Rapid assembling and disassembling die for mold sealing of grouting area of lower portion of assembling type prefabricated wall and using method

A prefabricated wall and assembly technology, applied in the direction of molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of easy grout leakage, difficult sealing of grouting area, and limited grouting time, so as to ensure verticality and even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

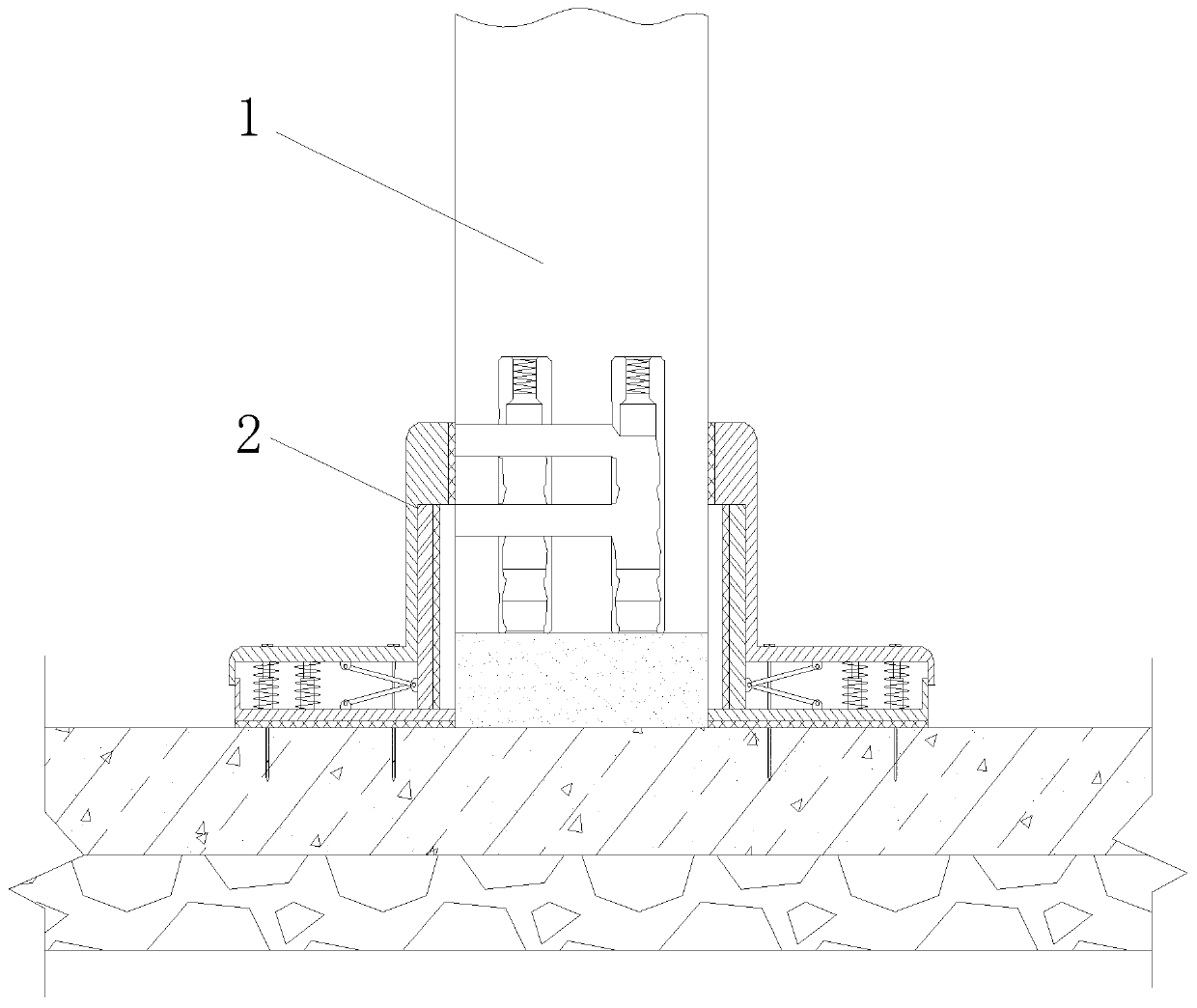

[0036] like Figure 1 to Figure 3 As shown, the sealing mold in the grouting area at the lower part of the prefabricated prefabricated wall is quickly assembled and disassembled.

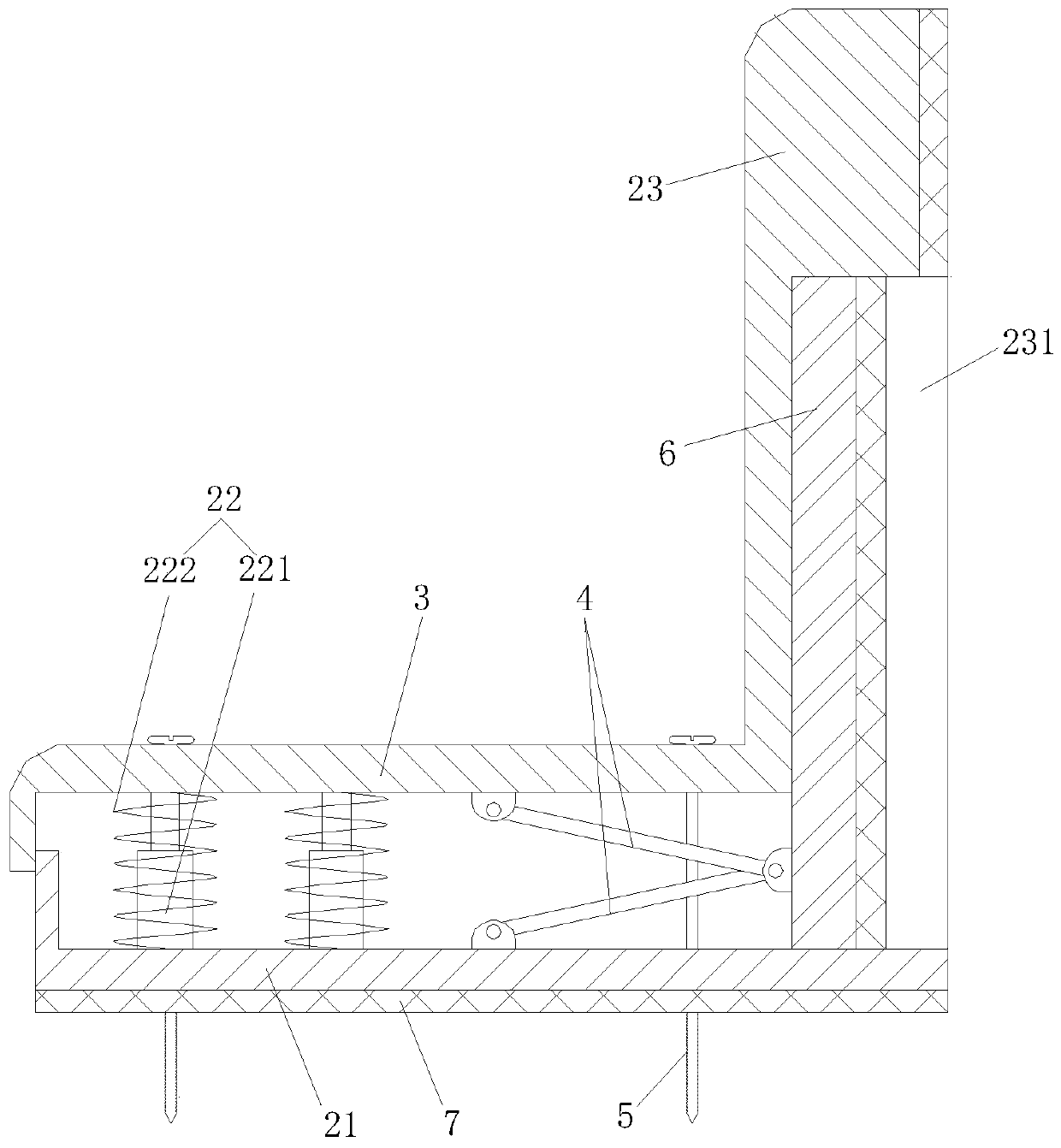

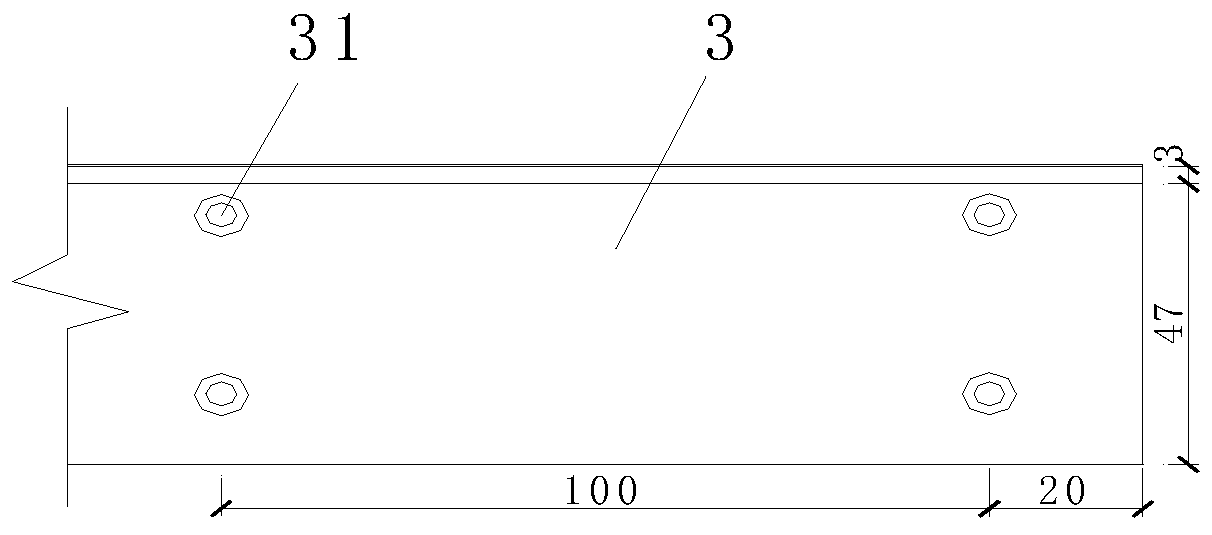

[0037] The L-shaped blocking assembly 2 includes a fixed seat 21 . The fixed seat 21 is provided with a first guide unit 22 . The first guide unit 22 includes a guide column 221 . The outer side of the guide column 221 is sleeved with a compression spring 222 . The end is fixedly connected to the fixed seat 21 , and the free end of the guide post 221 is fixedly connected to the cover plate 3 . When the cover plate 3 is moved downward by an external force, the pressing guide post 221 moves downward to a preset position. When the cover plate 3 is not subjected to external force, the cover plate 3 can be quickly reset to the initial state under the action of the compression spring 222 . A push unit is provided between the cover plate 3 and the fixed seat 21, and the push unit includes two symmetricall...

Embodiment 2

[0040] The difference from Example 1 is: as Figure 4 to Figure 5 As shown, the extrusion part 6 is provided with a second guide unit. The second guide unit includes a positioning plate 61 and a guide rod 62. The positioning plate 61 is located above the cover plate 3. 61 is fixedly connected, and a tension spring 63 is sleeved on the guide rod 62 on the outer side of the fitting portion 23. The elastic force of the tension spring 63 is smaller than that of the compression spring 222, and one end of the tension spring 63 is fixedly connected with the positioning plate 61, and the tension spring 63 is fixedly connected to the positioning plate 61. The other end of the extension spring 63 is fixedly connected to the fitting portion 23 . The extrusion member 6 is guided by the guide rod 62 , and the deflection of the extrusion member 6 is avoided by using the elastic force of the extension spring 63 less than the elastic force of the compression spring 222 .

Embodiment 3

[0042] The difference from Example 2 is: as Image 6 and Figure 8 As shown, a scraping groove 232 is opened in the fitting part 23 at the top of the installation groove 231, and a cleaning unit is arranged in the scraping groove 232. The cleaning unit includes a brush 8, a brush handle 9 and a return spring 10, and the brush 8 is fixedly connected to the One end of the brush handle 9, the end of the brush 8 away from the brush handle 9 is fixedly connected with the scraper 11, the other end of the brush handle 9 extends to the outside of the scraping groove 232, the return spring 10 is sleeved on the outside of the brush handle 9 and one end is It is fixedly connected with the brush handle 9 , and the other end of the return spring 10 is fixedly connected with the fitting portion 23 . After the mold is removed, use the downward movement of the brush handle 9 to clean the surface of the elastic sealing gasket 7 or the extrusion part 6 by the brush 8 and the scraper 11 in sequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com