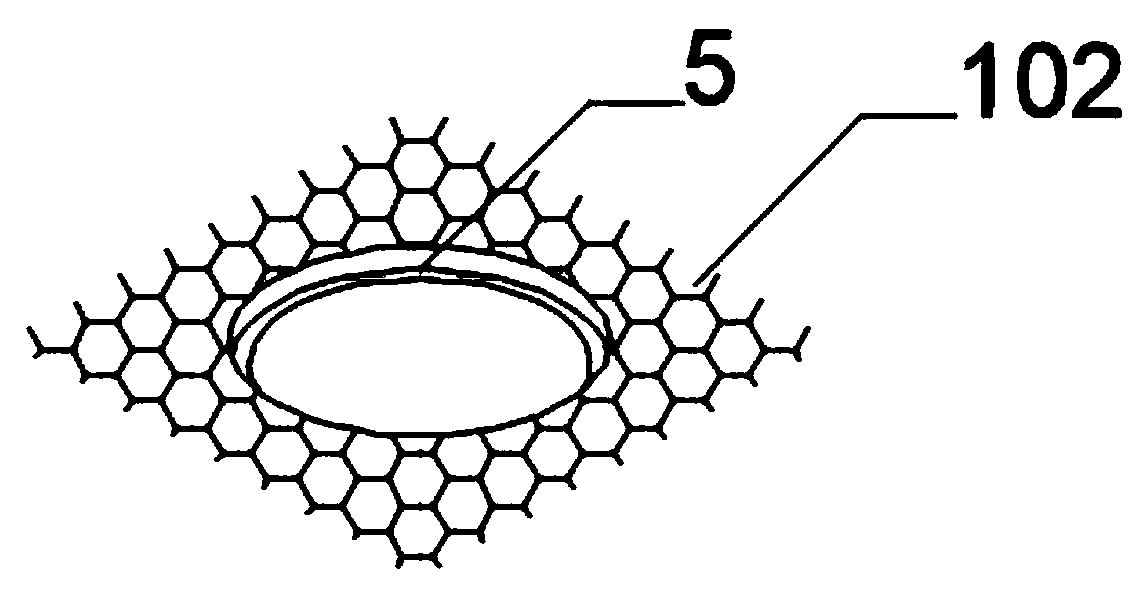

[0029] The invention provides a dry efficiency test bench for an ABS air processing unit, which includes an experimental table 1, side wing positioning piles 2, threading slots 3, embedded front foot panels 4 and integrated drainage and fixing grooves 5; the experimental table 1 The two sides of the panel are welded with side positioning piles 2 with metal raised structures; the top edge of the rear end of the test table 1 is equipped with threading slots 3 through the shaft structure; the front edge of the test table 1 is raised, and The bottom of the protruding part is inlaid with a front foot panel 4; the surface of the experimental table 1 is provided with a drainage and fixing integrated groove 5 inside.

[0030] Wherein, the experimental table 1 has a rectangular panel structure as a whole; the experimental table 1 includes an indentation groove 101 and a positioning grid 102; Groove 101; the inner surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com