Powdered material blanking device

A technology of powder and material bags, which is applied in the field of powder material unloading device, can solve the problems of time-consuming and manpower, dust explosion, low production efficiency, etc., and achieve the goal of reducing manpower waste, reducing direct injuries and avoiding the risk of cuts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

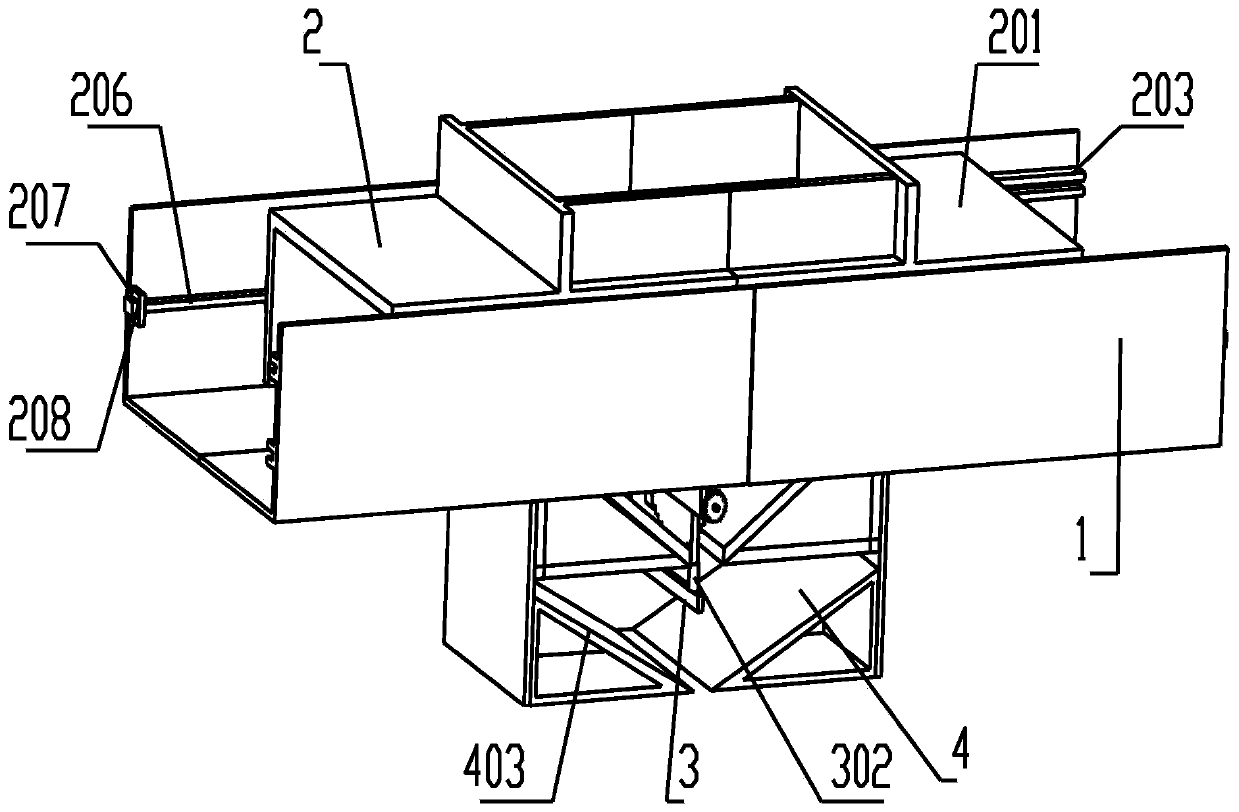

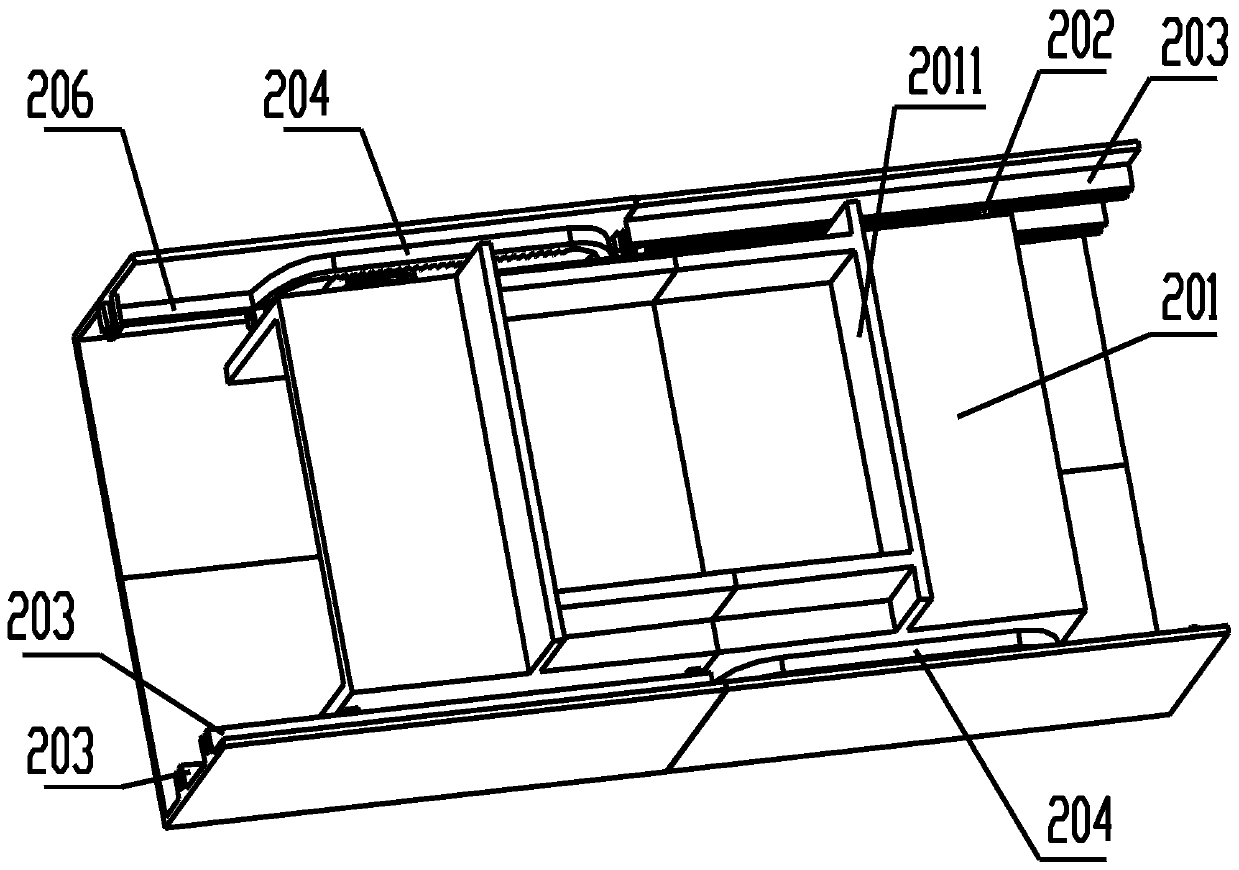

[0033] see Figure 1 to Figure 6 , the present invention provides a kind of powdery material unloading device, comprises frame 1, two movable desks 2 are arranged symmetrically on frame 1, and the lower middle part of frame 1 is provided with material passing mechanism 4, and the middle and upper part of material passing mechanism 4 Setting the cutting mechanism 3;

[0034] The mobile desk 2 includes two symmetrical brackets 201, each of which is driven by a drive mechanism to move horizontally; The block 202 is provided with a slideway 203; the bracket 201 is slidably connected with the frame 1; two sets of sliders 202 and slideways 203 are arranged side by side on the side wall of the bracket 201 up and down.

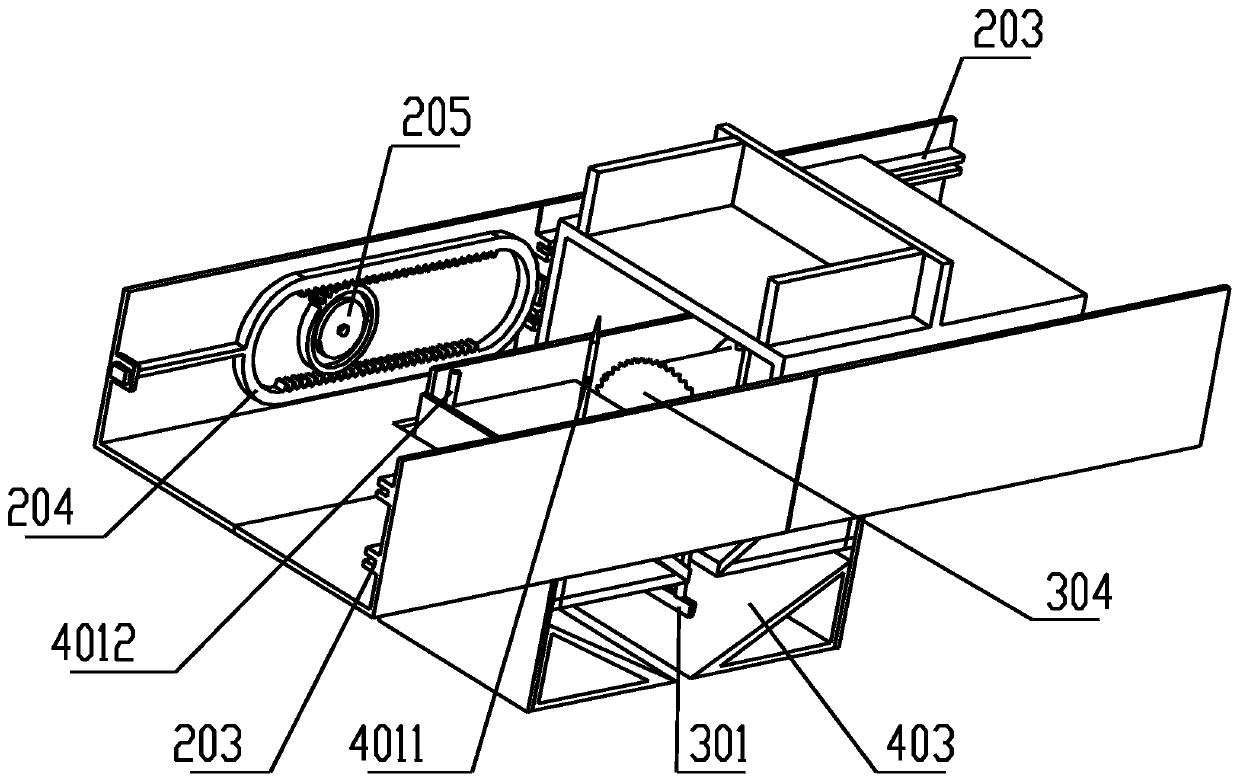

[0035] Cutting mechanism 3 comprises the cutting support frame 301 that is fixed on the material passing mechanism 4 housings, and cutting support frame 301 is provided with two elevating rods 302, and elevating rod 302 is provided with the second support platform 30...

Embodiment 2

[0054] On the basis of Embodiment 1, when the two mobile tables 2 move backwards, the material bag falls down, and first touches the material bag tie bar 4011, the material bag tie bar 4011 is tied into the material bag, and then the bag corner tie bar 4012 Tie into the four corners of the material bag, and the material bag is fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com