Double-layer combined casing with girth weld and assembling method thereof

A combined casing and assembly method technology, which is applied in the direction of casing, drill pipe, earthwork drilling and production, etc., can solve the problems that there is no double-layer combined casing assembly method, the oil production project cannot be carried out, and the inner layer casing is damaged, etc., to achieve Improve the integrity and connection strength and rigidity, improve the quality of fixing, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

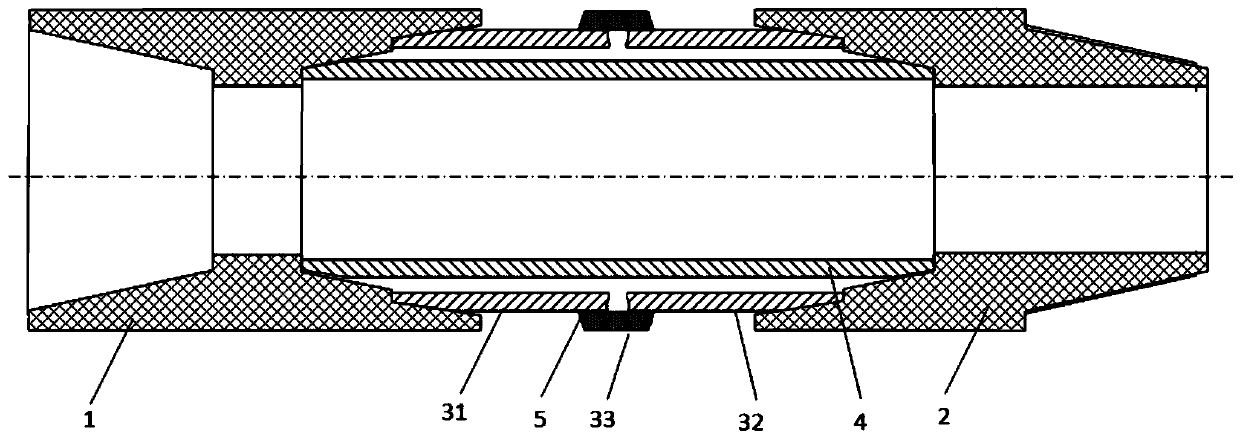

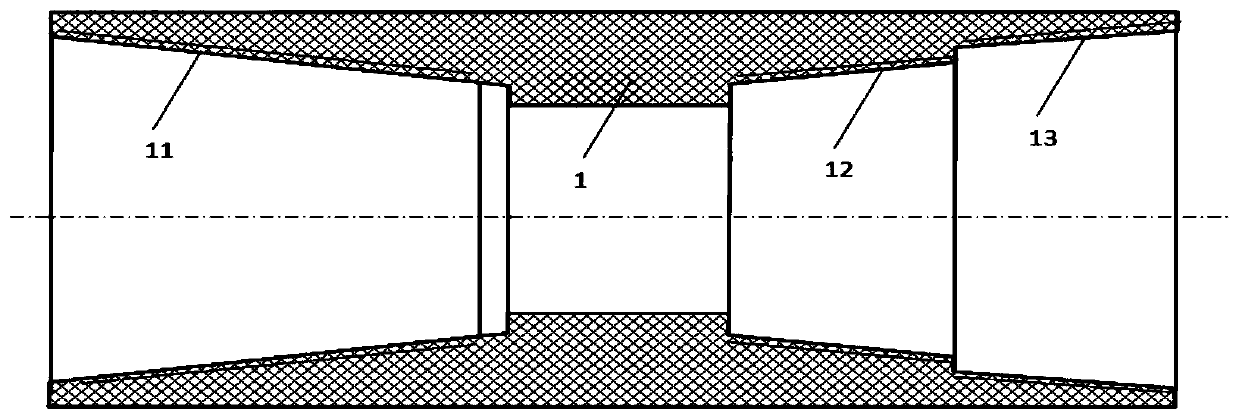

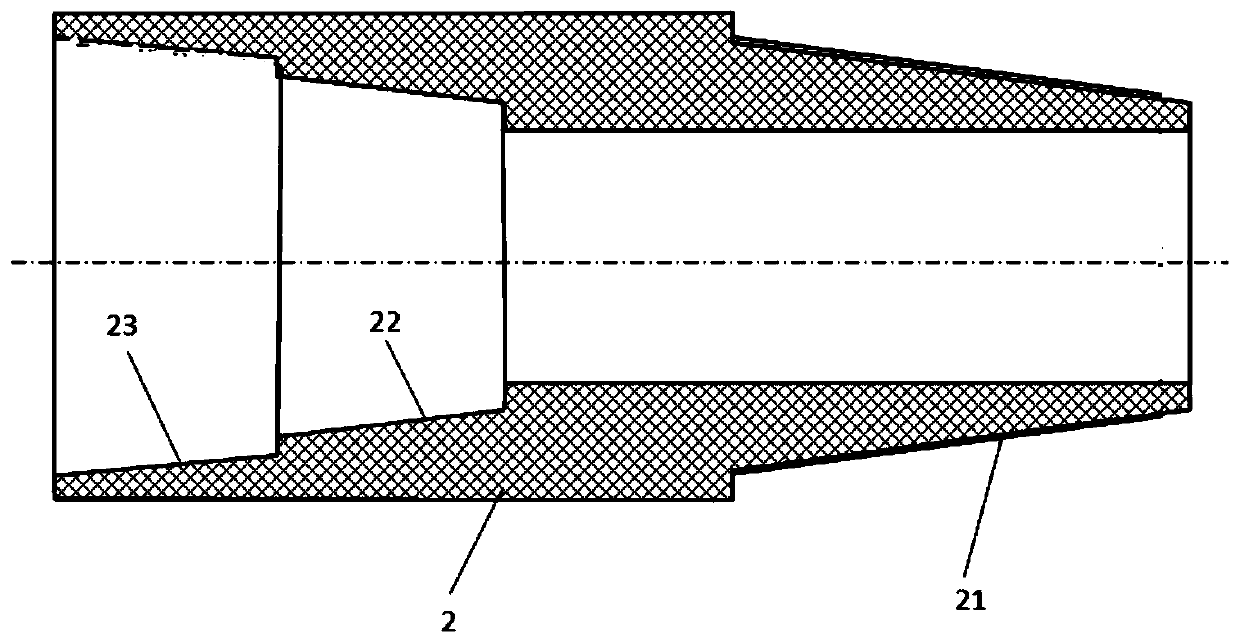

[0027] Such as figure 1 As shown, a double-layer combined casing with a girth weld includes an internally threaded collar joint 1, an externally threaded collar joint 2, an outer layer casing 3, an inner layer casing 4 and a connecting ring, wherein the outer layer The casing 3 has three sections, including an internal thread collar joint section 31, an external thread collar joint section 32 and a connecting ring 33 between the two sections; the internal thread collar joint section 31 and the external thread joint section of the outer casing 3 The collar joint section 32 is threadedly connected with the inner thread collar joint 1 and the outer thread collar joint 2 respectively, and the two ends of the inner casing 4 are respectively connected with the inner thread collar joint 1 and the outer thread collar joint 2, and the inner thread collar joint 1 and the outer thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com