Integrated harmless treatment process for imidazole three wastes from industrial production

A technology for harmless treatment and production of imidazole, which is used in incinerators, greenhouse gas reduction, combustion methods, etc., can solve the problem of reducing the sufficiency of gasification waste liquid and malodorous waste gas, unable to ensure full mixing of organic matter, and weakening exhaust gas purification. and other problems, to avoid insufficient air, avoid unclean purification, and improve the effect of thoroughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

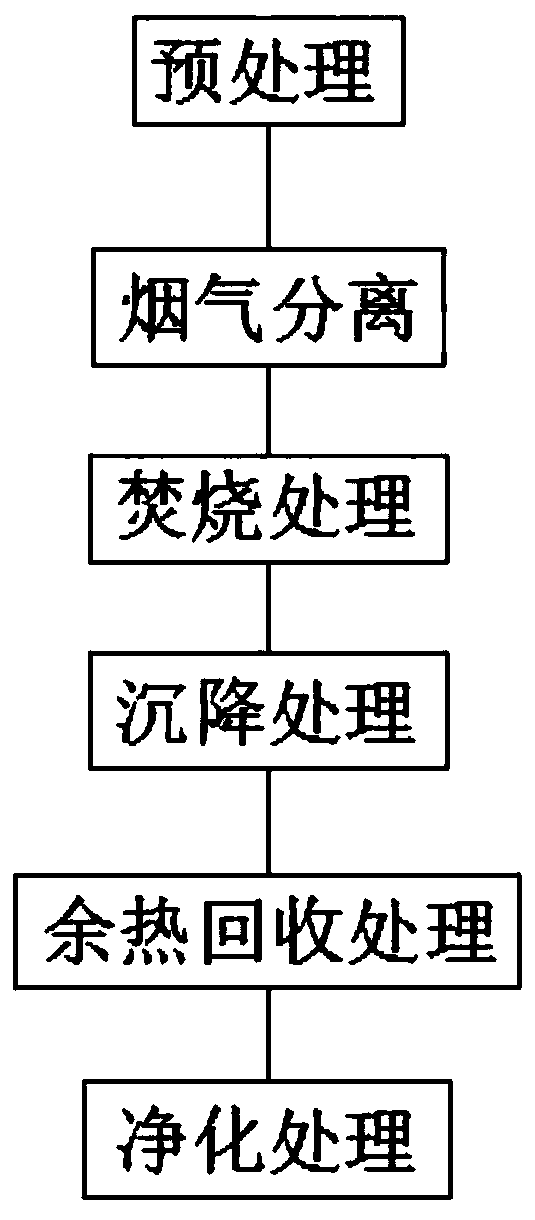

[0036] An integrated harmless treatment process for industrial production of imidazole and three wastes, the treatment steps are as follows:

[0037] a.: Firstly, the waste liquid and high-temperature flue gas are input into the pretreatment chamber and the waste liquid is atomized, and the waste residue is transported to the bottom of the pretreatment chamber, and the inorganic salts in it are precipitated into crystal particles and settle to the bottom of the pretreatment chamber;

[0038] b. After step a is completed, use a cyclone separator to separate the inorganic salt particles from the flue gas produced in the pretreatment chamber;

[0039] c. After step b is completed, the pretreated gasification waste liquid and malodorous waste gas are sent to the incineration device for incineration, and the organic matter and harmful substances in it are completely decomposed into small molecular harmless substances;

[0040] d. After step c is completed, the salt in the molten st...

Embodiment 2

[0045] An integrated harmless treatment process for industrial production of imidazole and three wastes, the treatment steps are as follows:

[0046] a.: Firstly, the waste liquid and high-temperature flue gas are input into the pretreatment chamber and the waste liquid is atomized, and the waste residue is transported to the bottom of the pretreatment chamber, and the inorganic salts in it are precipitated into crystal particles and settle to the bottom of the pretreatment chamber;

[0047] b. After step a is completed, use a cyclone separator to separate the inorganic salt particles from the flue gas produced in the pretreatment chamber;

[0048] c. After step b is completed, the pretreated gasification waste liquid and malodorous waste gas are sent to the incineration device for incineration, and the organic matter and harmful substances in it are completely decomposed into small molecular harmless substances;

[0049] d. After step c is completed, the salt in the molten st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com