Damaged TPT sheet cutting and reutilizing system for photovoltaic power generation system production

A photovoltaic power generation system and reuse technology, applied in welding/cutting auxiliary equipment, laser welding equipment, auxiliary devices, etc., can solve problems such as complex structure, and achieve the effect of rapid detection and identification, simple structure and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

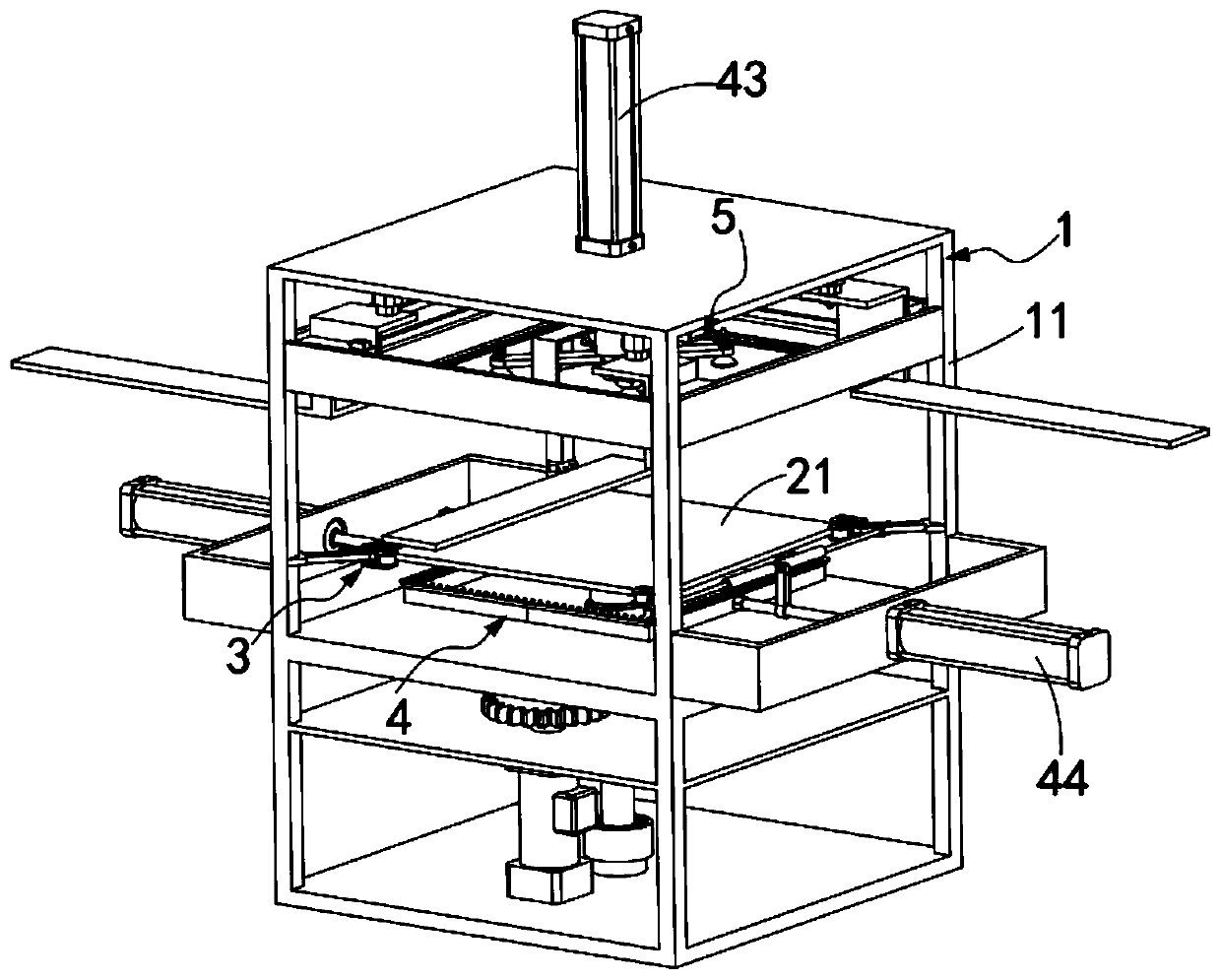

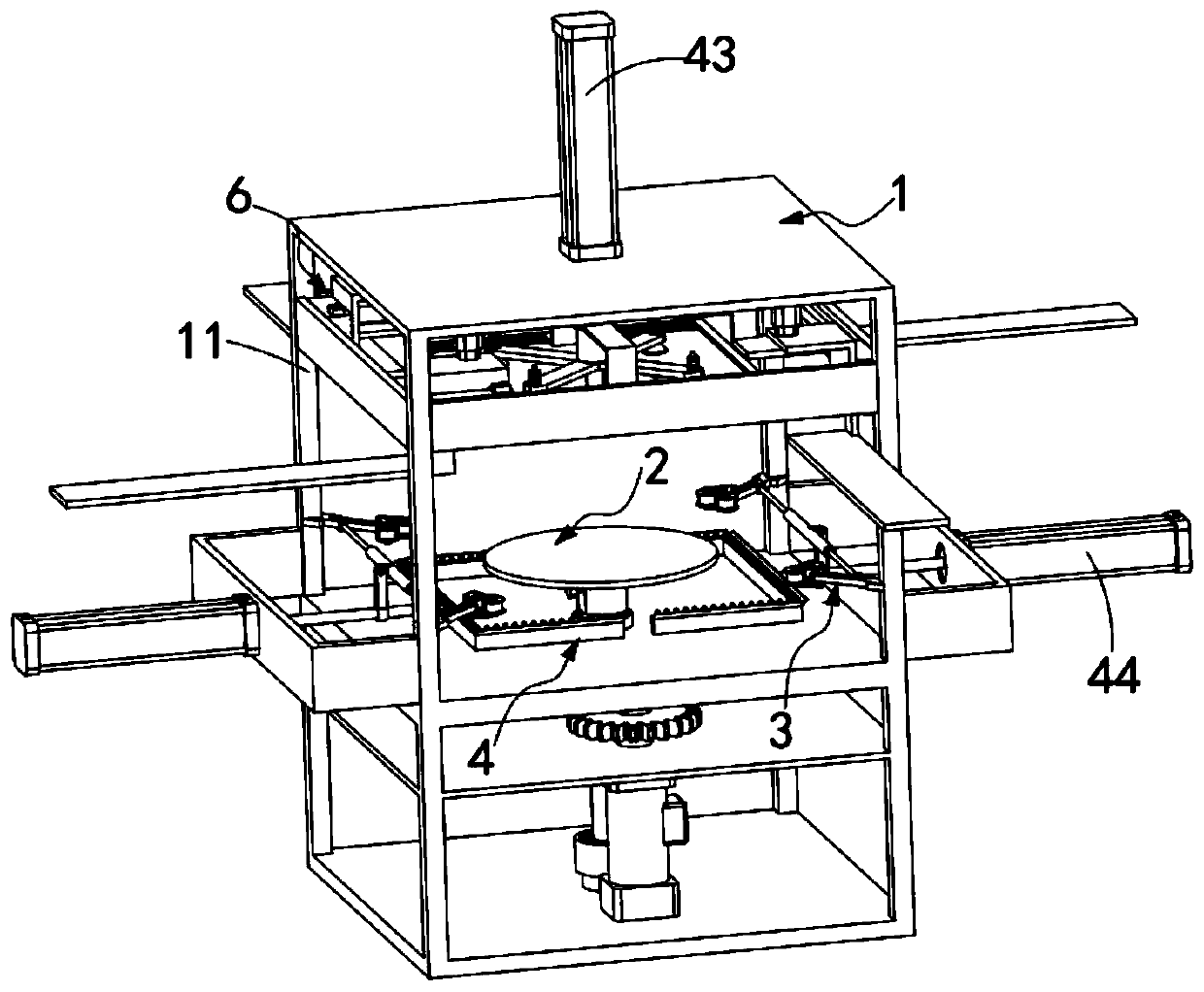

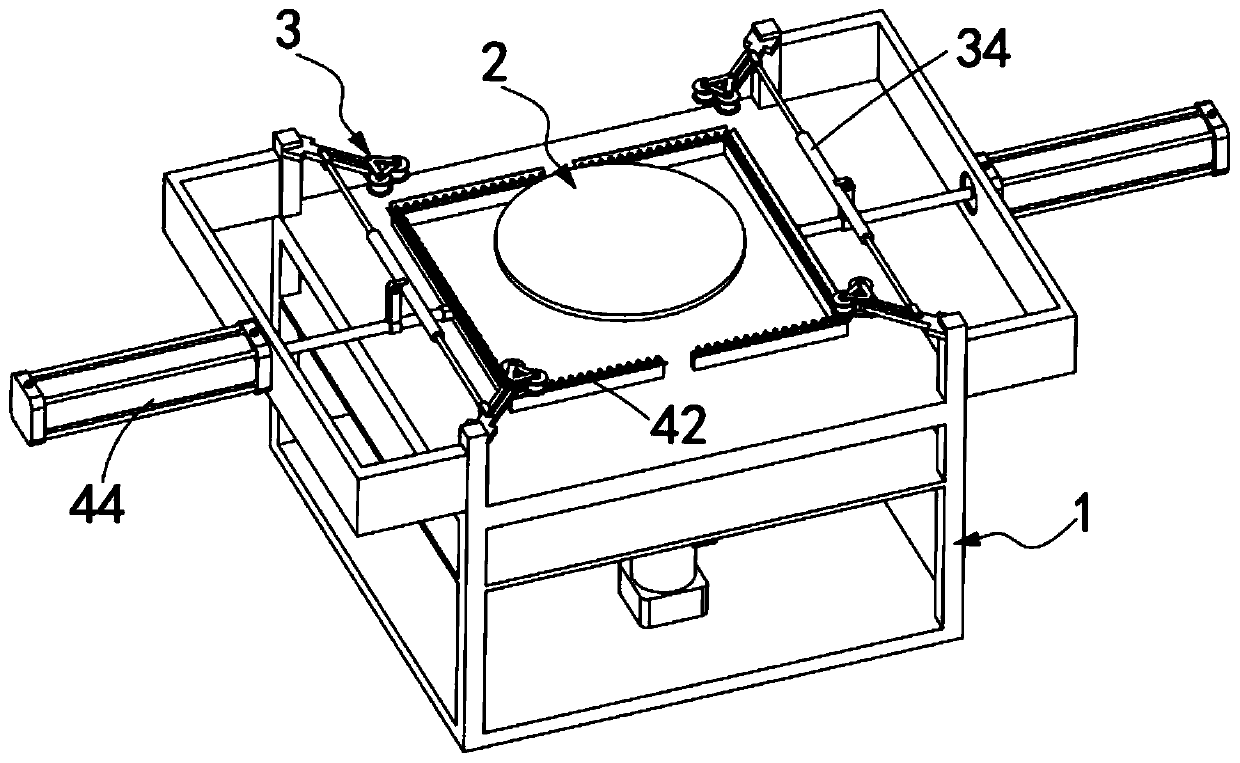

[0068] Such as Figure 1 to Figure 7 As shown, a system for cutting and reusing damaged TPT sheets for photovoltaic power generation system production includes a frame 1 set in a frame, and also includes:

[0069] A workbench 2, the workbench 2 is rotatably arranged on the frame 1, and the TPT sheet 21 is horizontally placed on the workbench 2;

[0070] The positioning mechanism 3, the positioning mechanism 3 is symmetrically arranged on the four corners of the workbench 2, and it is arranged to elastically interfere with the four corners of the TPT sheet 21 placed on the workbench 2, and it is arranged with the TPT sheet 21 The collision component 31 of the collision part can be rotatably set;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com