A method for cutting and reusing TPT sheets for damaged photovoltaic panels

A photovoltaic panel, broken technology, applied in the direction of laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems such as complex structure, and achieve the effect of simple structure, resource saving and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

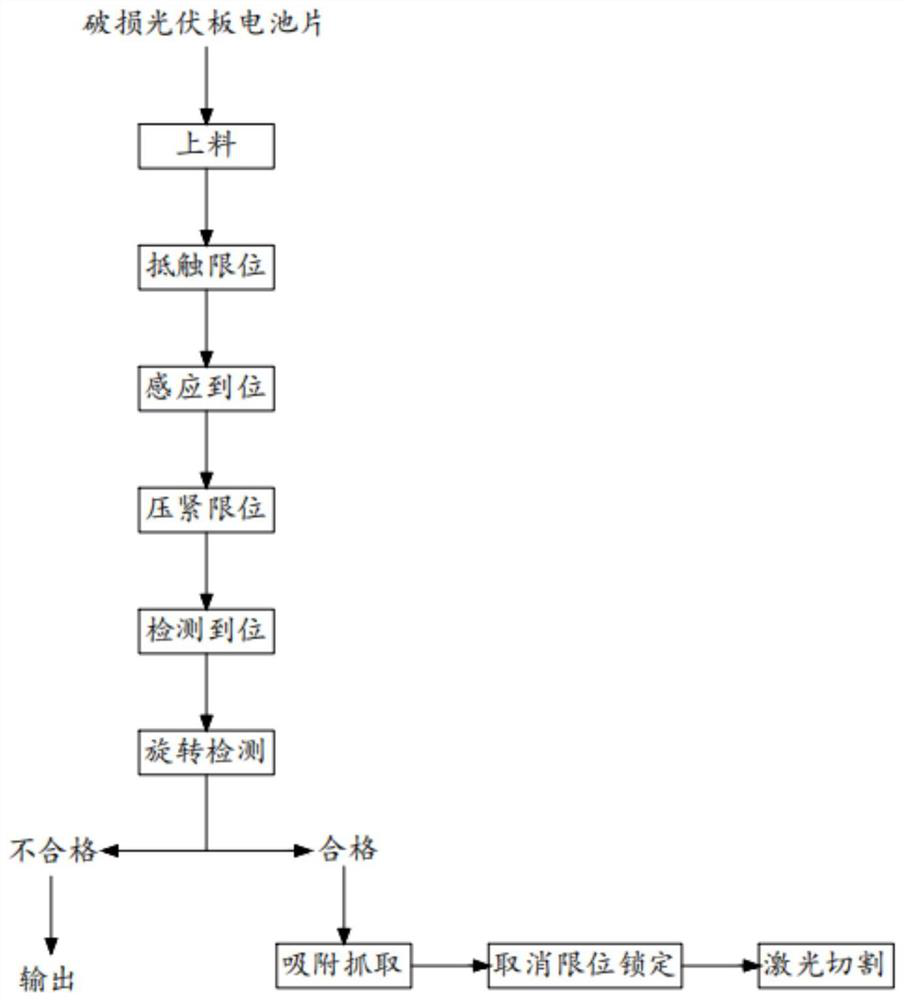

[0054] A method for cutting and reusing damaged TPT sheets for photovoltaic power generation system production, characterized in that it comprises the following steps:

[0055] Step 1, feeding, place the damaged TPT sheet 21 horizontally on the workbench 2, the workbench 2 is rotatably mounted on the frame 1, and the frame around the workbench 2 is provided with a sliding device around the workbench 2. The interference component 31, the four corners of the TPT sheet 21 and the corresponding interference component 31 are arranged facing each other;

[0056] Step 2, the collision limit, the horizontal push drive members 44 symmetrically arranged on both sides of the workbench 2 push to the TPT sheet 21, and the elastic adjustment assembly 34 synchronously drives the interference assembly 31 located at the four corners of the TPT sheet 21 Sliding engagement on the corresponding included angle of the TPT sheet 21, and the horizontal push drive member 44 pushes the corresponding el...

Embodiment 2

[0078] Referring to Example 1, a system for cutting and reusing damaged TPT sheets for photovoltaic power generation system production according to Example 2 of the present invention will be described.

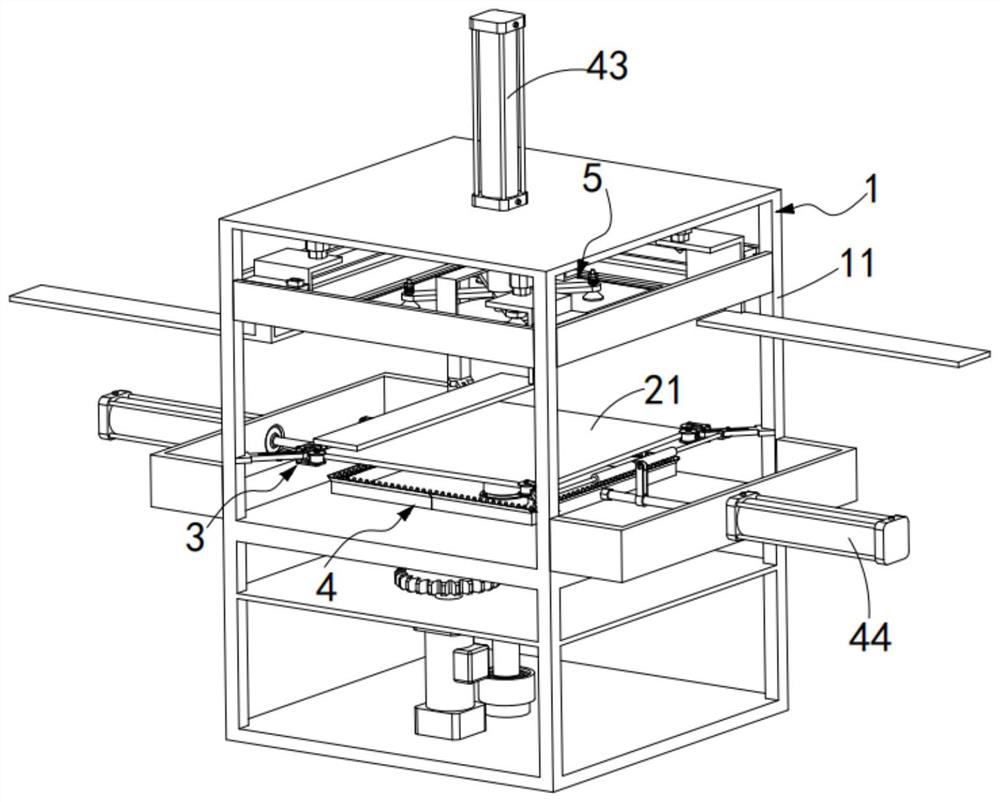

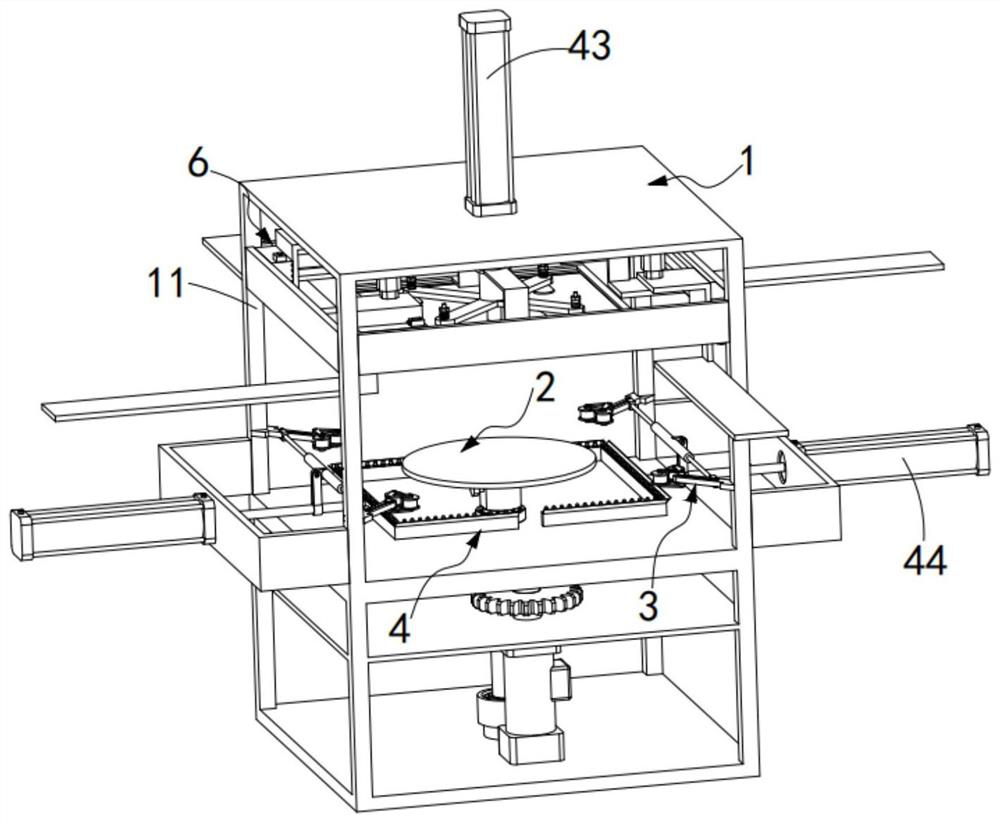

[0079] Such as Figure 2 to Figure 8 As shown, a system for cutting and reusing damaged TPT sheets for photovoltaic power generation system production includes a frame 1 set in a frame, and also includes:

[0080] A workbench 2, the workbench 2 is rotatably arranged on the frame 1, and the TPT sheet 21 is horizontally placed on the workbench 2;

[0081] The positioning mechanism 3, the positioning mechanism 3 is symmetrically arranged at the four corners of the workbench 2, and it is arranged to elastically interfere with the four corners of the TPT sheet 21 placed on the workbench 2, and it is arranged with the TPT sheet 21 The collision component 31 of the collision part can be rotatably set;

[0082] The detection mechanism 4, the detection mechanism 4 includes a detectio...

Embodiment approach

[0110] Such as Figure 14 and Figure 15 As shown, as a preferred implementation manner, the induction component 42 includes:

[0111] U-shaped frame 421, the U-shaped frame 421 is symmetrically arranged, and it is connected with the pushing end of the corresponding horizontal pushing driver 44;

[0112] Photoreceptors 422, several of the photoreceptors 422 are arranged equidistantly along the U-shaped setting path of the U-shaped frame 421; and

[0113] The light guide sheet 423, the light guide sheet 423 is arranged on the outside of the light sensor 422 along the U-shaped installation path of the U-shaped frame 421, and the light guide sheet 423 is arranged obliquely and flared upward.

[0114] It should be noted that, if the damaged TPT sheet 21 meets the requirements for cutting and reuse, after being rotated, the damaged part will be rotated out of the light coverage range, and the damaged TPT sheet 21 will block the light emitted by the light source part 412 from bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com