Stripping mechanism for concrete mixer

A technology of concrete mixer truck and unloading mechanism, which is applied to unloading devices, cement mixing devices, clay preparation devices, etc., can solve the problem of easy blockage of the sliding pipe, avoid clumping and blockage, save construction material costs, reduce The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

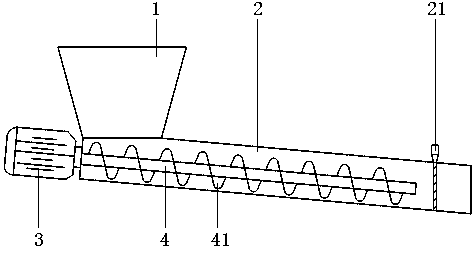

[0020] refer to figure 1 , the present invention is achieved in this way: a discharge mechanism for concrete mixer trucks, which includes a hopper 1 and a material slide pipe 2 inclined at the bottom of the hopper 1; 41 of the rotating shaft 4, one end of the rotating shaft 4 stretches out of the slide pipe 2 and is connected to the drive motor 3, and the slide pipe 2 is provided with a gate valve 21 at the tail end of the conveying direction.

[0021] refer to figure 1 As shown, in the present invention, the driving motor 3 is arranged on the outside of the front end of the material chute 2 in the conveying direction, and one end of the rotating shaft 4 is connected with the output shaft of the driving motor 3, and the other end of the rotating shaft 4 extends into the material chute 2 and is parallel to the shaft. Extending to the tail end of the delivery direction of the material slide pipe 2, the rotating shaft 4 is provided with a helical blade 41 on the outer circular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com