Na < + > doped g-C3N4 composite material, electrochemical sensor as well as preparation method and application of same

A composite material, g-c3n4 technology, applied in the field of electrochemical sensors and its preparation, Na+ doped g-C3N4 composite materials, can solve the problems of inability to store charges on the hydrophobic surface and low surface utilization, and achieve high-efficiency electrochemical detection , Easy to operate, the effect of electrochemical signal enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 60mg of g-C 3 N 4 The powder was dispersed in 80 mL of deionized water, 15 mL of 4M NaOH solution was added dropwise thereto, and the resulting mixture was kept stirring at room temperature for 24 h. After the reaction, wash with deionized water and collect Na + doped g-C 3 N 4 product, and finally put the product into an electric blast drying oven to dry to obtain Na + doped g-C 3 N 4 Powder, recorded as NC-15.

Embodiment 2

[0029] Weigh 60mg of g-C 3 N 4 The powder was dispersed in 80 mL of deionized water, then 20 mL of 4M NaOH solution was added dropwise thereto, and the resulting mixture was placed at room temperature and stirred continuously for 24 h. After the reaction, wash with deionized water and collect Na + doped g-C 3 N 4 product, and finally put the product into an electric blast drying oven to dry to obtain Na + doped g-C 3 N 4 Powder, recorded as NC-20.

Embodiment 3

[0031]Weigh 60mg of g-C 3 N 4 The powder was dispersed in 80 mL of deionized water, and then 25 mL of 4M NaOH solution was added dropwise thereto, and the resulting mixture was placed at room temperature and stirred continuously for 24 h. After the reaction, wash with deionized water and collect Na + doped g-C 3 N 4 product, and finally put the product into an electric blast drying oven to dry to obtain Na + doped g-C 3 N 4 Powder, recorded as NC-25.

[0032] Na + doped g-C 3 N 4 Performance Testing:

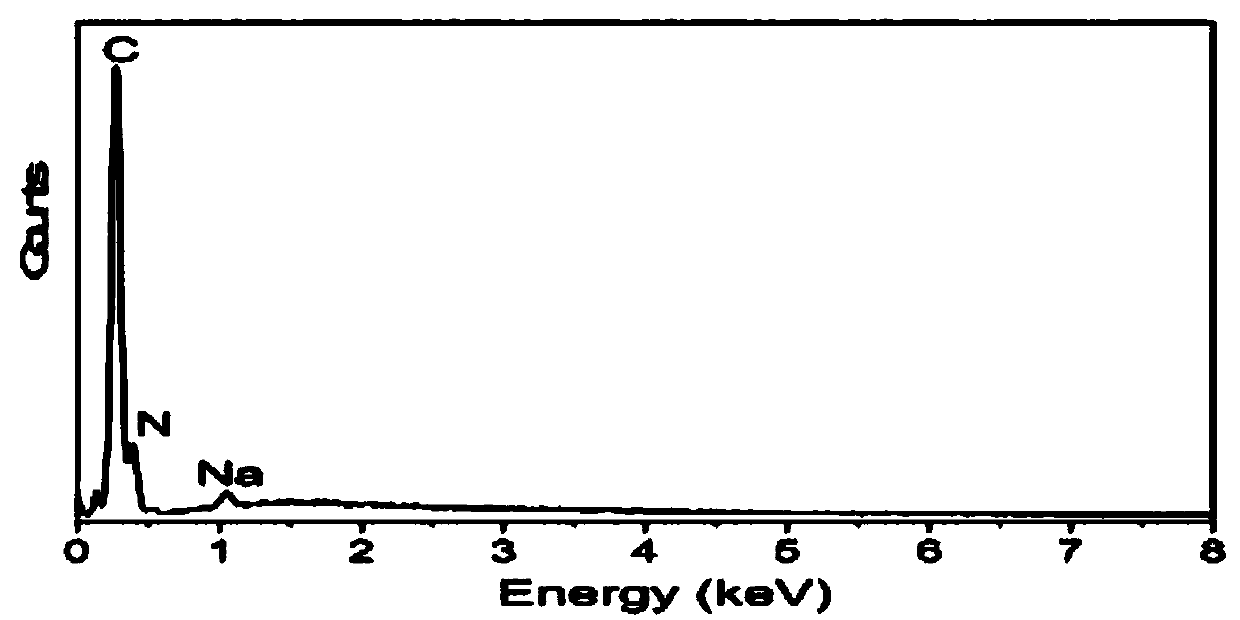

[0033] 1. Analysis of Na + doped g-C 3 N 4 Morphological characteristics of composite materials:

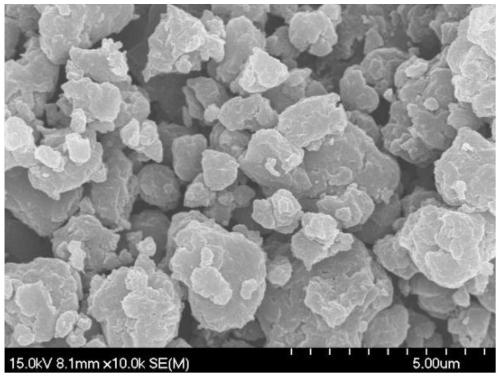

[0034] figure 1 for Na + doped g-C 3 N 4 Scanning transmission electron microscope (SEM) image; From the morphology and structure of SEM, it can be clearly seen that Na + doped g-C 3 N 4 The powder presents an irregular massive structure, about 2–6 μm.

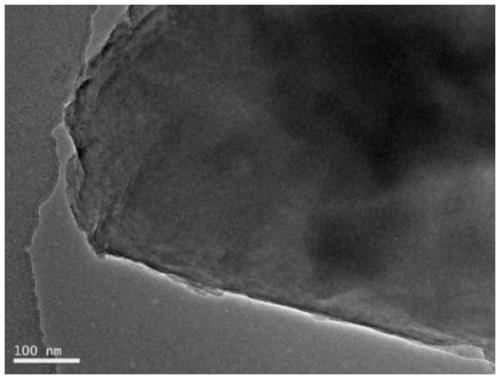

[0035] figure 2 for Na + doped g-C 3 N 4 The transmission electron microscope (TEM) picture; It can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com