3D printing individual rib replacement prosthesis and preparation method thereof

A 3D printing and prosthesis technology, applied in the field of bone repair, can solve the problems of bone wear, pain, and different lengths, and achieve good biocompatibility, non-displacement, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

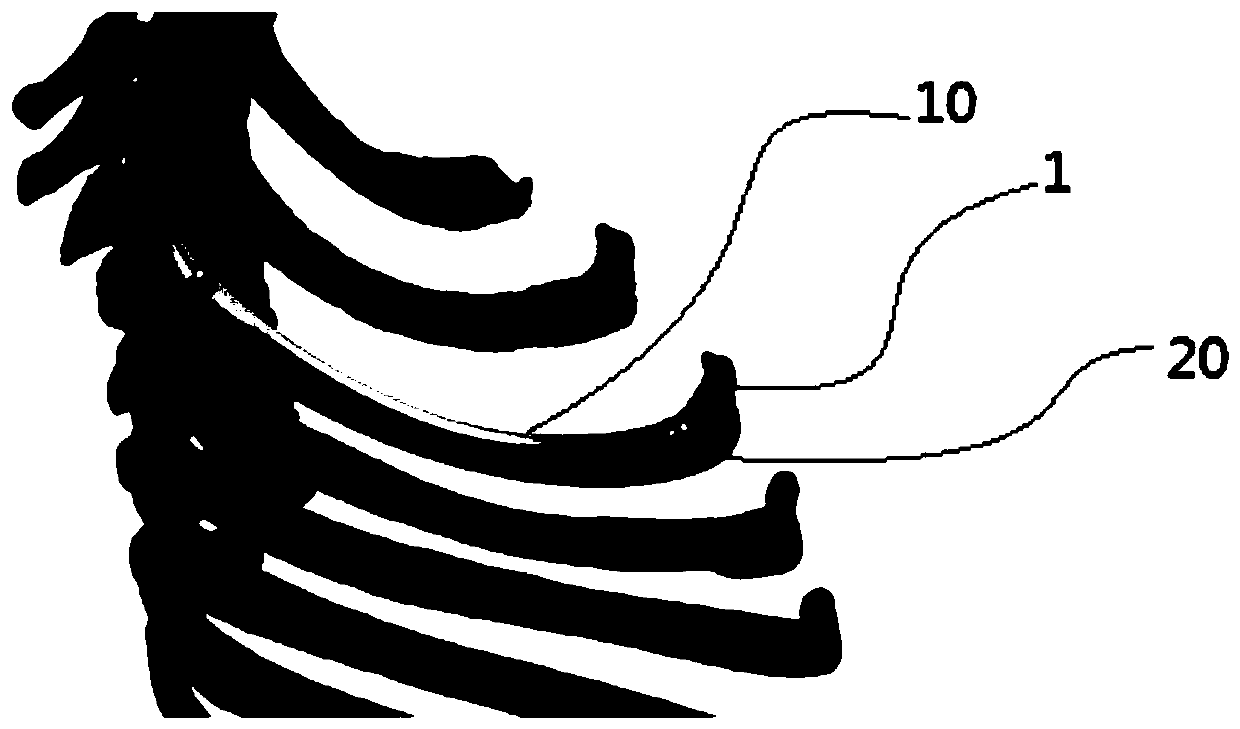

[0030] The "residual bone" mentioned in this article refers to the two remaining bone sections after surgical resection, and the missing part is between the two remaining bone sections, and the missing part is replaced and reconstructed with artificial prosthesis. During reconstruction, the two ends of the artificial prosthesis are respectively docked with the two fractures of the residual bone.

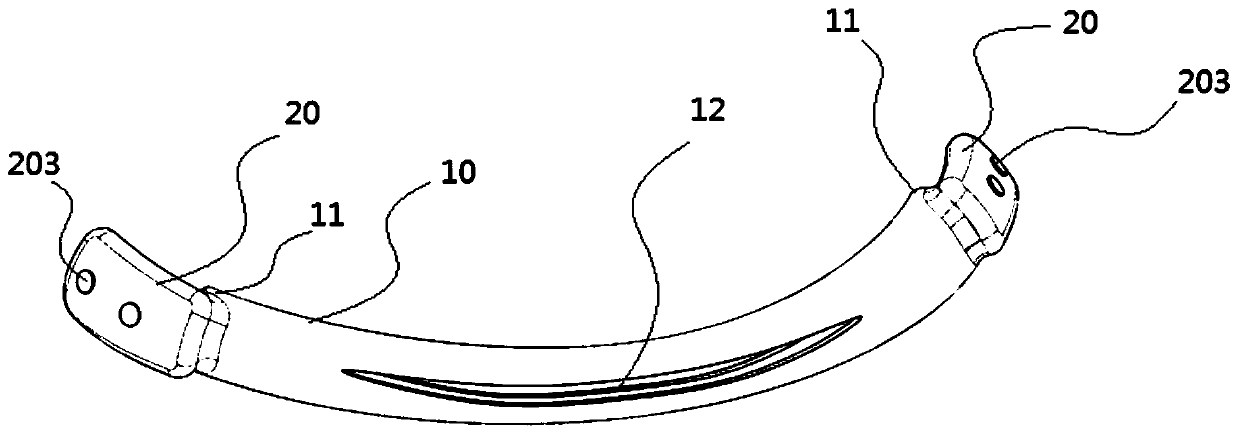

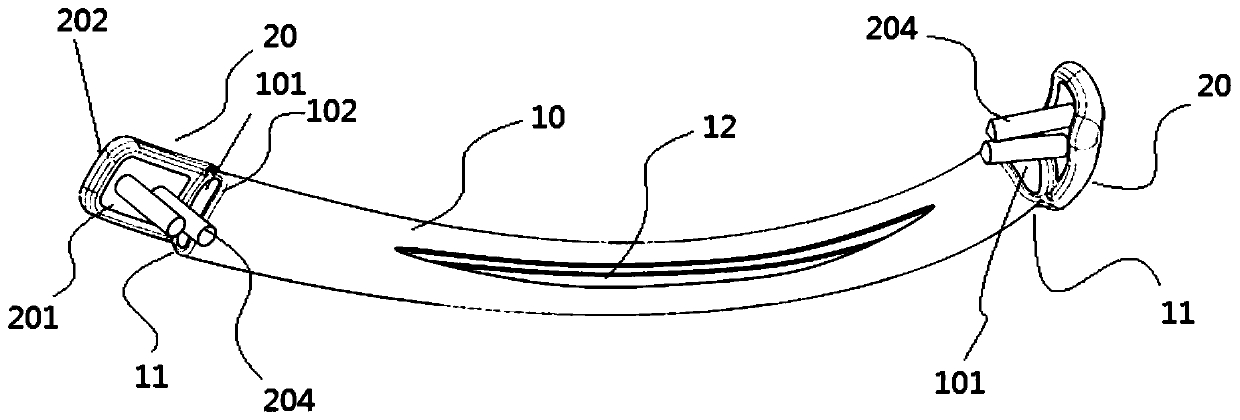

[0031] Such as figure 1 , 2 As shown, it is a 3D printed personalized rib replacement prosthesis of the present invention, including:

[0032] The prosthesis body 10, which completely imitates the shape of the ribs to be replaced; the prosthesis body 10 has two ports 11, and the two ports 11 are respectively matched and docked with the fractures of the two residual bones to be reconstructed; and

[0033] The connectors 20 respectively arranged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com