MEMS device and preparation method thereof

A device and substrate technology, applied in the field of MEMS devices and their preparation, can solve problems such as reducing the service life and performance of MEMS devices, damage life, rupture, etc., and achieve good mechanical properties, improve service life, and improve bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

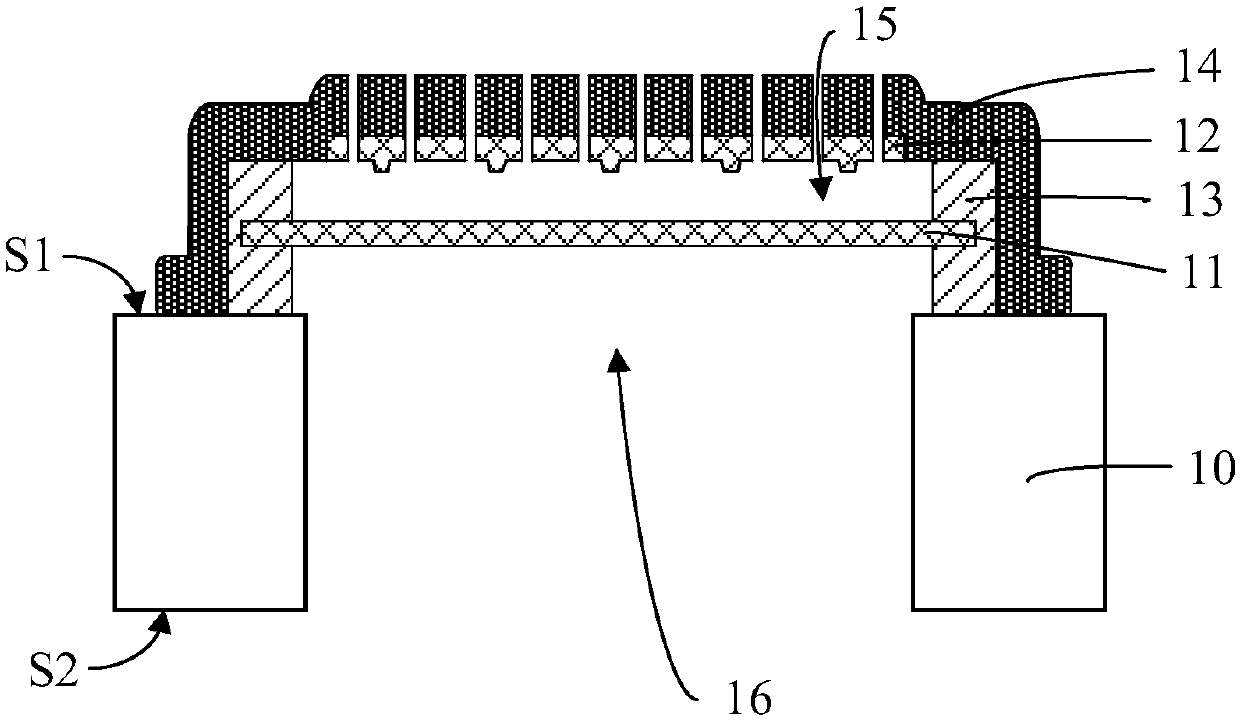

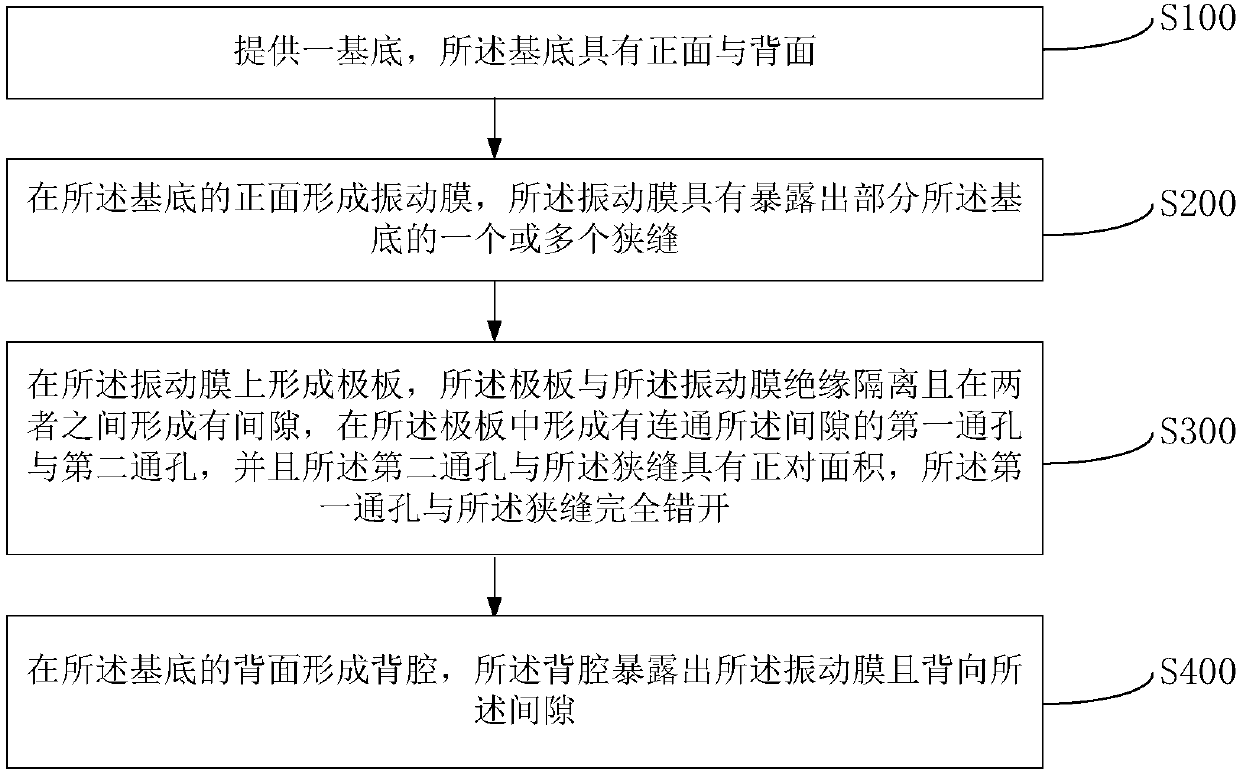

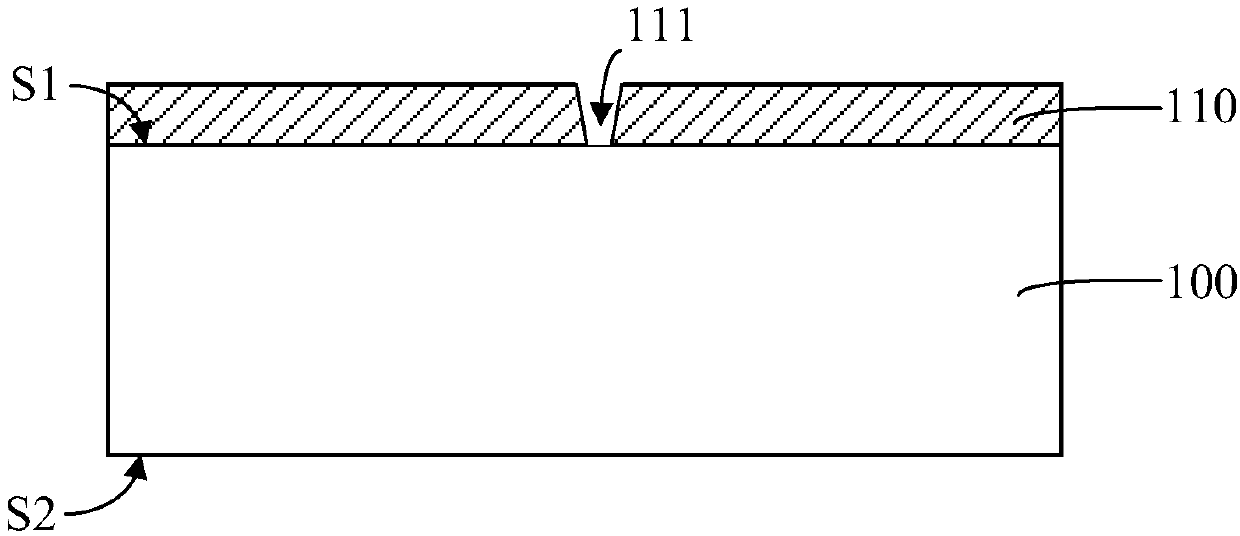

[0064] In view of the above problems, the inventors of the present application proposed a method for preparing a MEMS device, including: providing a substrate, the substrate has a front and a back; forming a vibrating membrane on the front of the substrate, and the vibrating membrane has exposed One or more slits in part of the base; a pole plate is formed on the vibrating membrane, the pole plate is insulated from the vibrating membrane and a gap is formed between the two, and a pole plate is formed in the vibrating membrane There are a first through hole and a second through hole communicating with the gap, and the second through hole and the slit have a facing area, and the first through hole and the slit are completely staggered; The back side of the substrate forms a back cavity exposing the diaphragm and facing away from the gap.

[0065] In the preparation method of the MEMS device provided by the present invention, one or more slits exposing the base are formed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com