Multifunctional machining device for precise metal structural parts

A technology for metal structural parts and processing devices, which is applied to metal processing equipment, metal processing mechanical parts, grinding/polishing safety devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

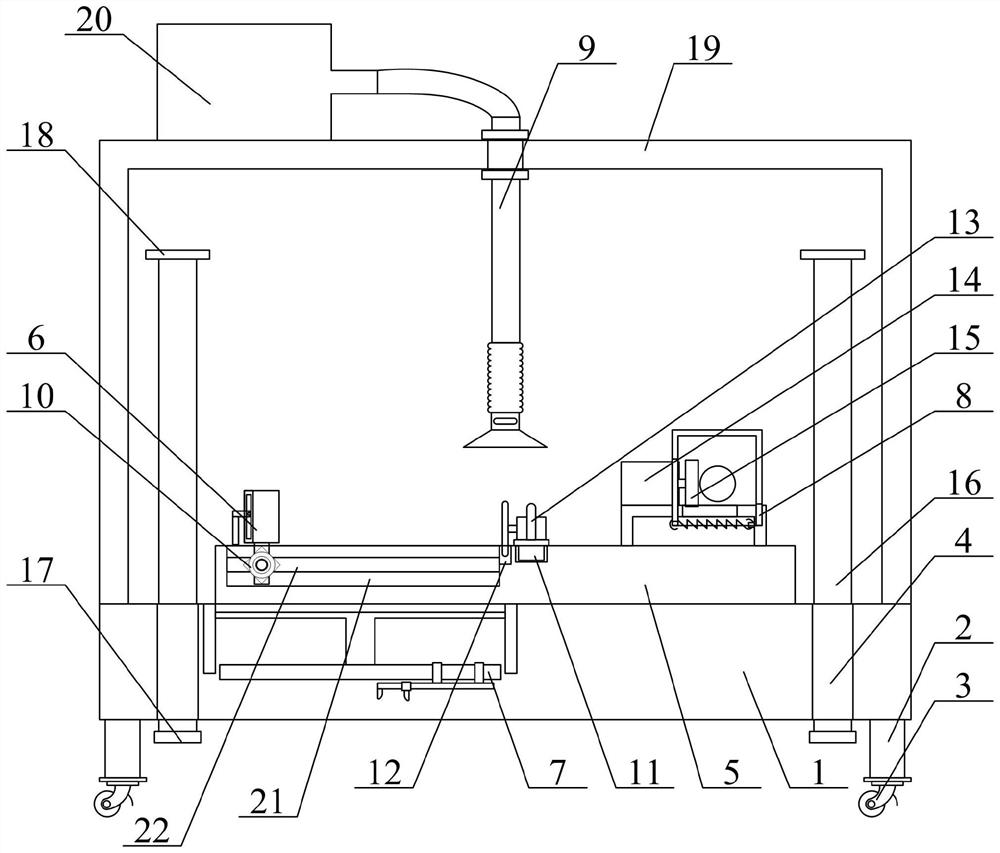

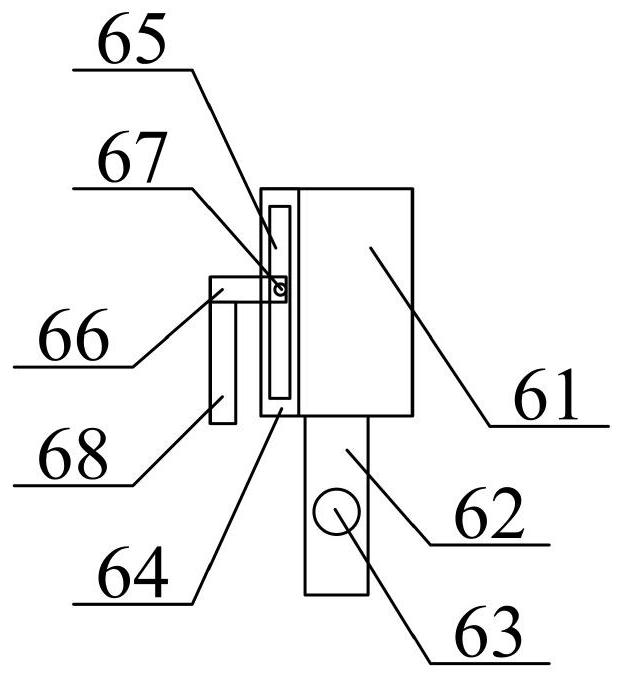

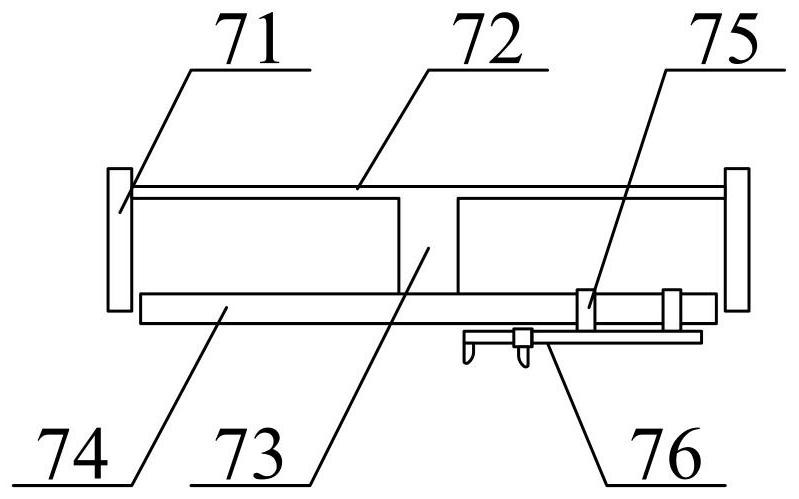

[0023] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, a multifunctional processing device for precision metal structural parts includes a support table 1, a support column 2, a movable brake wheel 3, a threaded hole 4, a processing table 5, a slidable support anti-shake block structure 6, and a rotatable Measuring positioning frame structure 7, slidable protective grinding seat structure 8, adjustable rotating dust cover structure 9, lock nut 10, sliding seat 11, cutting groove 12, first pulling rod 13, grinding motor 14, precision grinding wheel 15, Threaded column 16, base plate 17, first rotating rod 18, fixed cover 19, vacuum cleaner mechanism 20, first sliding groove 21 and sliding hole 22, the four corners of the lower end of the support platform 1 are respectively bolted with supporting columns 2; The lower ends of the support columns 2 are respectively bolt-connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com