CFRP laminate delamination failure behavior prediction method based on novel cohesion constitutive relation

A constitutive relationship and prediction method technology, applied in the direction of applying stable tension/compression to test the strength of materials, analyzing materials, measuring devices, etc., can solve the problems of damage expansion design, lack of physical basis for assumptions, and no clear calculation methods, etc. Achieve the effects of reducing test costs, good accuracy and applicability, and shortening the workload of experimental testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with embodiment the present invention is described in further detail:

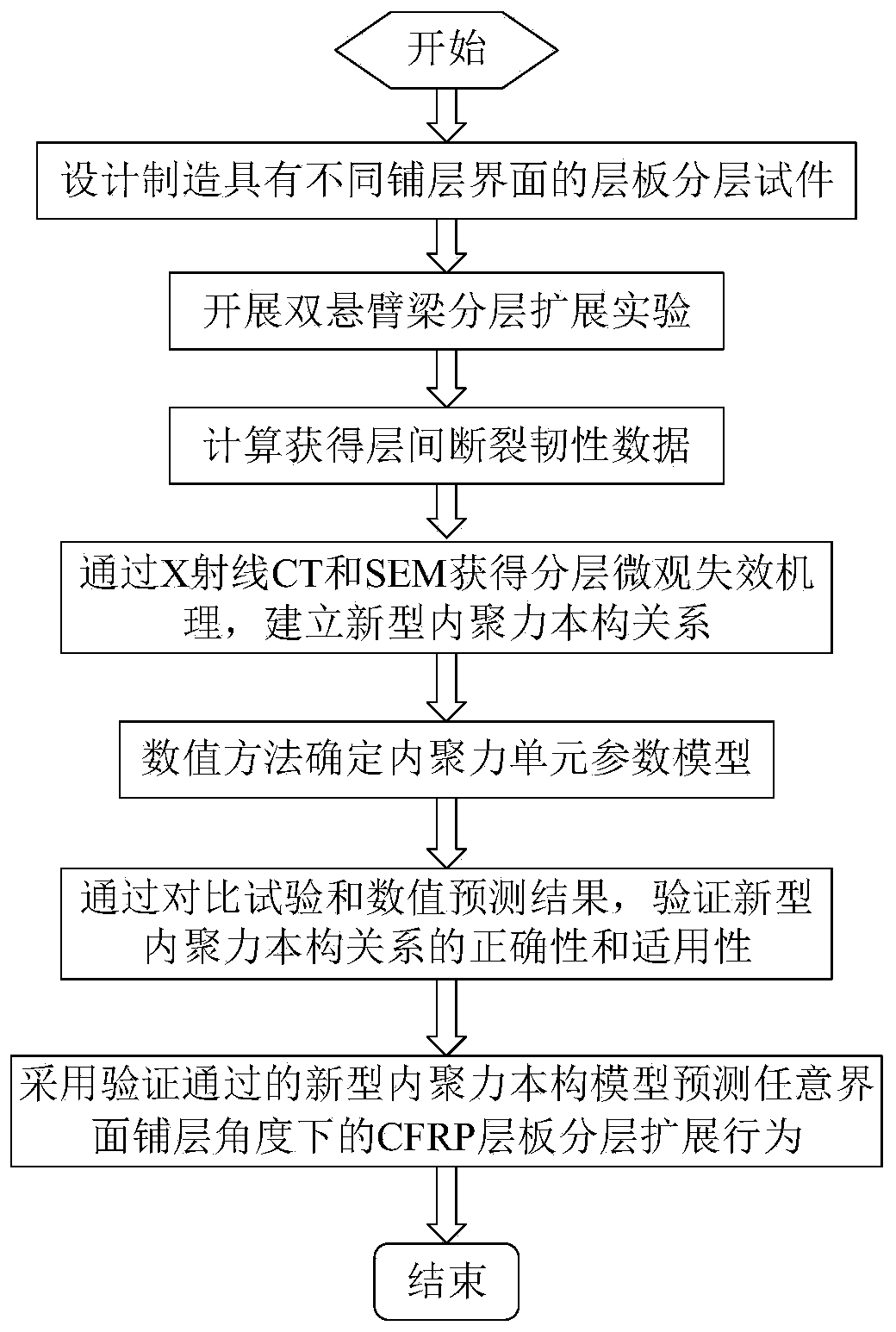

[0042] The specific implementation steps of a method for predicting the delamination failure behavior of CFRP laminates based on the new cohesive force constitutive relation of the present invention are as follows:

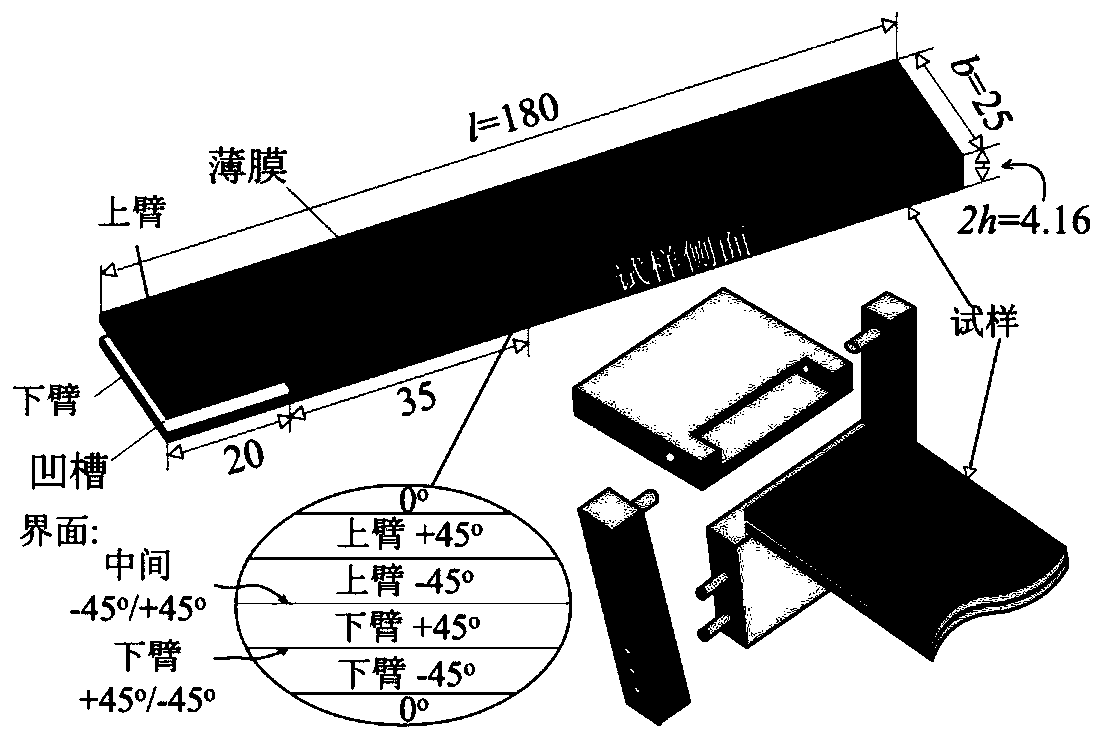

[0043] Step 1: Design and manufacture CFRP laminate delamination specimens with 0° / 5°, 45° / -45° and 90° / 90° according to ASTM D5528-13 standard. The sample is made of unidirectional prepreg of T700 / QY9511 carbon fiber / bismaleimide resin system, and the layup sequence is 0 16 / / (+5 / -5 / 0 6 ) S , (+45 / -45 / 0 6 ) S / / (-45 / +45 / 0 6 ) S and (90 / 0 / 90 / 0 5 ) S / / (90 / 0 / 90 / 0 5 ) S . The symbol / / indicates where the preformed cracks introduced during the manufacturing process are located. The size of the cut prepreg is 385mm×370mm. In the process of laying the prepreg, a layer of polytetrafluoroethylene layer with a thickness of 25 μm and a length of 35 mm is pre-lai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com