Treatment technology used for acrylic acid and acrylate wastewater

A technology for treating acrylic acid esters and acrylic acid esters, which is applied in the field of acrylic acid and acrylic acid ester waste water treatment. It can solve the problems of high toxicity, high concentration, and complex components, and achieve the effect of reducing ammonia nitrogen and chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

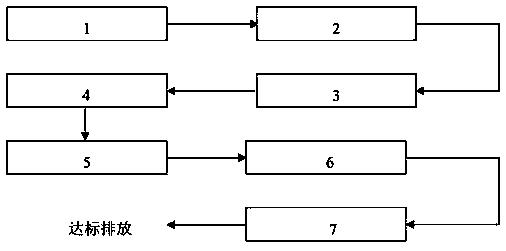

[0029] The invention discloses a treatment process applied to acrylic acid and acrylic acid ester wastewater. The treatment process includes a regulating pool, a first ABR pool, a first SBR pool, a first intermediate pool, a second ABR pool, a second SBR pool, a second The second intermediate pool: the wastewater is treated with EMO compound microorganisms in the regulating pool and then flows into the first ABR pool, the first SBR pool, the first intermediate pool, the second ABR pool, and the second SBR pool for biochemical treatment, and finally passes through the second intermediate pool Achieve emission standards.

[0030]In this embodiment, the sewage treatment is in a dynamic equilibrium state, and its condition control is an endpoint value or a range value, and the fillers in the EMO composite microbial treatment are activated carbon and volcanic rock. The treatment conditions of the first ABR pool: control influent COD not exceeding 14000mg / L, total salinity not excee...

Embodiment 2

[0032] The invention discloses a treatment process applied to acrylic acid and acrylic acid ester wastewater. The treatment process includes a regulating pool, a first ABR pool, a first SBR pool, a first intermediate pool, a second ABR pool, a second SBR pool, a second The second intermediate pool: the wastewater is treated with EMO compound microorganisms in the regulating pool and then flows into the first ABR pool, the first SBR pool, the first intermediate pool, the second ABR pool, and the second SBR pool for biochemical treatment, and finally passes through the second intermediate pool Achieve emission standards.

[0033] In this embodiment, the sewage treatment is in a dynamic equilibrium state, and its condition control is an endpoint value or a range value, and the fillers in the EMO composite microbial treatment are activated carbon and volcanic rock. The treatment conditions of the first ABR pool: control influent COD not exceeding 15000mg / L, total salinity not exce...

Embodiment 3

[0035] The invention discloses a treatment process applied to acrylic acid and acrylic acid ester wastewater. The treatment process includes a regulating pool, a first ABR pool, a first SBR pool, a first intermediate pool, a second ABR pool, a second SBR pool, a second The second intermediate pool: the wastewater is treated with EMO compound microorganisms in the regulating pool and then flows into the first ABR pool, the first SBR pool, the first intermediate pool, the second ABR pool, and the second SBR pool for biochemical treatment, and finally passes through the second intermediate pool Achieve emission standards.

[0036] In this example, the fillers in the EMO complex microbial treatment are activated carbon and volcanic rock. The treatment conditions of the first ABR pool: control influent COD not exceeding 14800mg / L, total salinity not exceeding 4%, C:N:P 100:5:1, pH control at 8.5-9.5, water temperature not exceeding 35°C , control the pH of the effluent at 6.5-7, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com