Construction method and equipment for a new type of track orthogonal prefabricated in-site zigzag transfer beam

A construction method and technology of construction equipment are applied in the field of construction method and construction equipment of a new type of rail-orthogonal prefabricated line-shaped transfer beam in the field, which can solve the problem of high cost of prefabrication yard, high cost of tire-type beam moving machine, large running, high cost, etc. Turning to space and other issues to achieve the effect of reducing the occupied area, improving the site utilization rate, and economic dominance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

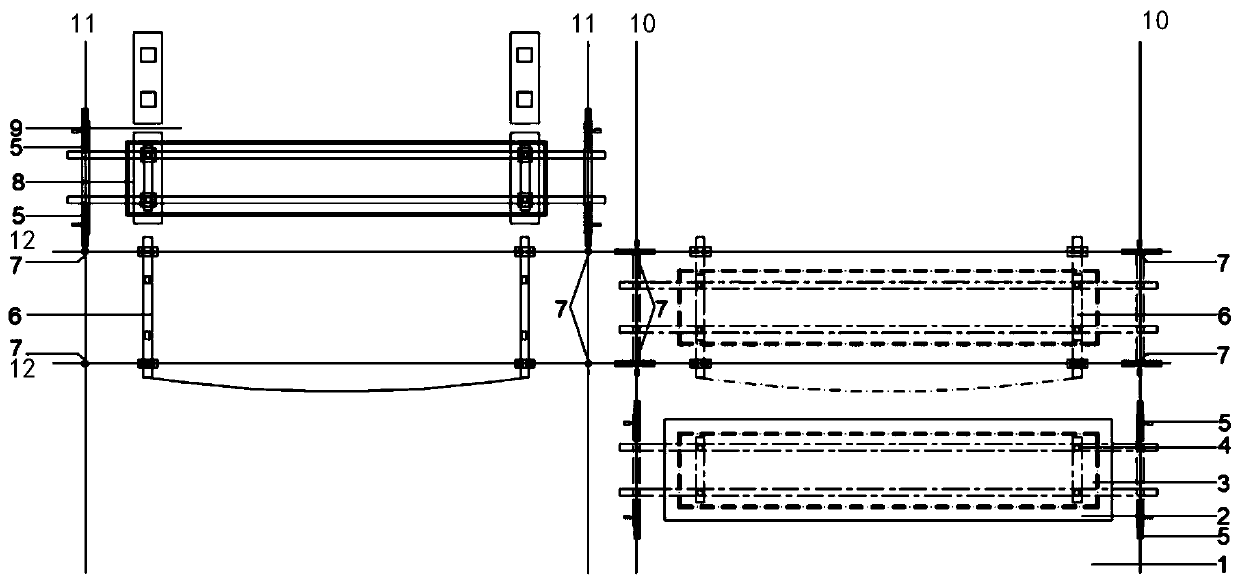

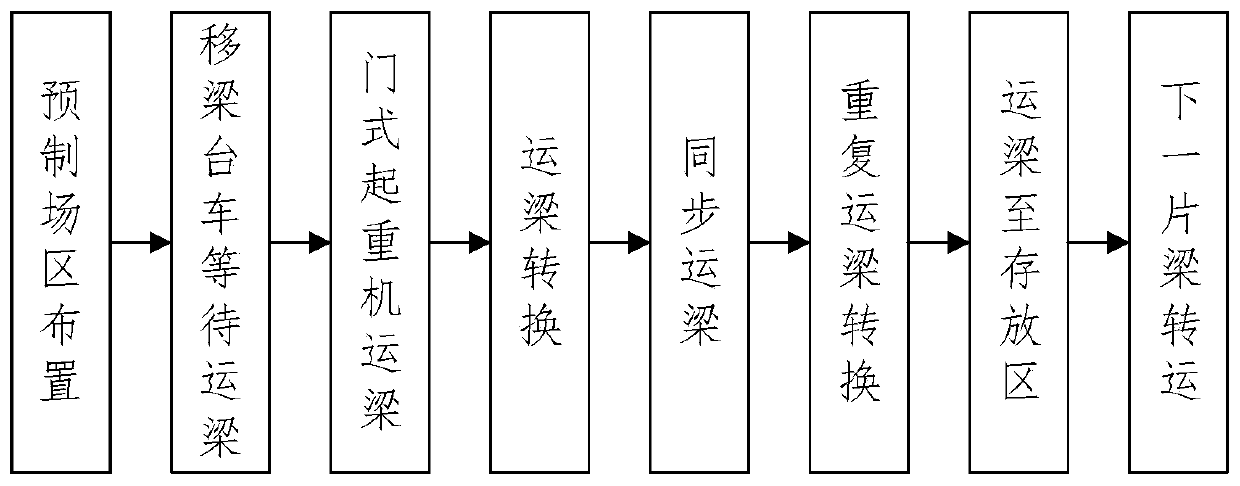

[0043] Such as figure 1As shown, this embodiment provides a new type of construction method for track-orthogonal prefabricated line-shaped transfer beams in the field. The construction method is carried out using construction equipment, and the construction equipment includes a beam-making platform 2 arranged in the transfer area 1, a set The beam storage stand 8 in the storage area 9, the beam making track 10 arranged on both sides of the beam making stand 2 perpendicular to the length direction of the beam making stand 2, and the beam making track 10 arranged on the two sides of the beam making stand 2 perpendicular to the length direction of the beam storage stand 8 The beam storage track 11 on both sides of the beam platform 8, the orthogonal track 12 orthogonally connected to the beam making track 10 and the beam storage track 11, the gantry crane 4, the gantry crane steering device 5, and the orthogonal track steering device 7 , and a beam-moving trolley 6, the gantry cr...

Embodiment 2

[0055] On the basis of Embodiment 1, the beam-moving trolley 6 includes a front trolley and a back trolley whose spacing can be adjusted along the extending direction of the orthogonal track 12, and the step b also includes: adjusting the front trolley and the back trolley according to the length of the transported prefabricated beam The distance of the car in the background. The beam moving trolley can adjust the spacing according to the size of the prefabricated beams by setting the front truck and the back truck, which improves the flexibility of beam transportation.

Embodiment 3

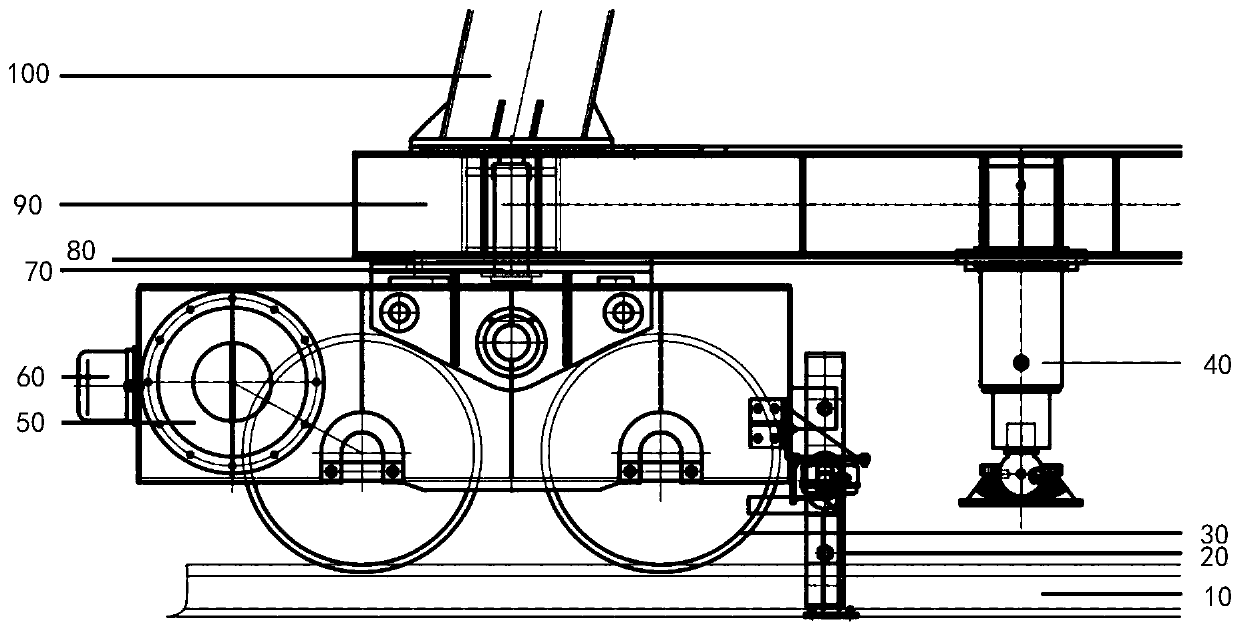

[0057] On the basis of Example 1, such as figure 2 As shown, the gantry crane is connected to the rails through outriggers 100, and the spacing of the orthogonal rails 12 is the same as that of the outriggers 100 on one side of the steering device 5 of the gantry crane. The supporting legs 100 of the gantry crane 4 are connected to the track through the traveling beam 90 and the traveling gear 30. The bottom of the leg 100 of the gantry crane 4, the traveling gear 30 is driven by the traveling motor 50 to move along the track, and the steering device 5 of the gantry crane includes a walking beam 90 connected to the track for jacking up the The jack 40 of walking beam 90. One side of the travel gear 30 is provided with an anti-collision device 60 . The traveling gear 30 is controllably locked to the beam making track 10 through the locking track device 20 . In this embodiment, by setting the traveling gear, the gantry crane can travel along the track. At the same time, by s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com