Hollow fiber durability water-repellent finishing method

A water-repellent finishing and durability technology, applied in fiber treatment, liquid repellent fibers, textiles and papermaking, etc., to avoid friction loss, prolong retention time, and improve water-repellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The fibers to be finished are 1.5Dⅹ38mm Porel polyester hollow fibers, and the water-repellent agent is TEXNOLOGY TM FB205, C6 water-repellent agent.

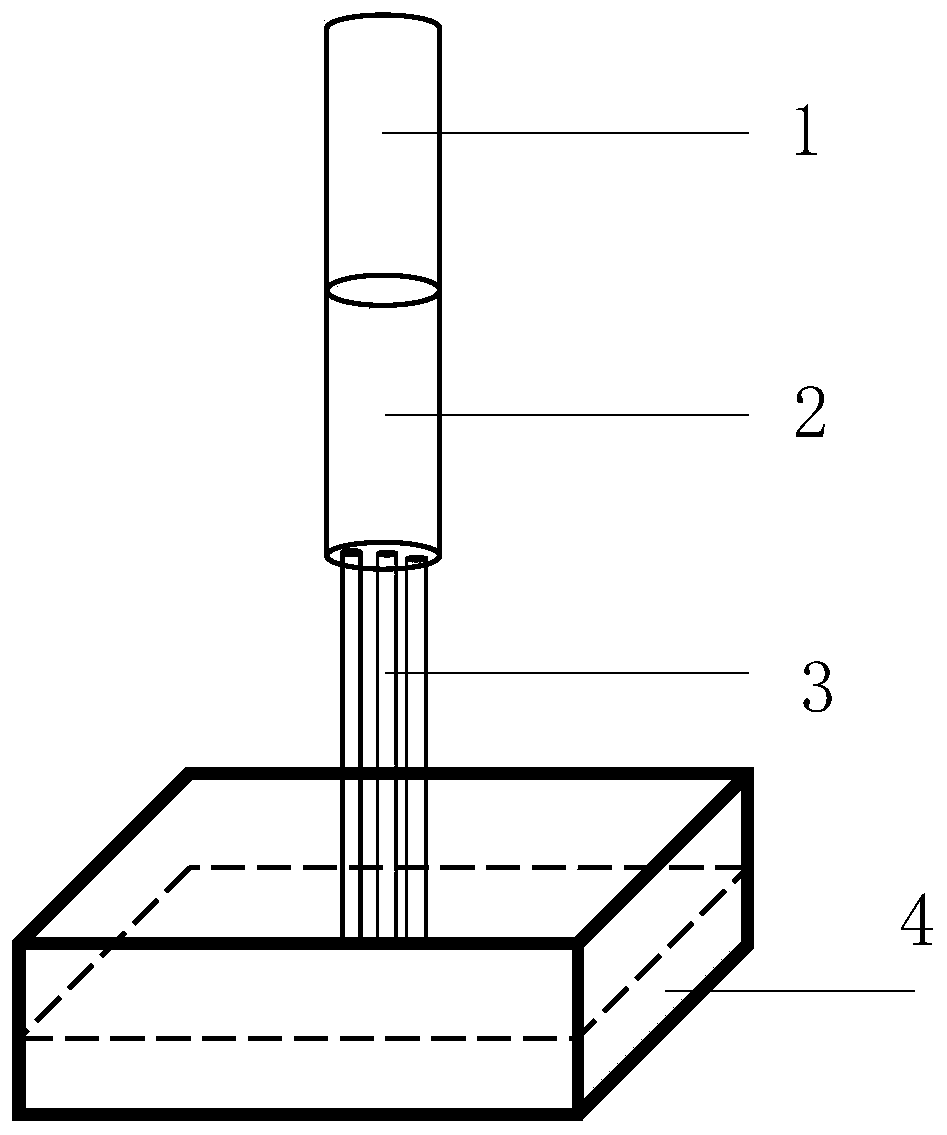

[0033] ① Connect the air inlet nozzle 1 of the vacuum pump to the upper end of the perspective tube 2 in a sealed connection, and the bottom of the lower end of the perspective tube 2 is provided with uniform small holes arranged in parallel, insert the upper end of the hollow fiber bundles 3 arranged in parallel into the small holes at the bottom of the perspective tube 2, and the hollow fiber bundles 3 The lower end is immersed in the water-repellent agent 4.

[0034] ② Turn on the vacuum pump, the pumping rate of the vacuum pump is 2L / S, and the ultimate vacuum is 10Pa, until the water-repellent agent leaks from the upper end of the hollow fiber bundle in the perspective tube, then turn off the vacuum pump.

[0035] ③Pre-dry the hollow fiber bundle filled with water repellent agent in the cavity, the pre-bake temperat...

Embodiment 2

[0039] The fibers to be finished are 1.5Dⅹ38mm Porel polyester hollow fibers, and the water-repellent agent is TEXNOLOGY TM FB205, C6 water-repellent agent.

[0040] ① Connect the air inlet nozzle 1 of the vacuum pump to the upper end of the perspective tube 2 in a sealed connection, and the bottom of the lower end of the perspective tube 2 is provided with uniform small holes arranged in parallel, insert the upper end of the hollow fiber bundles 3 arranged in parallel into the small holes at the bottom of the perspective tube 2, and the hollow fiber bundles 3. The lower end is immersed in the water repellent agent 4.

[0041] ② Turn on the vacuum pump, the pumping rate of the vacuum pump is 2L / S, and the ultimate vacuum is 10Pa, until the water-repellent agent leaks from the upper end of the hollow fiber bundle in the perspective tube, then turn off the vacuum pump.

[0042] ③Pre-dry the hollow fiber bundle filled with water-repellent agent in the cavity, the pre-drying tempe...

Embodiment 3

[0046] The fibers to be finished are 1.5Dⅹ38mm Porel polyester hollow fibers, and the water-repellent agent is TEXNOLOGY TM FB205, C6 water-repellent agent.

[0047]①The air inlet nozzle 1 of the vacuum pump is sealed and connected with the see-through tube 2, and the lower end of the see-through tube 2 is provided with uniform small holes arranged in parallel, and the upper end of the parallel-arranged hollow fiber bundle 3 is inserted into the small hole at the bottom of the see-through tube 2, and the hollow fiber bundle 3 The lower end is immersed in the water-repellent agent 4.

[0048] ② Turn on the vacuum pump, the pumping rate of the vacuum pump is 2L / S, and the ultimate vacuum is 10Pa, until the water-repellent agent leaks from the upper end of the hollow fiber bundle in the perspective tube, then turn off the vacuum pump.

[0049] ③Pre-dry the hollow fiber bundle filled with water-repellent agent in the cavity, the pre-drying temperature is 120°C, and the pre-drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com