Glue rolling and paper coating device and packaging method for firework packaging line

A packaging line and glue rolling technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of easy blockage of the spray gun mouth, troublesome cleaning, and easy failure, and achieve low cost, uniform gluing, and glue leakage. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

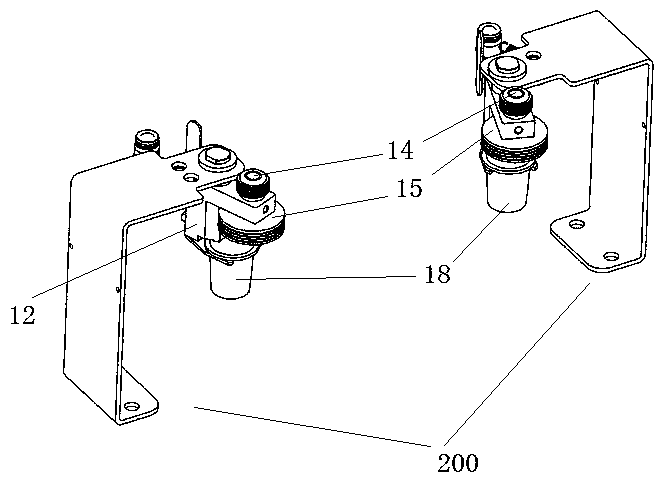

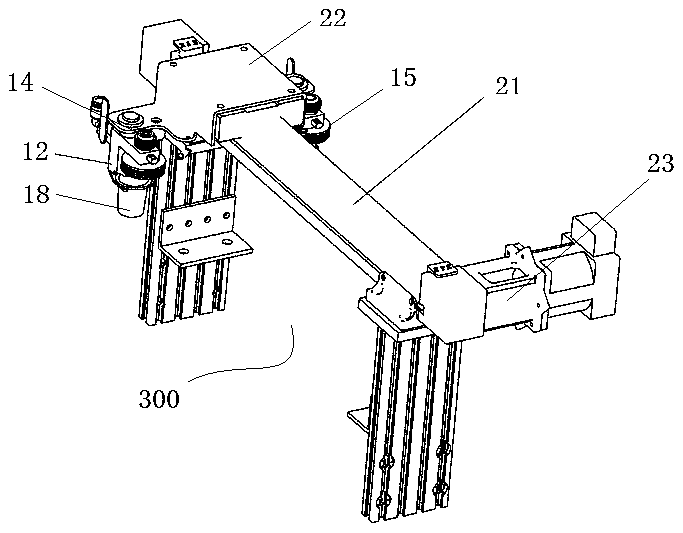

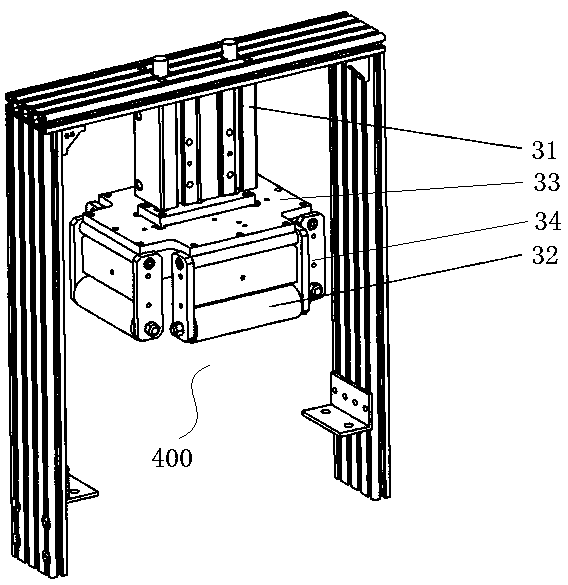

[0028] Attached below Figures 1 to 7 The preferred embodiment of the present invention is further described, including the production line 100, and also includes the X-direction rubber rolling device 200, the Y-direction rubber rolling device 300, the side paper rolling device 400, and the corner paper rolling device 500 arranged in sequence along the production line 100.

[0029] The X-direction rubber rolling device 200 and the Y-direction rubber rolling device 300 mainly include a rubber pipe 11, a glue stick 12, a shaft 13, a handle 14, and a rubber roller 15;

[0030] The rubber pipe 11 is connected to the glue stick 12, the glue stick 12 is fixed on the column on the side of the production line 100, the rubber roller 15 is set at the glue outlet 121 on the glue stick 12 through the shaft 13, the handle 14 and the top of the shaft 13 Fixed by threaded connection, the rubber roller 15 rotates around the axis 13;

[0031] It also includes a ball valve 17 and a pipe joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com