Wafer state detection device and method and wafer loading and unloading chamber

A state detection and wafer technology, applied in the direction of transportation and packaging, semiconductor/solid-state device manufacturing, conveyor objects, etc., can solve problems such as occlusion, normal changes, and inability to cause signals, and achieve accurate detection, ease of presence, and area increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the technical solution of the present invention, the wafer state detection equipment, method and wafer loading and unloading chamber provided by the present invention will be described in detail below with reference to the accompanying drawings.

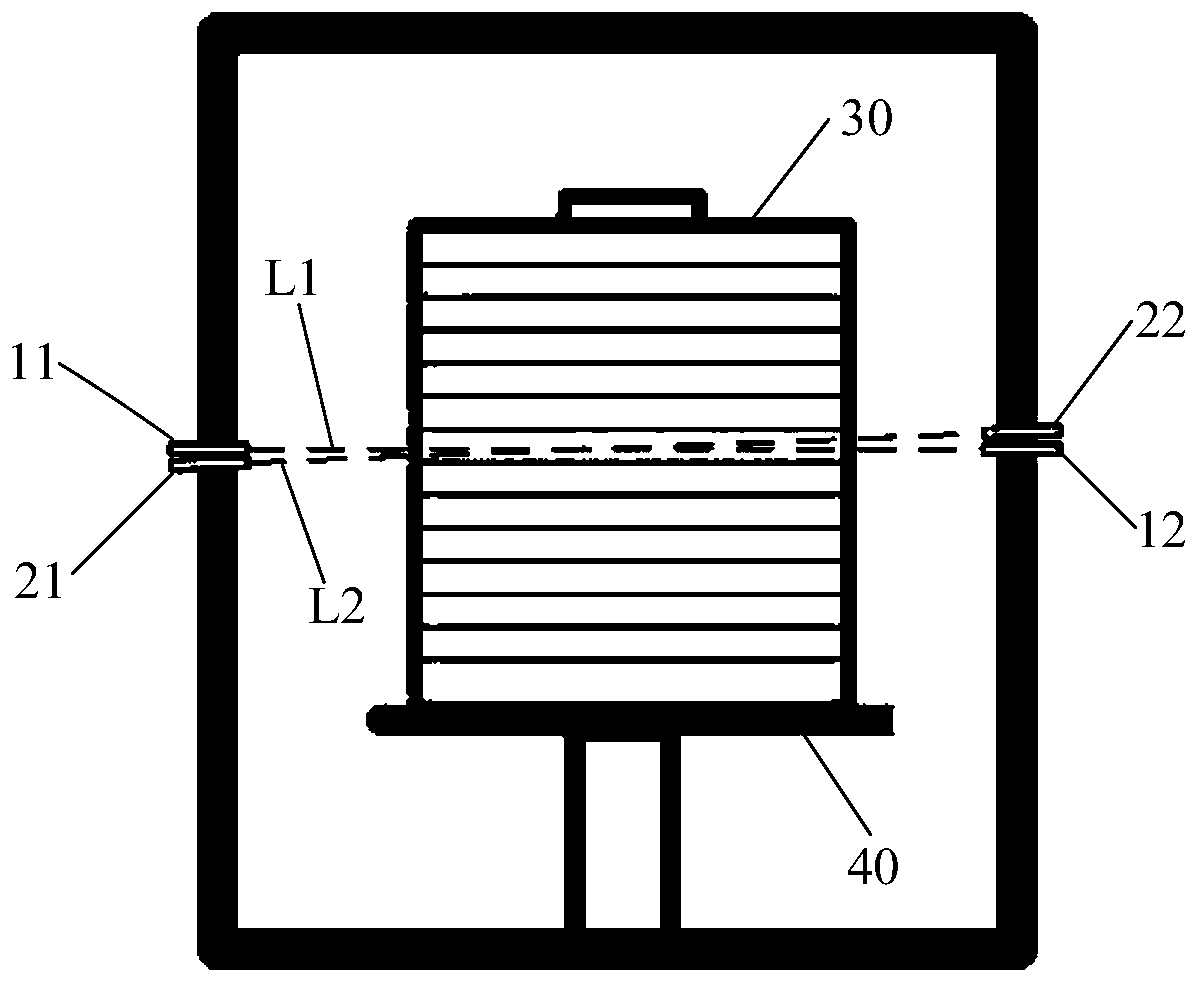

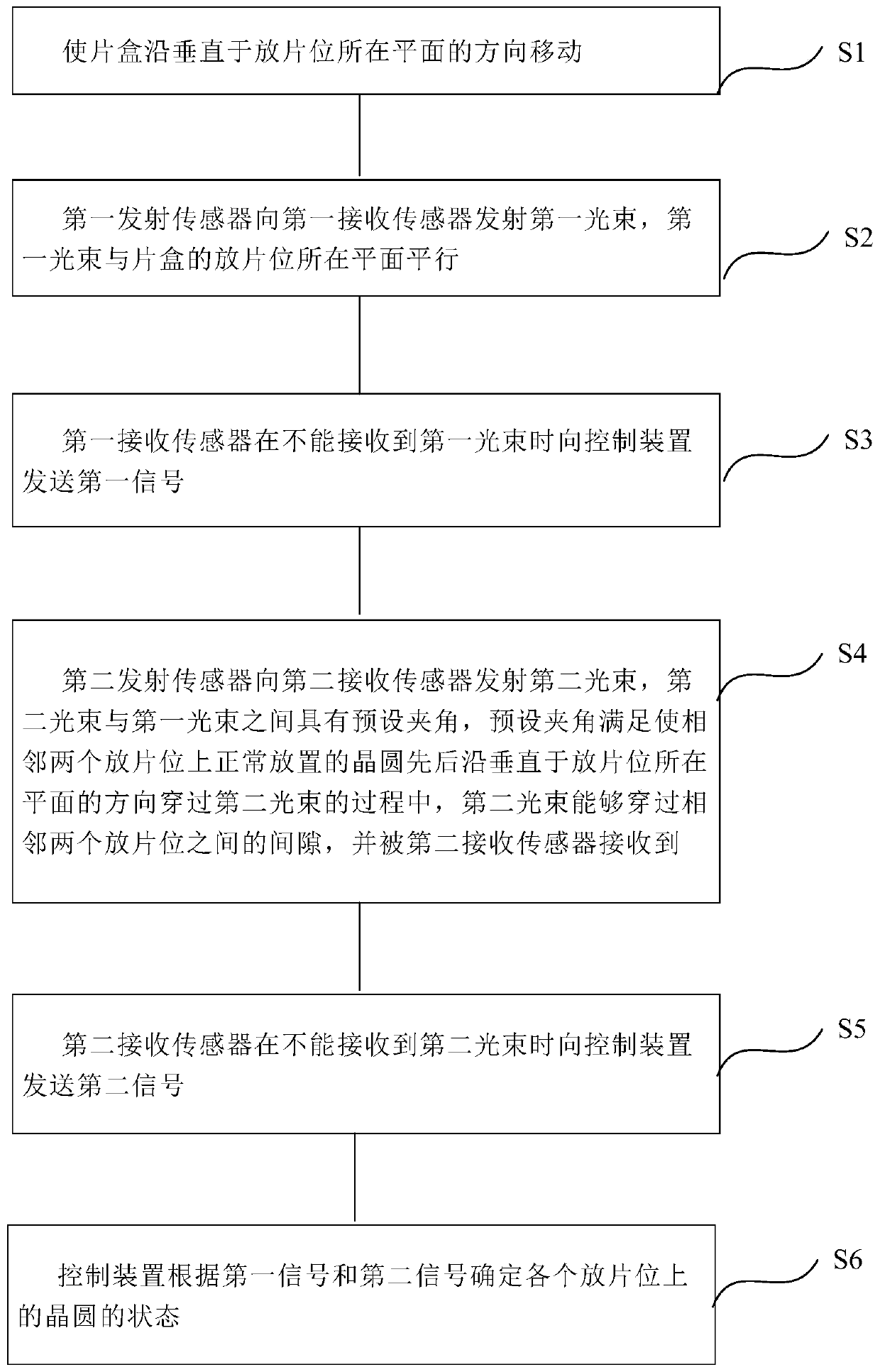

[0040] Such as figure 1As shown, this embodiment provides a wafer state detection device, including a first sensor group, a second sensor group and a control device. Wherein, the first sensor group includes a first emitting sensor 11 and a first receiving sensor 12, the first emitting sensor 11 emits a first light beam L1 to the first receiving sensor 12, and the first light beam L1 is parallel to the plane where the film position of the cassette is located . The second sensor group includes a second emitting sensor 21 and a second receiving sensor 22, the second emitting sensor 21 emits a second light beam L2 to the second receiving sensor 22, and there is a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com