High-integration charger power unit

A technology of power unit and charger, applied in the direction of current collector, electrical components, output power conversion device, etc., can solve the problems of increasing wiring complexity, increasing volume, and many interfaces, and achieving high product structure integration, reducing Effects of Design and Product Cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

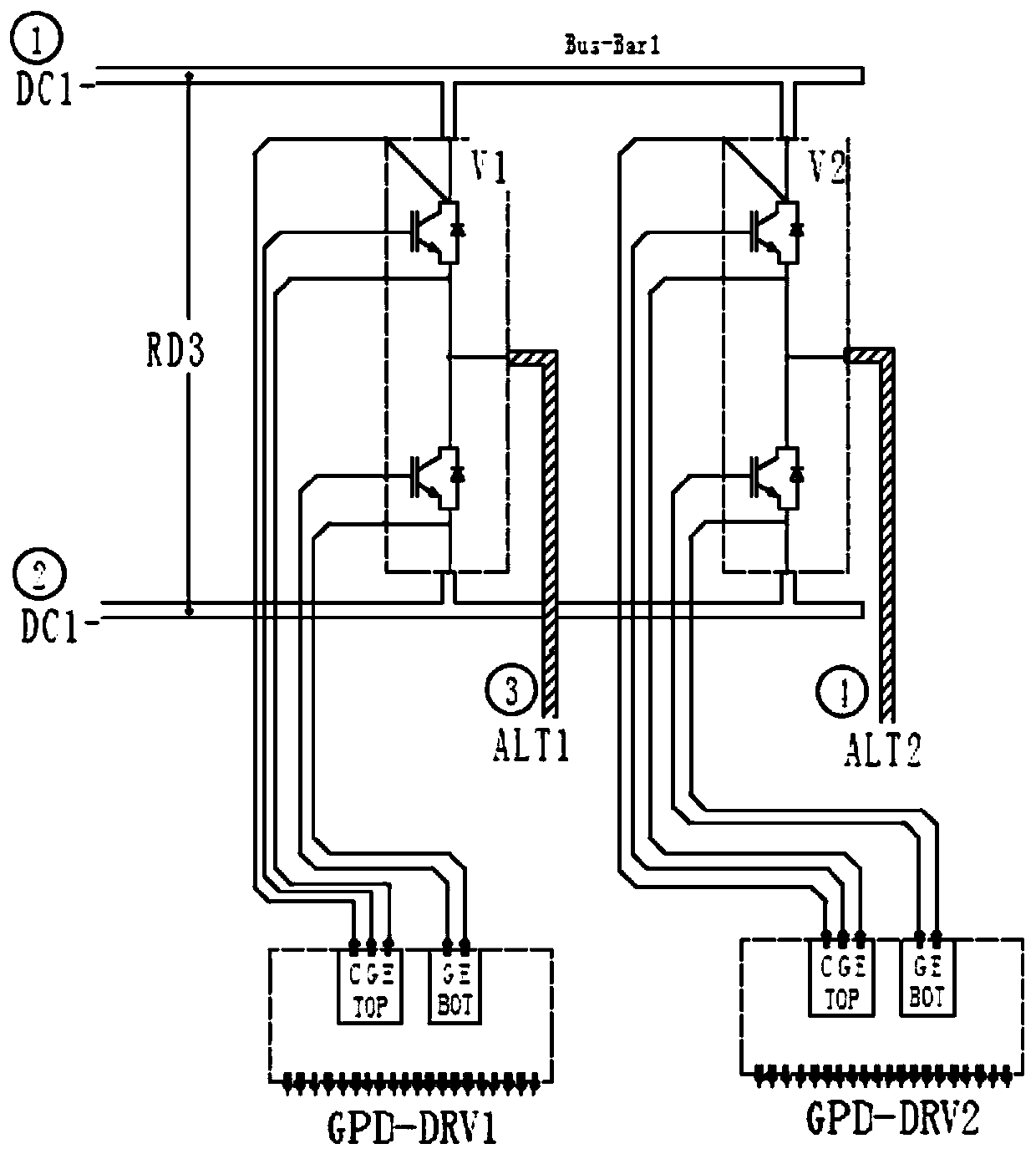

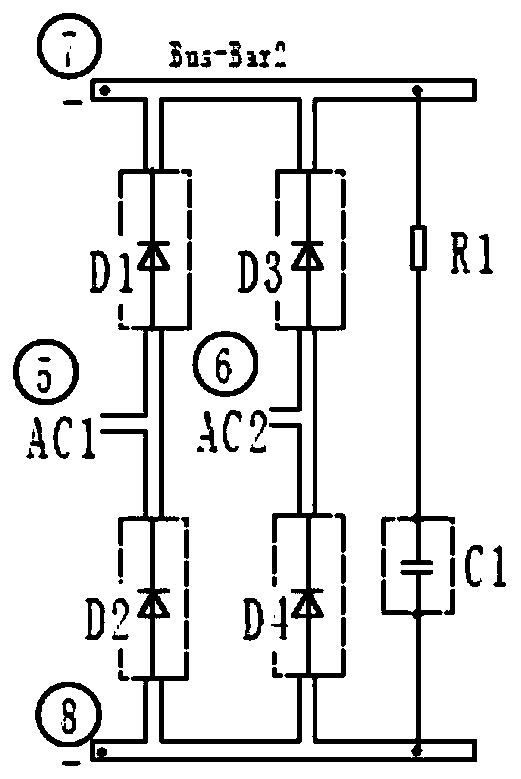

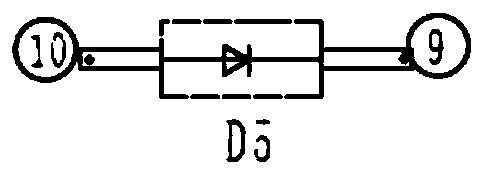

[0025] The highly integrated charger power unit of the present invention includes a frame, a water-cooled substrate installed on the frame, and a power unit installed on the water-cooled substrate; the power unit includes an inverter circuit, a rectifier circuit, an RC absorption circuit, The inverter input composite busbar, the AC output composite busbar, and the rectification composite busbar; wherein, the inverter input composite busbar is connected to the DC input of the inverter circuit, and the AC output composite busbar is connected to the The AC output of the inverter circuit is connected, and the rectification composite busbar is connected to the rectification circuit and the absorption capacitor of the RC absorption circuit.

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

[0027] The schematic circuit diagram of the present embodiment is shown in Fig. 1(a), Fig. 1(b) and Fig. 1(c):

[0028] V1-V2 are two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com