An easy-to-operate needle row replacement device for a carding machine

A technology for replacing equipment and needle-carding machines. It is applied in the fields of combing machines, textile and papermaking, and fiber processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

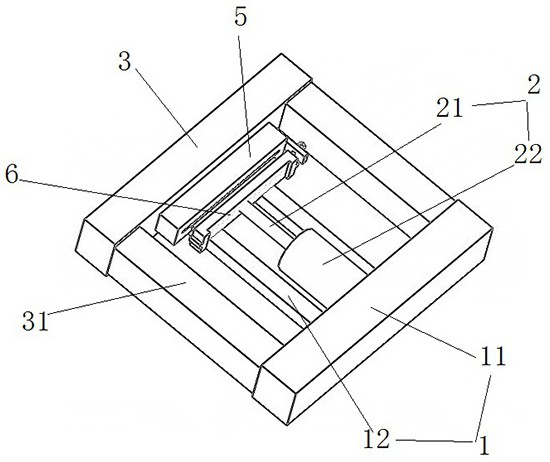

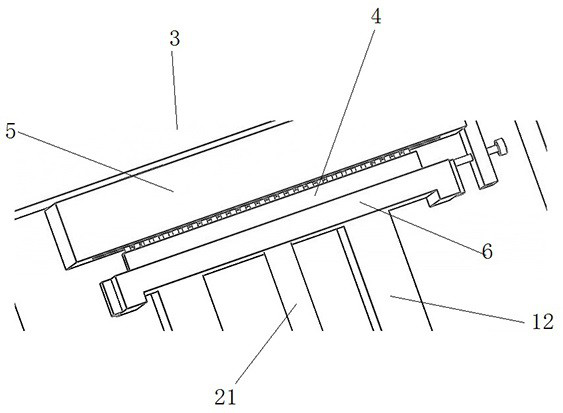

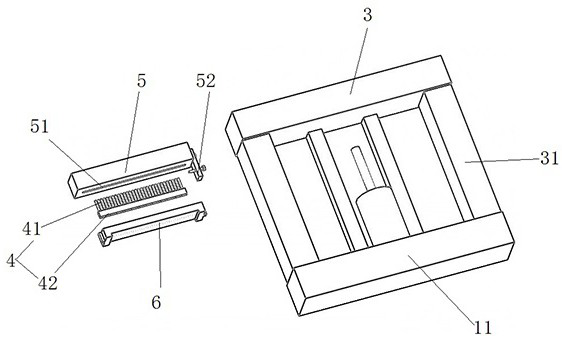

[0032] Such as Figure 1~5 As shown, an easy-to-operate needle row replacement device for a carding machine includes a frame body 1, a cylinder 2 installed on the frame body 1, a stopper located on the travel route of the piston rod 21 of the cylinder 2 and perpendicular to the travel route. Seat 3 and the fixed box 5 for accommodating the fixed needle row 4, the frame body 1 includes the mounting seat 11 arranged at the bottom end of the cylinder body 22 of the cylinder 2 and the mounting seat 11 fixed on the mounting seat 11 and located on both sides of the cylinder 2. The parallel connecting rod 12 clamped by the cylinder 2 on the side, the stopper 3 is fixedly connected with the ends of the two connecting rods 12, and the fixed box 5 is a strip-shaped metal block, the middle of which is along its length A needle groove 51 for inserting the comb needles 41 of the needle row 4 is provided in the direction, and the thickness of the needle groove 51 is smaller than the thickne...

Embodiment 2

[0042] This embodiment is based on embodiment 1, and its technical scheme is basically the same as embodiment 1, the difference is:

[0043]In this embodiment, the thickness of the fixed box 5 is greater than the thickness of the needle plate 6, and the present invention is also provided with several gaskets (not shown in the figure) with a smaller thickness, and the thickness of the gaskets is 0.5 ~ 1 mm, preferably 0.5 mm in this embodiment, by placing several pieces of the gaskets under the needle plate 6, the height of the installation groove 61 of the needle plate 6 is adjusted, which is convenient for the installation groove 61 and Alignment of needle shaft 42.

Embodiment 3

[0045] This embodiment is based on embodiment 1, and its technical scheme is basically the same as embodiment 1, the difference is:

[0046] Such as Figure 7 As shown, the bottom of the cylinder body 22 of the cylinder 2 is attached to the mounting seat 11, and a pressure sensor 71 is also arranged between the cylinder 2 and the mounting seat 11, and the pressure sensor 71 is connected to an ECU controller. 72. The ECU controller 72 is electrically connected to the cylinder 2, and the ECU controller 72 is preset with a safety pressure value. When the cylinder 2 is running and the piston rod 21 pushes the needle plate 6, the pressure sensor 71 will detect When the needle bar 6 and the needle bar 4 are gradually installed closer to the pressure value, the pressure value will gradually increase until the needle bar 4 and the needle bar 6 are installed. At this time, the cylinder 2 will continue to work. When the When the pressure value detected by the pressure sensor 71 reaches...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com