Structural steel with yield strength of 345MPa and high fatigue strength as well as manufacturing method of structural steel

A manufacturing method and technology for structural steel, applied in the field of iron and steel smelting, can solve problems such as increased cost and increased fatigue strength, and achieve the effects of increasing energy storage, improving fatigue performance, and being beneficial to fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]A yield 345MPa high-fatigue structural steel and its manufacturing method provided in this example, the chemical composition and mass percentage are as follows: C: 0.14%, Mn: 1.30%, Nb: 0.028%, Alt: 0.022%, Ti: 0.003% , Si: 0.07%, P: 0.008%, S: 0.005%, and the balance is iron and unavoidable impurities.

[0046] The thickness of the slab is 150mm, the heating temperature is 1145°C, the heating rate is 8min / cm according to the thickness of the slab, the total time is 120min, and the soaking time is 30min;

[0047] Odd-pass rolling is adopted, the thickness of the finished product is 6mm, and the thickness of the billet to be warmed is set to 7.0 times the thickness of the finished product;

[0048] The starting temperature of the finishing rolling is controlled at 1020°C, and the total rolling passes are 13 passes, of which the last 3 passes of the finishing rolling have a cumulative deformation of 45%, and the deformation of the last pass is 12%. The finishing rolling te...

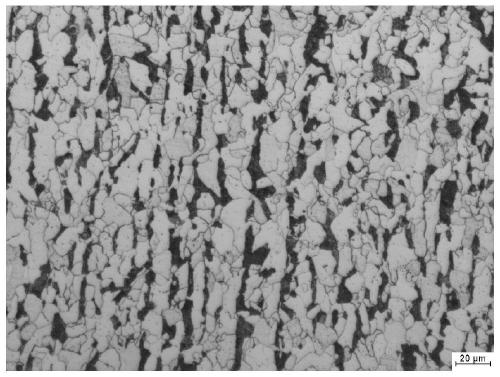

Embodiment 2

[0051] A high-fatigue structural steel with a yield of 345MPa and its manufacturing method provided in this embodiment, the chemical composition and mass percentage are as follows: C: 0.13%, Mn: 1.52%, Nb: 0.025%, Alt: 0.020%, Ti: 0.004% , Si: 0.12%, P: 0.010%, S: 0.003%, and the balance is iron and unavoidable impurities.

[0052] The thickness of the slab is 220mm, the heating temperature is 1130°C, the heating rate is 10min / cm according to the thickness of the slab, the total time is 220min, and the soaking time is 45min;

[0053] Odd-pass rolling is adopted, the thickness of the finished product is 12mm, and the thickness of the billet to be warmed is set to 4.0 times the thickness of the finished product;

[0054] The starting temperature of the finish rolling is controlled at 1020°C, and the total rolling passes are 11 passes, of which the last 3 passes of the finish rolling have a cumulative deformation of 46%, and the deformation of the last pass is 12%. The finishing ...

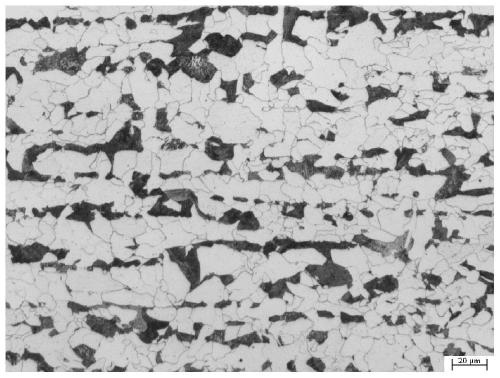

Embodiment 3

[0057] A high fatigue structural steel with a yield of 345MPa and its manufacturing method provided in this embodiment, the chemical composition and mass percentage are as follows: C: 0.16%, Mn: 1.55%, Nb: 0.035%, Alt: 0.021%, Ti: 0.003% , Si: 0.07%, P: 0.008%, S: 0.004%, and the balance is iron and unavoidable impurities.

[0058] The thickness of the slab is 220mm, the heating temperature is 1150°C, the heating rate is 9min / cm according to the thickness of the slab, the total time is 198min, and the soaking time is 60min;

[0059] Odd pass rolling is adopted, the thickness of the finished product is 22mm, and the thickness of the billet to be warmed is set to 3.2 times the thickness of the finished product;

[0060] The starting temperature of the finish rolling is controlled at 980°C, and the total rolling passes are 11 passes, of which the last 3 passes of the finish rolling have a cumulative deformation of 43%, and the deformation of the last pass is 11%. The finishing ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fatigue limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com