Sealed hydraulic tensioner

A technology for sealing hydraulic pressure and tensioners, which is applied in the sealing of engines, machines/engines, transmissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

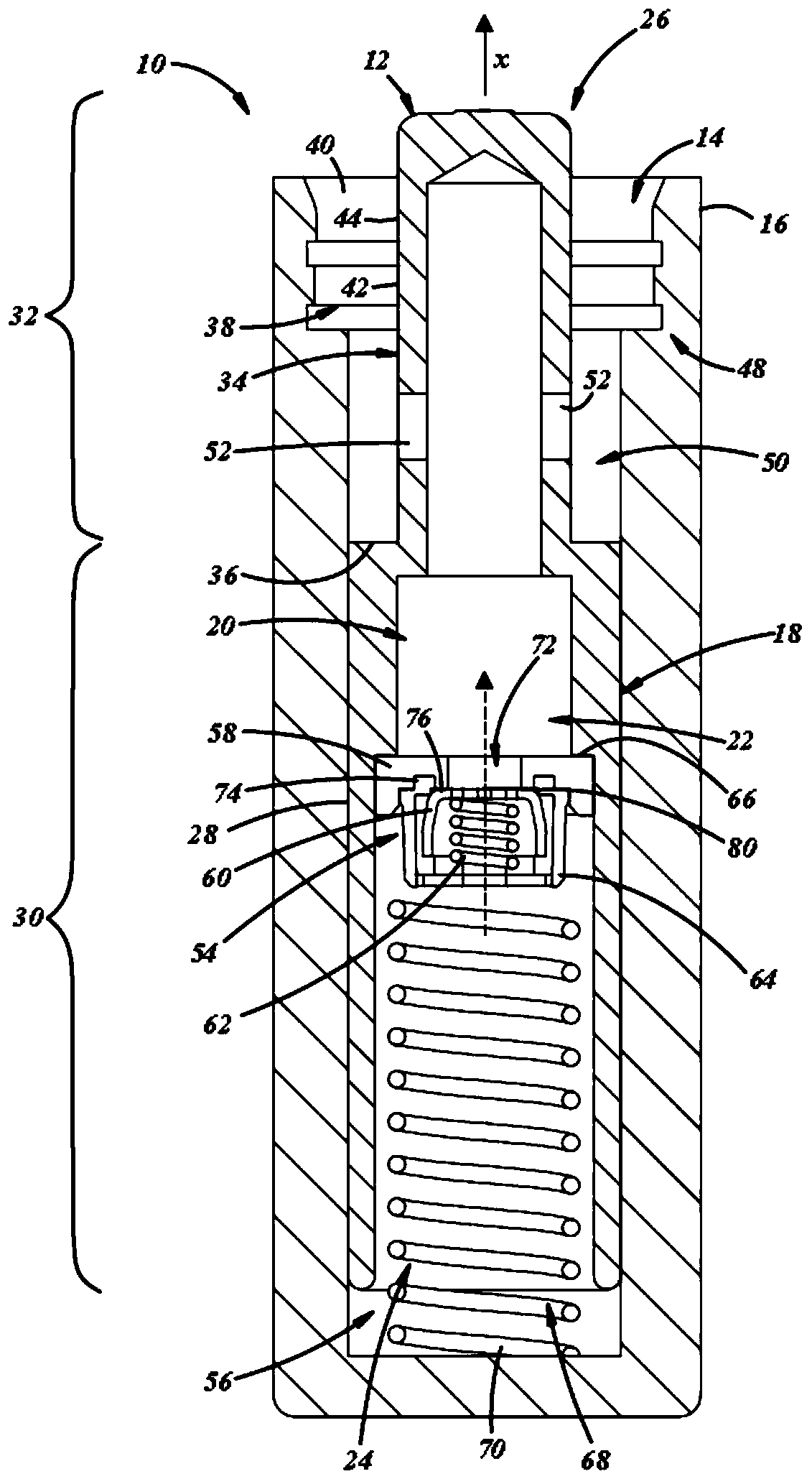

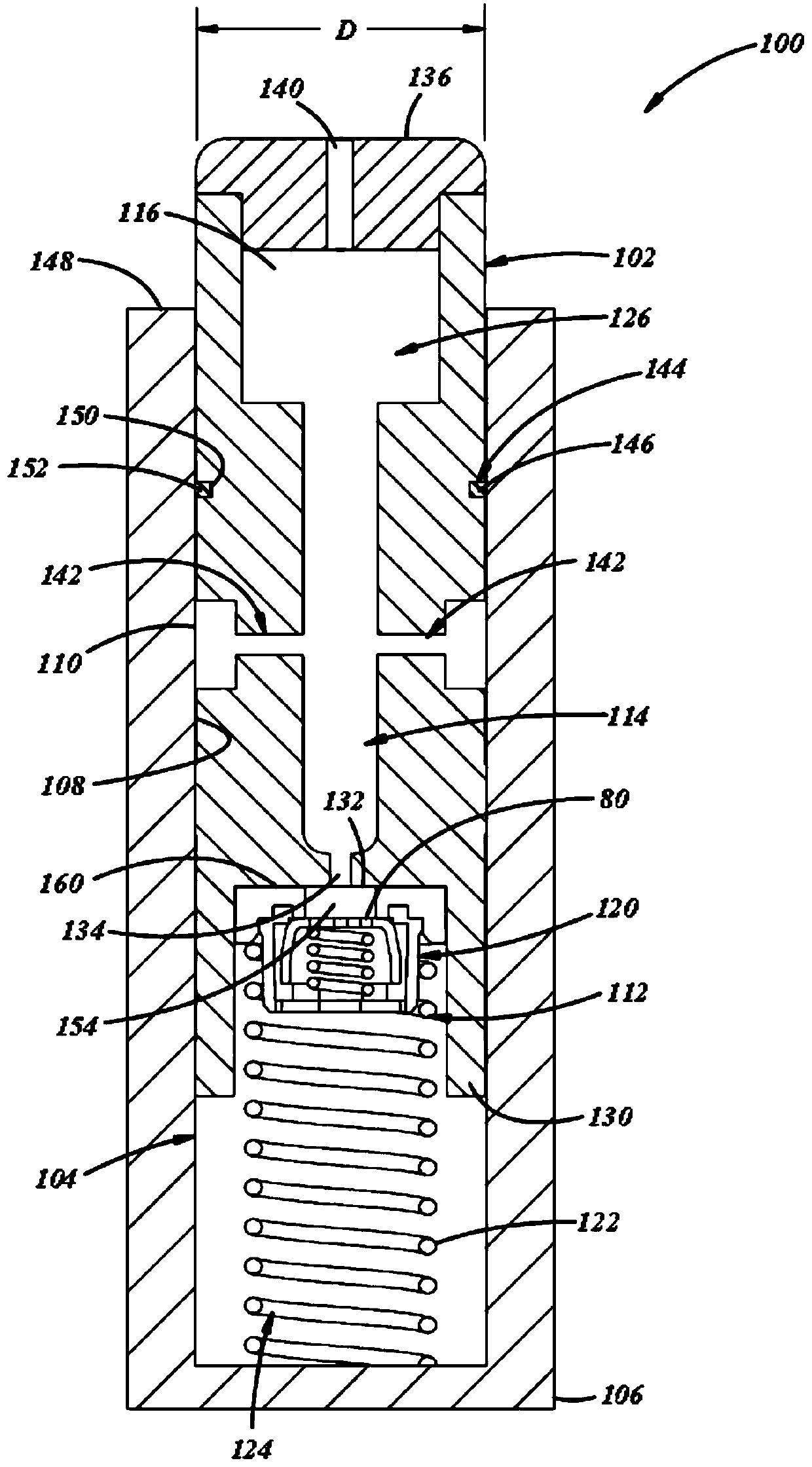

[0009] A sealed hydraulic tensioner includes a cylinder housing a piston that slides relative to the cylinder. The piston may include an inner surface defining a piston cavity. The cylinder and piston combination define an enclosed or sealed space that prevents fluid from escaping from the hydraulic tensioner. A hydraulic tensioner can be divided into a low pressure chamber and a high pressure chamber by means of a check valve and by means of the space between the closely fitting outer surfaces of the cylinder and piston. Fluid can flow between the low and high pressure chambers within the hydraulic tensioner without adding or removing fluid. The piston slides relative to the cylinder to engage the chain and increase the chain's tension around the crankshaft and camshaft sprockets. As the piston slides relative to the cylinder and extends toward the chain, fluid can flow from the low pressure chamber to the high pressure chamber. Fluid can flow from the high-pressure chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com