Installation method of star wheel and silo at the head of sintering machine

A sintering machine and head technology, applied in the field of sintering machine head star wheel and silo installation, can solve the problems that the upper silo cannot be installed in advance, prolong the construction period, and the construction is difficult, so as to reduce the difficulty of installation and disassembly , improve safety and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

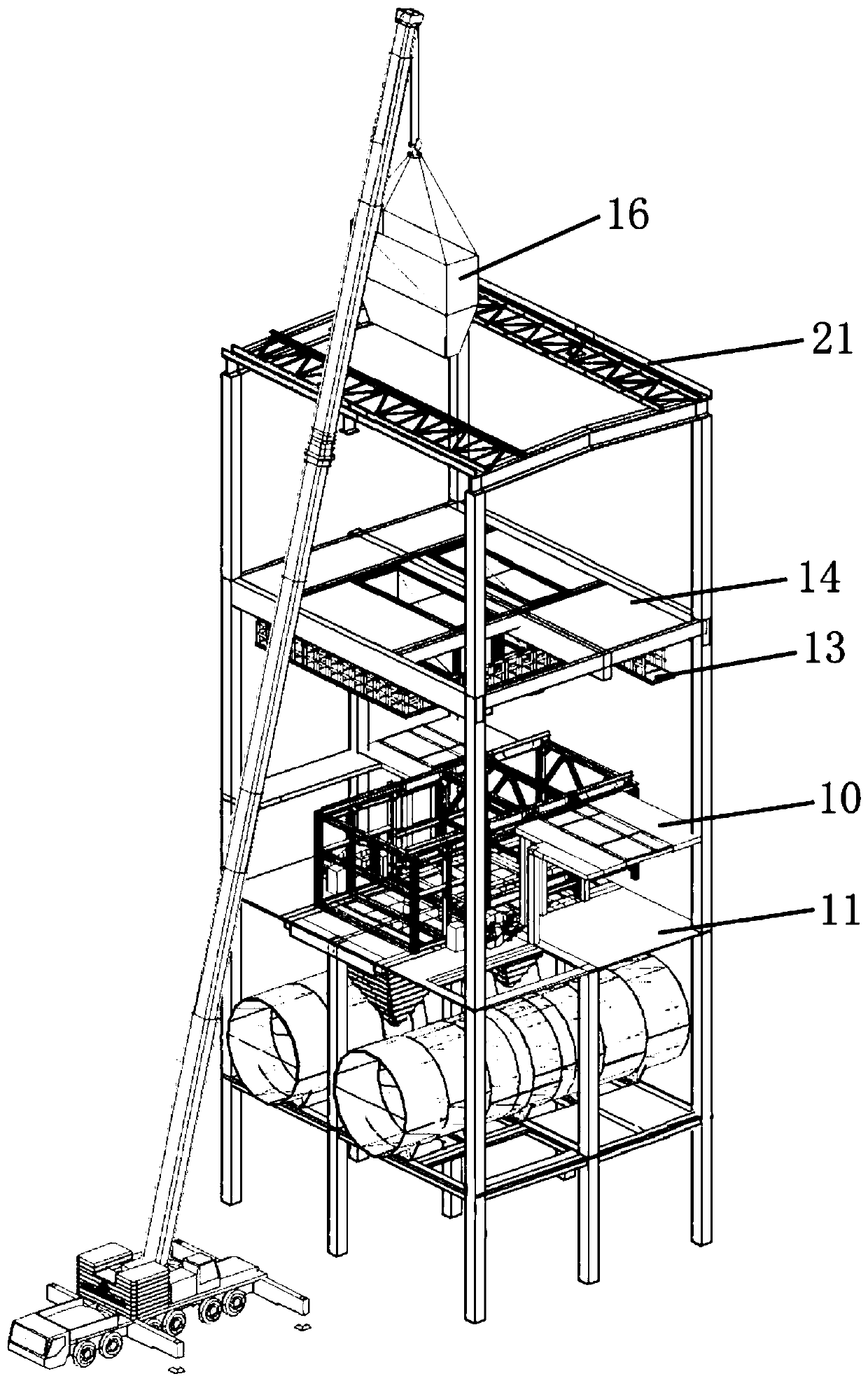

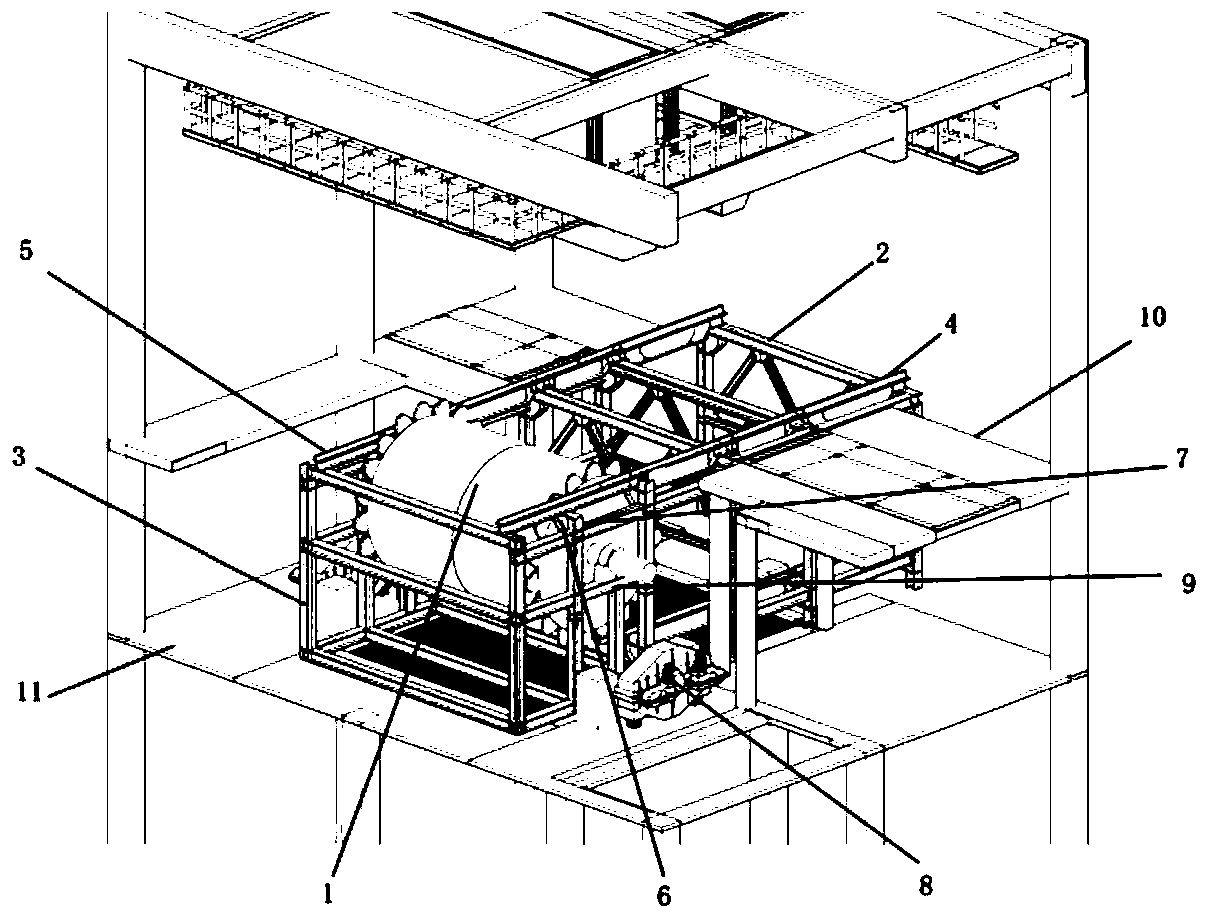

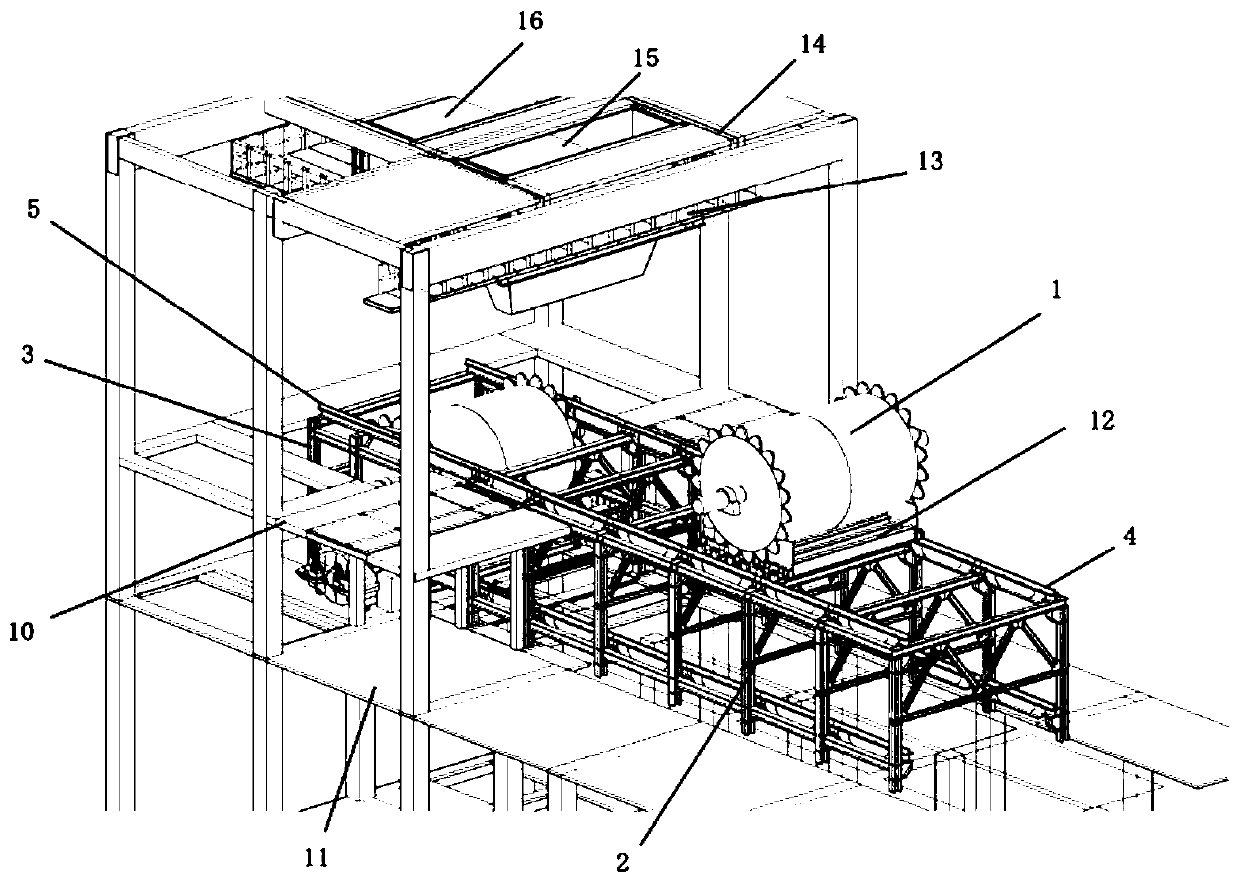

[0031] Such as Figure 1-6 A sintering machine head star wheel and silo installation method shown includes the following steps:

[0032] (1) Determine the construction position of the temporary hoisting beam and the hoisting chain: firstly use AutoCAD to make the head star wheel 1 of the sintering machine, the skeleton of the sintering machine, the concrete frame structure of the sintering chamber, the flexible transmission de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com