Fast joint for high pressure variable frequency water pump in mine environment

A frequency conversion water pump, medium and high pressure technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems of poor sealing, difficult to achieve fast alignment connection, not smooth and convenient connection, etc., to achieve the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

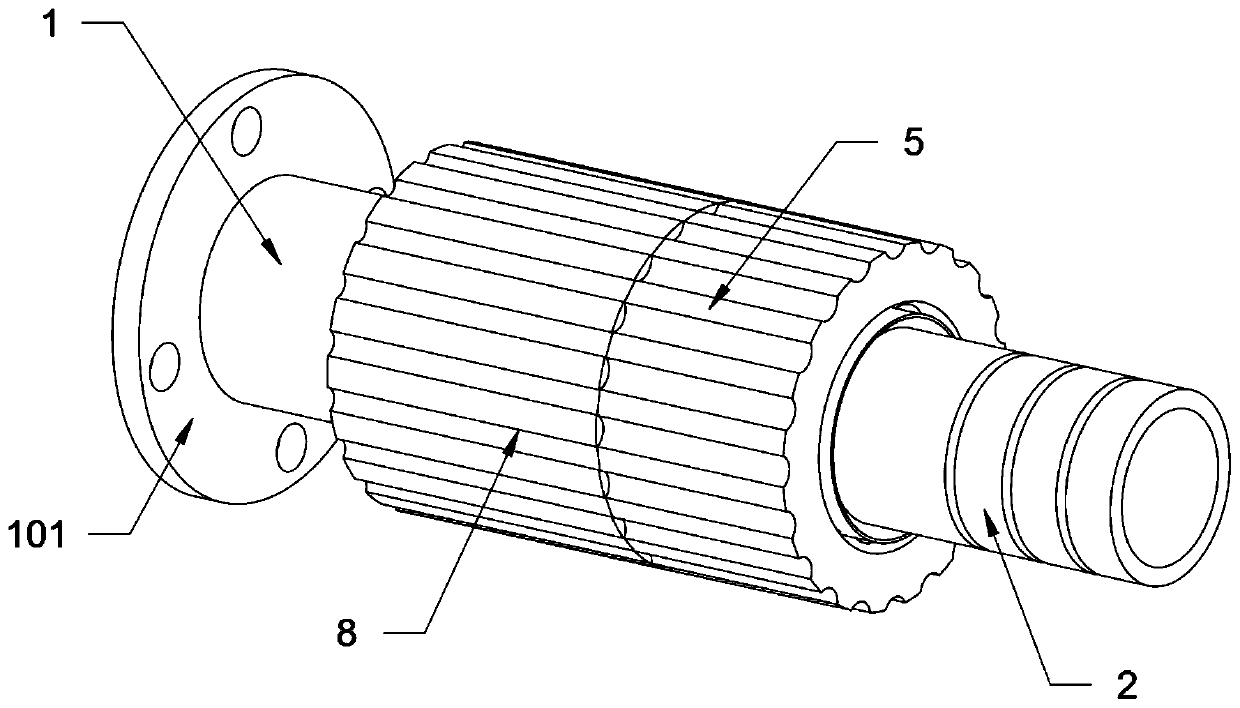

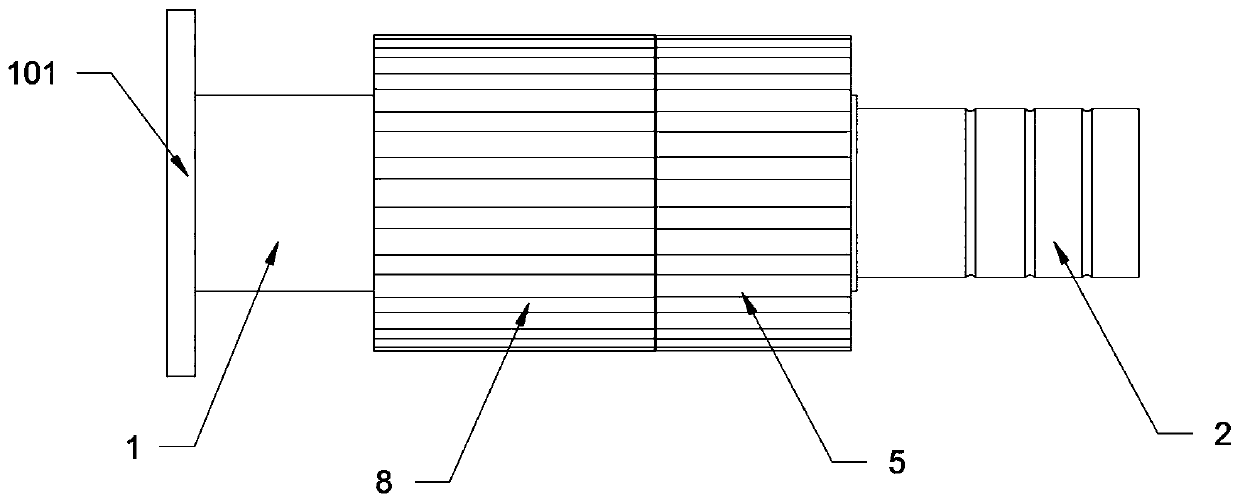

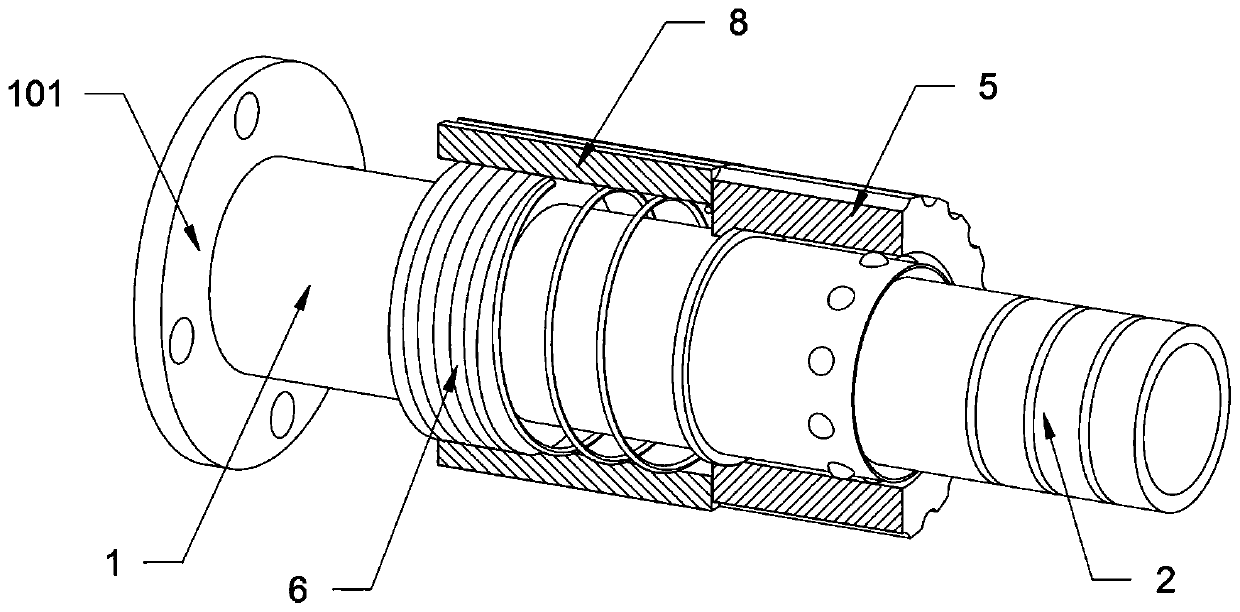

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The invention provides a quick joint for a high-voltage frequency conversion water pump in a mine environment, including a joint seat 1, a fixed seat 101, a tapered groove A102, a joint body 2, a card slot A201, a card slot B202, a card bead 3, a retaining ring 4, and a card sleeve 5 , stud 6, spring 7, limit nut 8, annular stopper 9, tapered groove C901 and rubber pad 10; the joint seat 1 is a cylindrical tubular structure, and the rear end surface of the joint seat 1 is welded with an annular The fixed seat 101, and the front side of the outer wall of the joint seat 1 is provided with ten snap beads 3 for matching with the slot A201 in an annular array; the joint main body 2 is a cylindrical tubular structure, and the joint main body 2 There is a card slot A201 matching the card bead 3 at the front side of the outer wall; a stop ring 4 is welded on the outer wall of the joint seat 1, and a ferrule 5 is sleeved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com