Air blowing device for head part of belt conveyor

An air purging device and belt conveyor technology, which is applied in the direction of conveyor objects, cleaning devices, transportation and packaging, etc., can solve the problem of increased workload of belt cleaners, inability to remove blast furnace slag, and difficult removal of blast furnace slag, etc. Problems, achieve the effect of reducing labor intensity, prolonging service life and reducing return materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

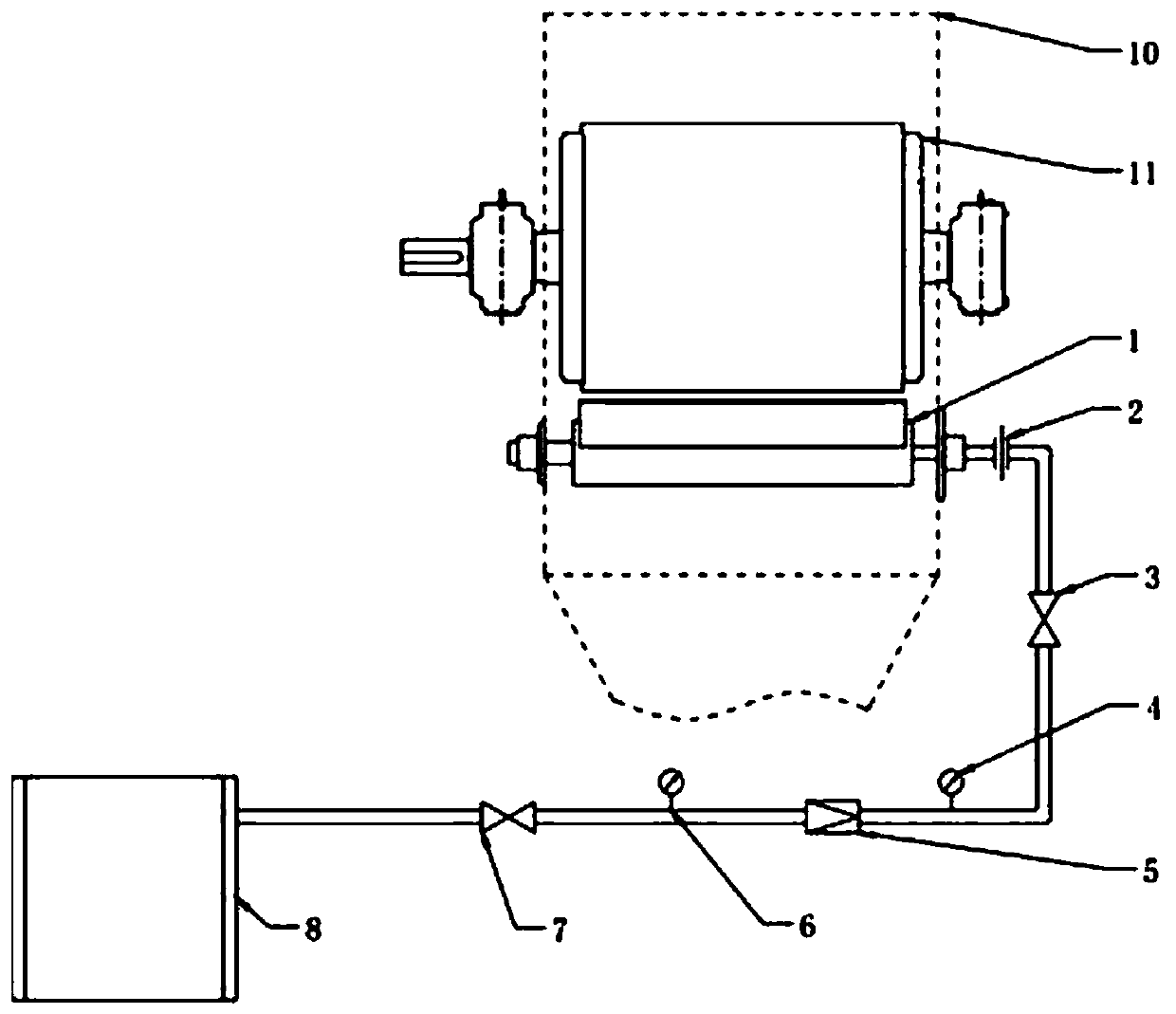

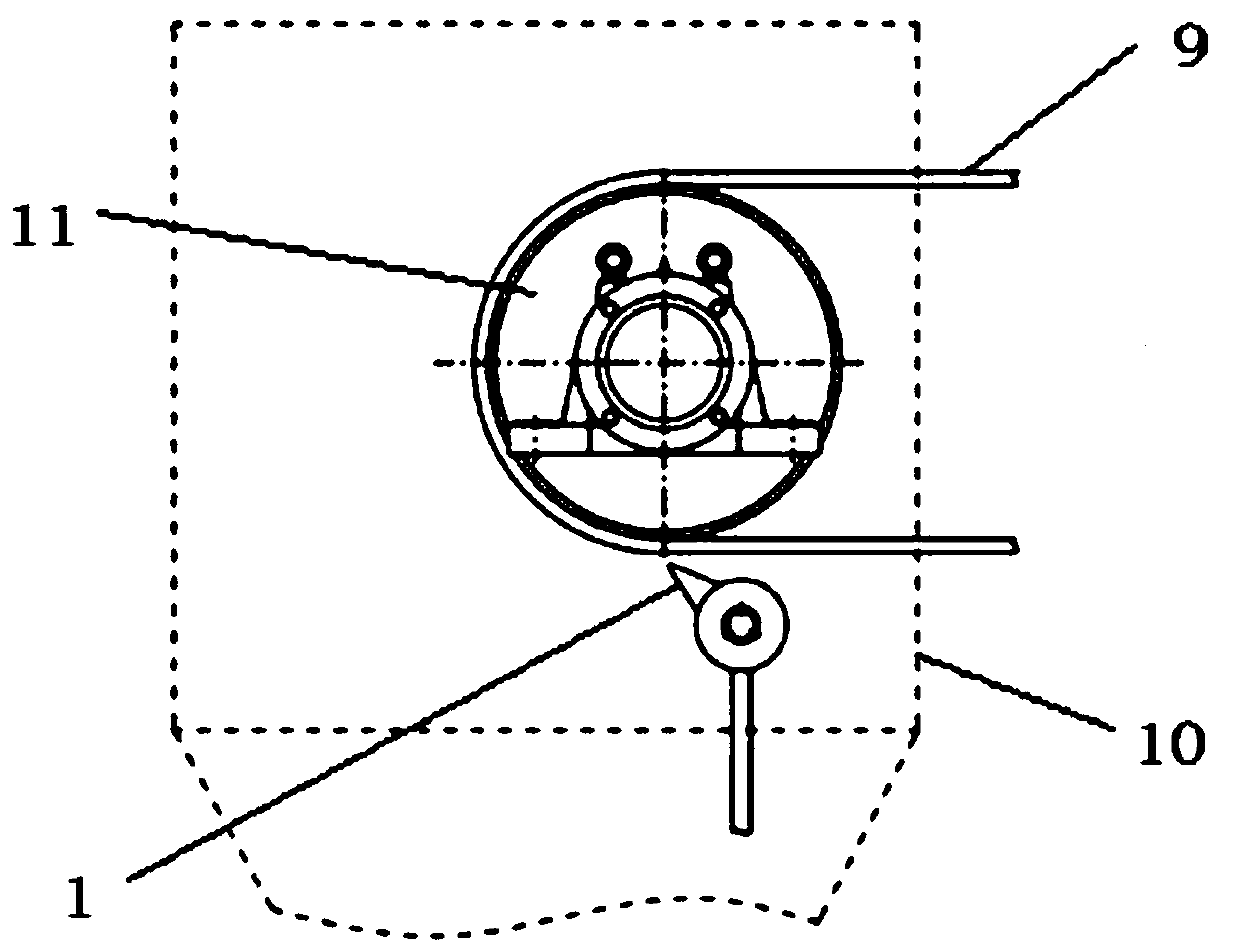

[0017] Such as figure 1 with figure 2 As shown, an air purging device at the head of a belt conveyor is used to be installed on a mineral powder vertical mill production line, which includes an air compressor 8 and a compressed air pipeline, and a first stop valve is sequentially arranged on the compressed air pipeline 7. The first pressure gauge 6, the pressure reducing valve 5, the second pressure gauge 4, the second shut-off valve 3, the movable joint 2 and the integrated nozzle 1, the integrated nozzle 1 is set on the mineral powder vertical mill through the movable base The inside of the belt conveyor head cover 10 of the production line is located below the belt conveyor head cylinder 11, and the movable base is fixed on the side plate of the belt conveyor head cover 10.

[0018] The air compressor 8 is a screw air compressor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com