An industrial vehicle cab comprising a step lighting system, a body component with a lighting system, and associated industrial vehicle

A technology for lighting systems and industrial vehicles, applied in the field of industrial vehicles, can solve the problems of lighting efficiency, compactness, and unsatisfactory costs, etc., and achieve the effects of less space, reduced risk of damage, and enhanced safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

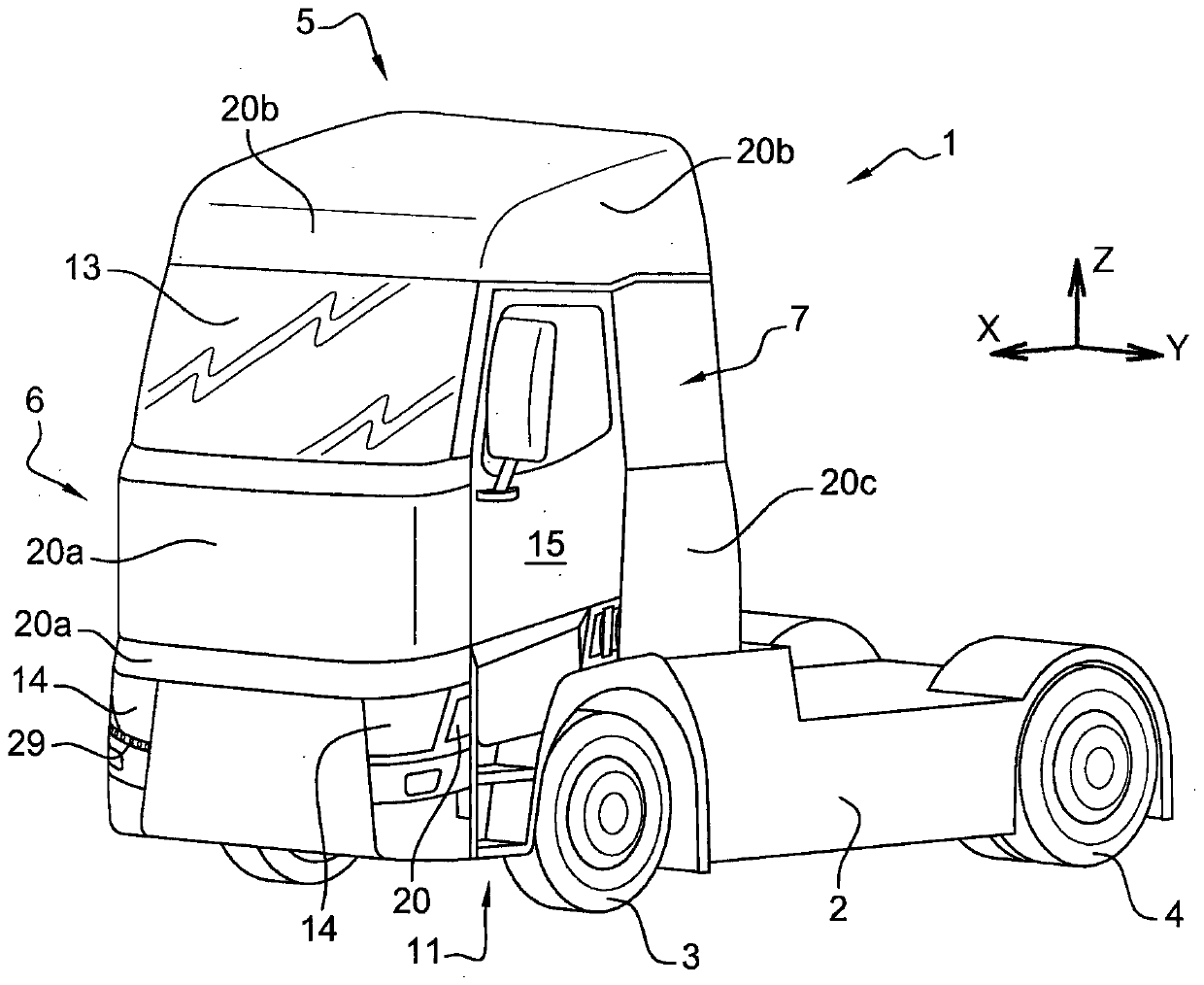

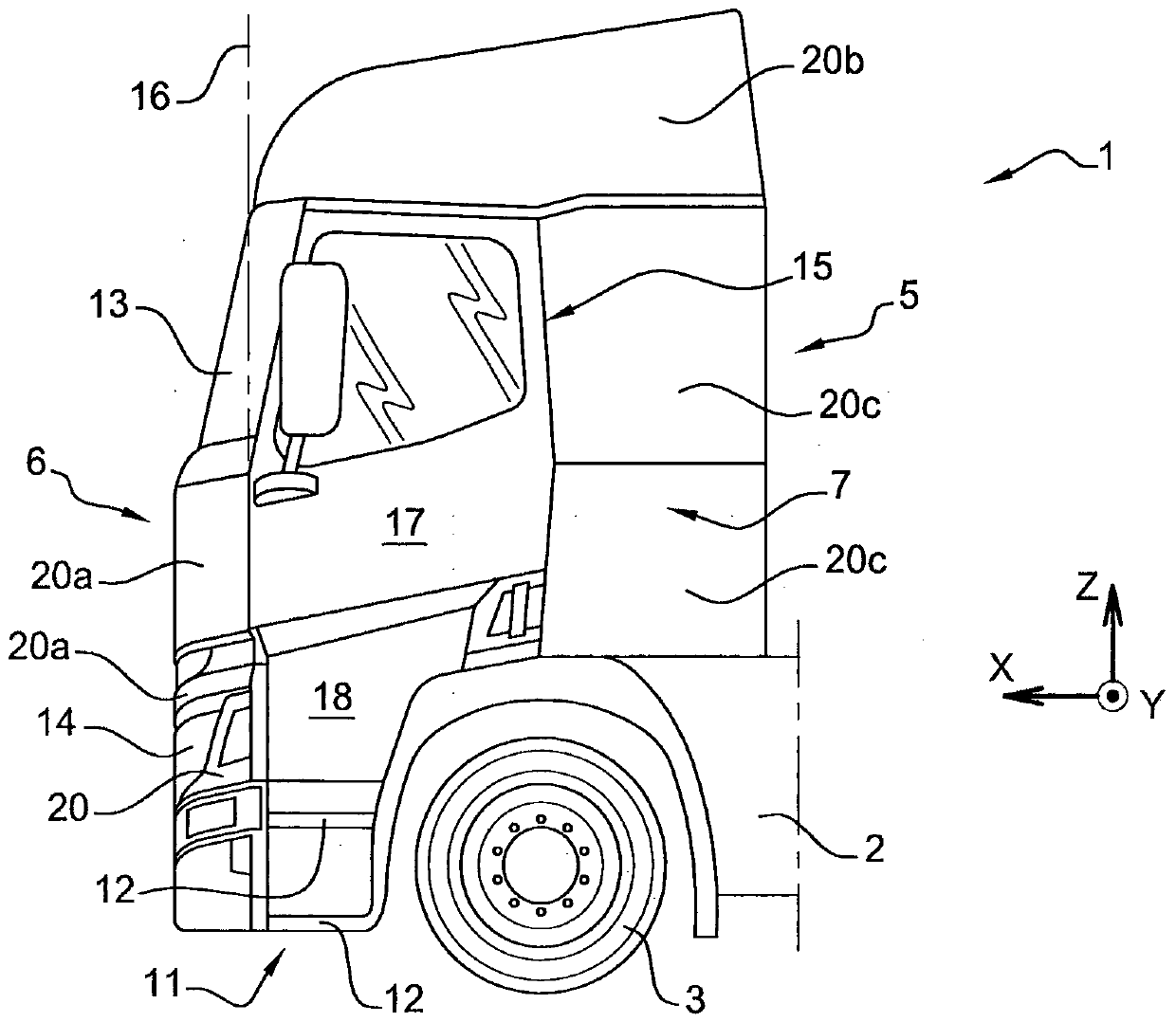

[0045] figure 1 A vehicle 1 is shown, more specifically an industrial vehicle. Although the invention will be described in relation to a truck, the invention is not limited to this particular vehicle, but may also be used in other vehicles, such as buses.

[0046] Vehicle 1 includes a body frame 2 supported by front wheels 3 and rear wheels 4 , and a cab 5 . The vehicle 1 may also include a cargo box (not shown). Z is defined as the vertical direction, X is defined as the longitudinal direction of the vehicle 1 , and Y is defined as the lateral direction of the vehicle 1 .

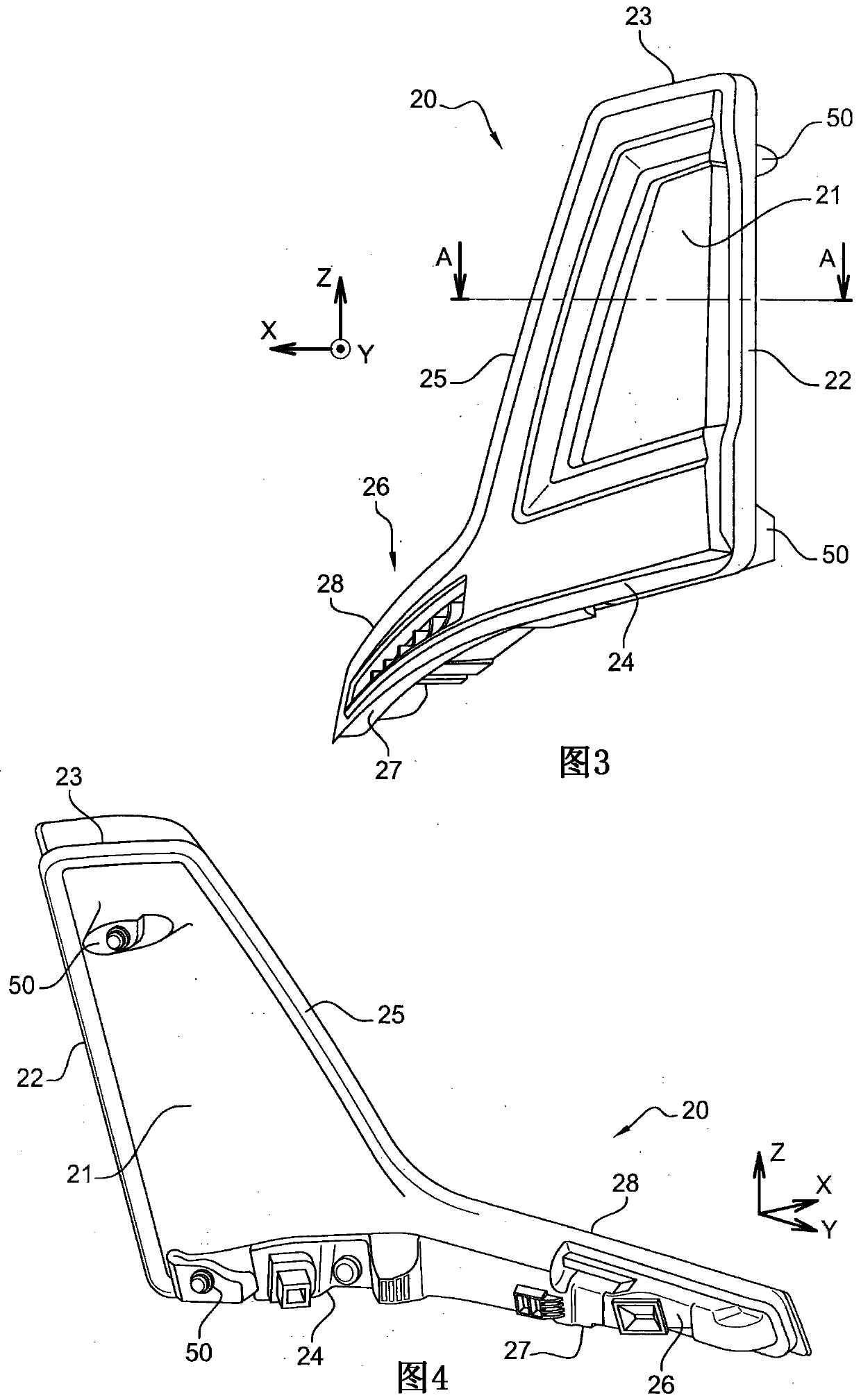

[0047]The cab 5 has a front wall 6 and two side walls 7 . The cab 5 defines a driver's compartment 8 with a floor 9 and includes an opening 10 for access to the driver's compartment 8, as Figure 7 shown in . Since the floor 9 is located at a relatively high level above the ground, the cab 5 includes steps 11 arranged on the side walls 7 for allowing the driver to climb up or down from the driver's co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com