Anti-rotation and play-proof crimp sleeve assembly and connector using the same

A technology of crimping sleeves and connectors, which is applied in the direction of electrical components, etc., can solve the problems of poor anti-rotation and anti-movement effects of cables, reduced rigidity of the installation panel, and limited sealing of the installation hole, so as to avoid rigidity The effect of greatly weakening, simple and reliable assembly, and enhanced sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

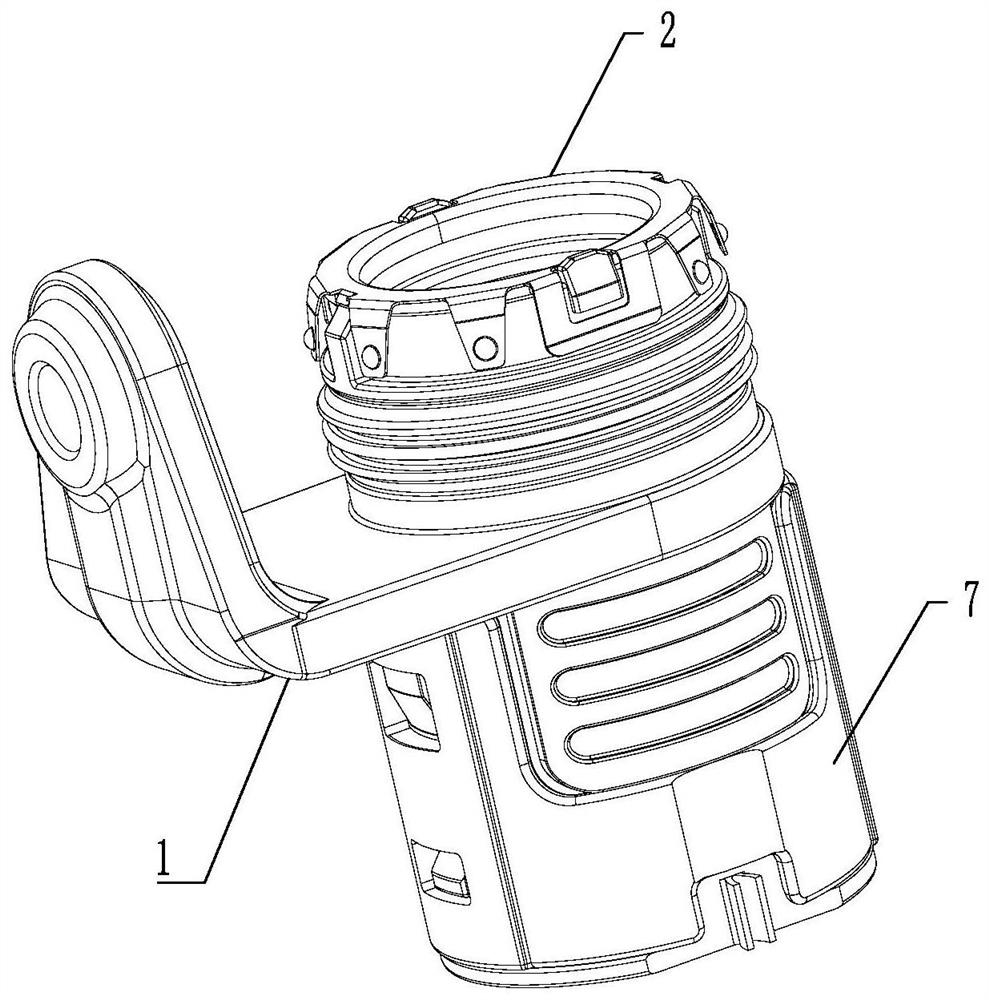

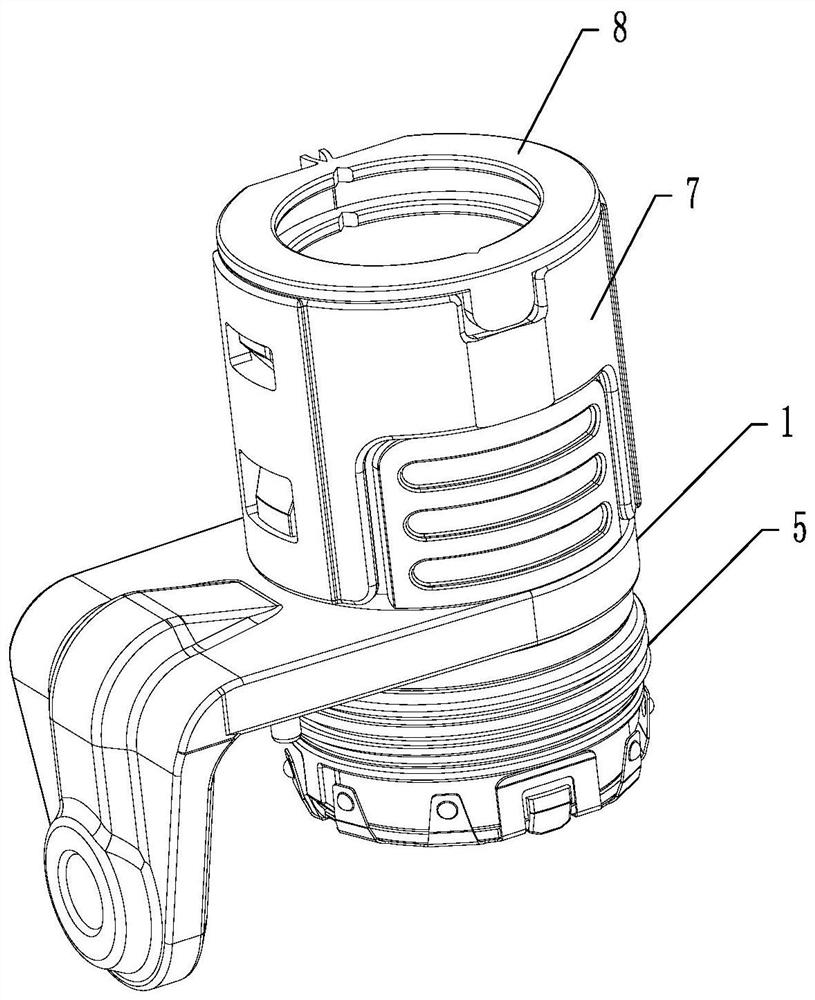

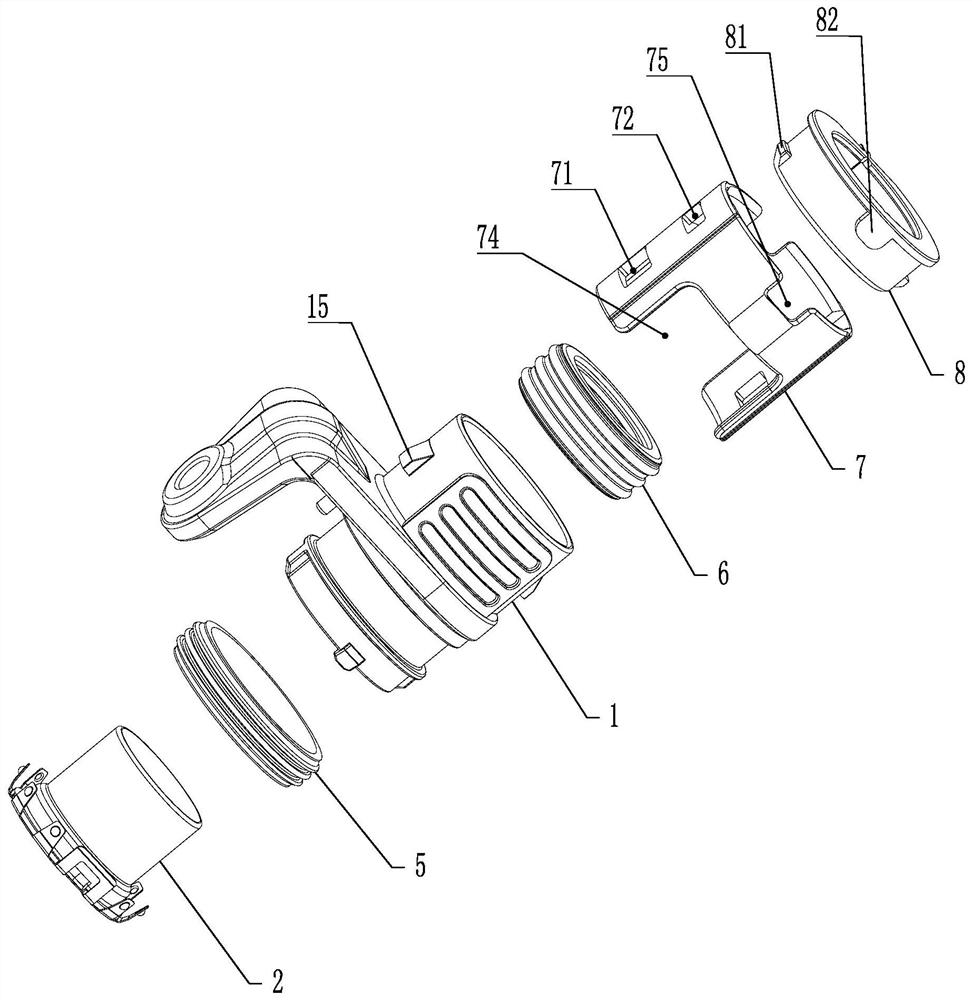

[0031] The specific embodiment of the connector proposed by the present invention, such as Figure 1 to Figure 8 As shown, it includes a metal shell 1. A threading hole perpendicular to the installation panel is opened in the metal shell 1. A crimping sleeve assembly 2 is axially installed in the threading hole. The crimping barrel 3 in contact with the cable shielding layer can ensure the pull-off force and contact reliability with the cable after crimping; the front end of the crimping barrel 3 is welded with a shrapnel 4 through spot welding, and the end face 41 That is, the end face perpendicular to the axis of the crimping barrel) is folded toward the rear end of the crimping barrel 3 so as to form a plurality of elastic arms 42 that elastically press against the inner wall of the straight hole on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com