Grinding tooth error modeling and compensation method facing grinding wheel dressing precision

A grinding wheel dressing and error modeling technology, which is applied to the components of grinding machine tools, grinding/polishing equipment, abrasive surface adjustment devices, etc. Tooth error etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0152] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0153] The gear grinding error modeling and compensation method for grinding wheel dressing accuracy provided in this embodiment includes the following steps:

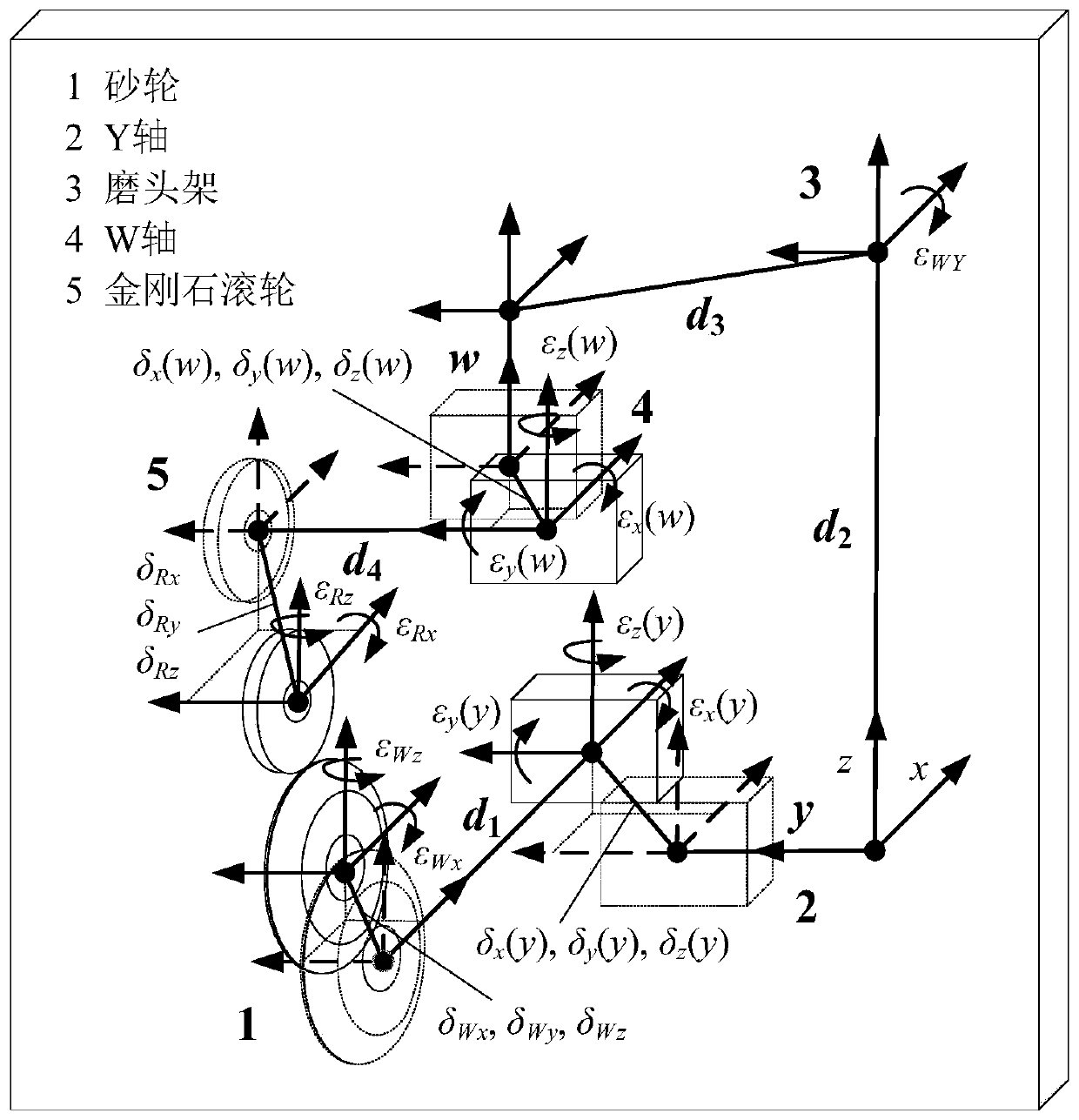

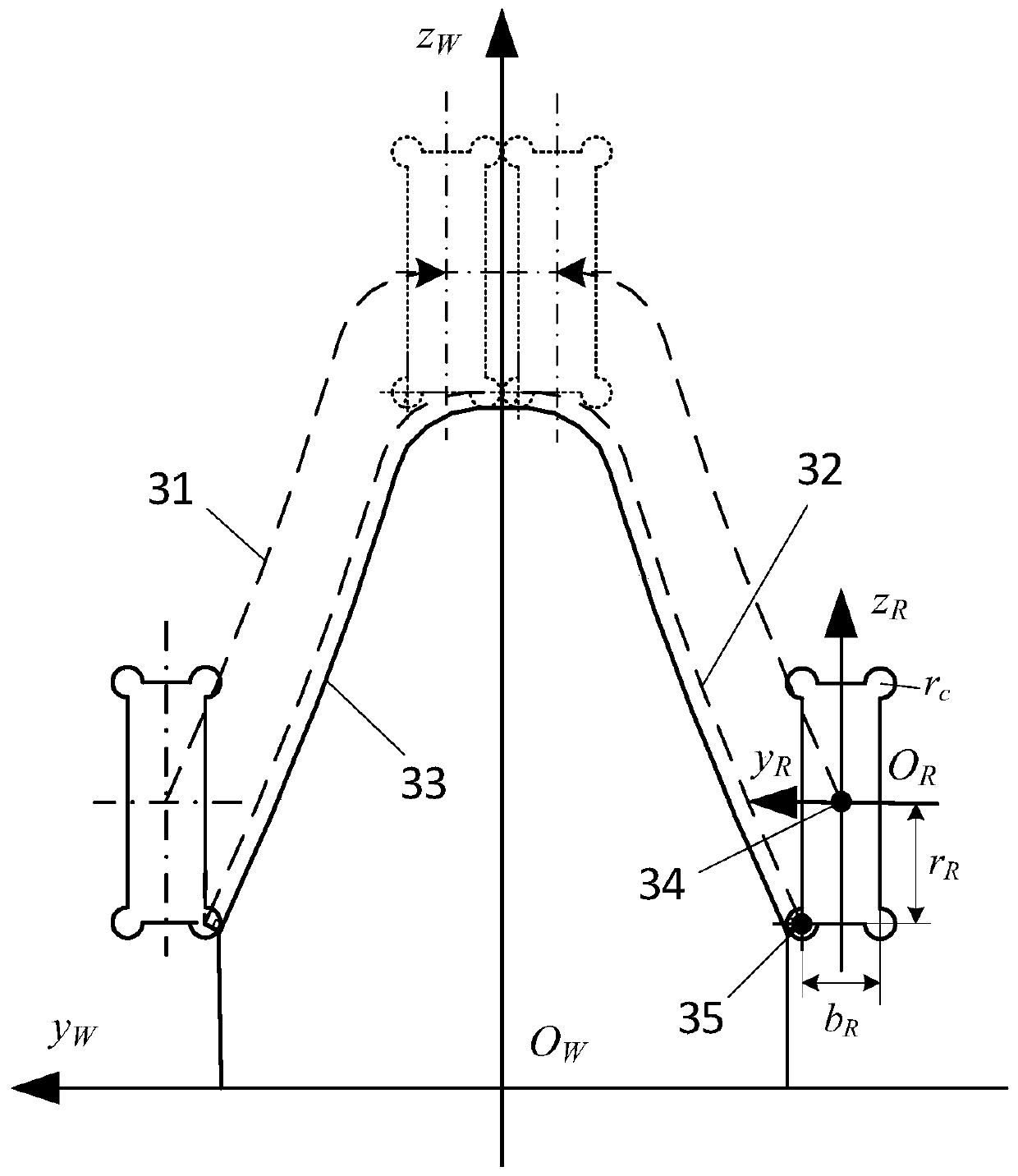

[0154] Step 1: Geometric error of grinding wheel dressing system - modeling of grinding wheel dressing error;

[0155] (1) Definition of geometric error of grinding wheel dressing system

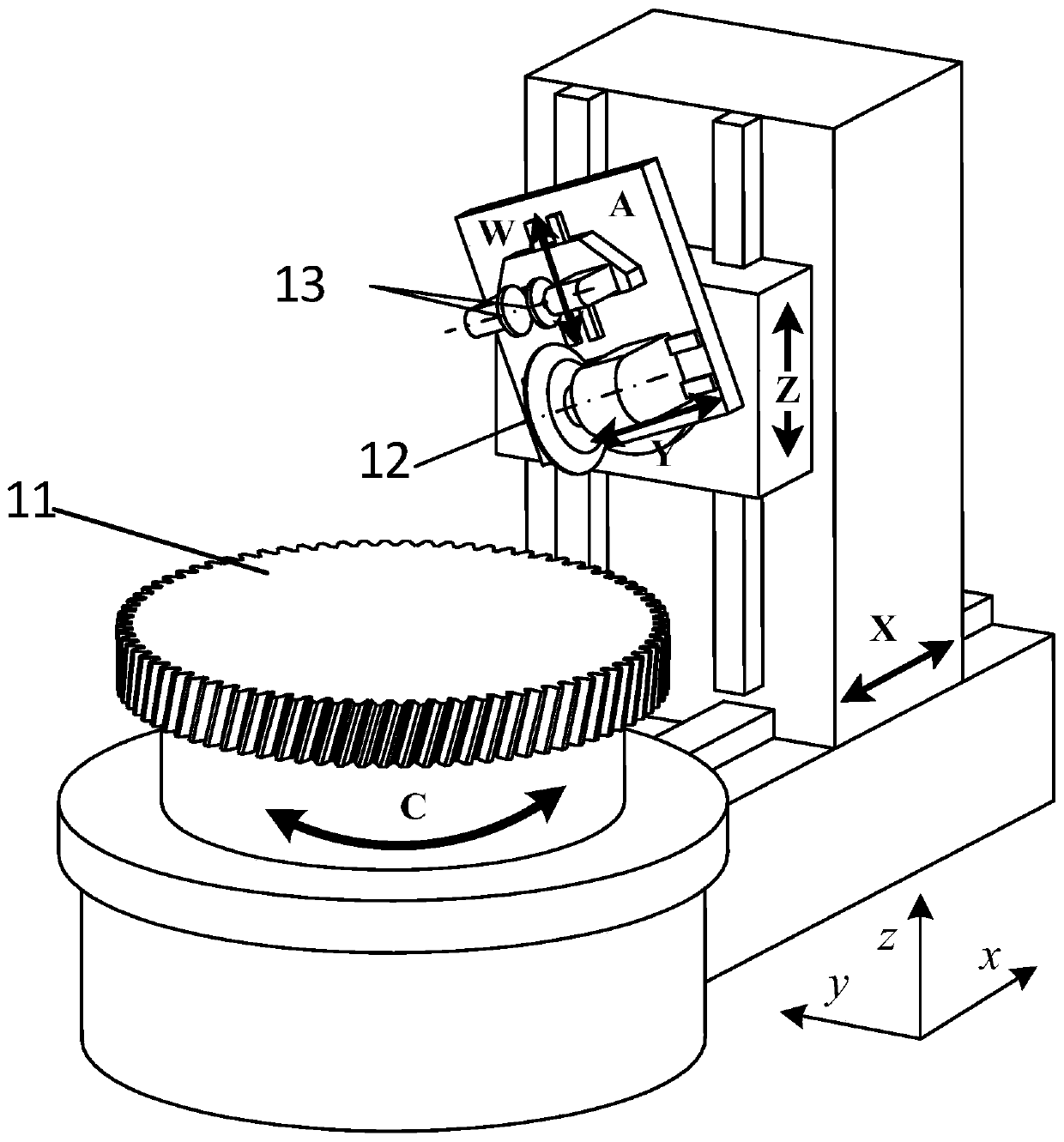

[0156] like figure 1 As shown, the profile grinding machine tool includes two relatively independent subsystems, the grinding wheel dressing system and the profile grinding system. The former is composed of grinding wheel, diamond roller, grinding head frame, W / Y dressing shaft, and the latter is composed of grinding wheel, gear blank,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap