Experimental test device based on true crack state and test method thereof

A technology of experimental testing and real state, which is applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of difficult sampling of deep cracks, difficult testing, large testing errors, etc., to facilitate timely processing, increase reliability, The effect of increasing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

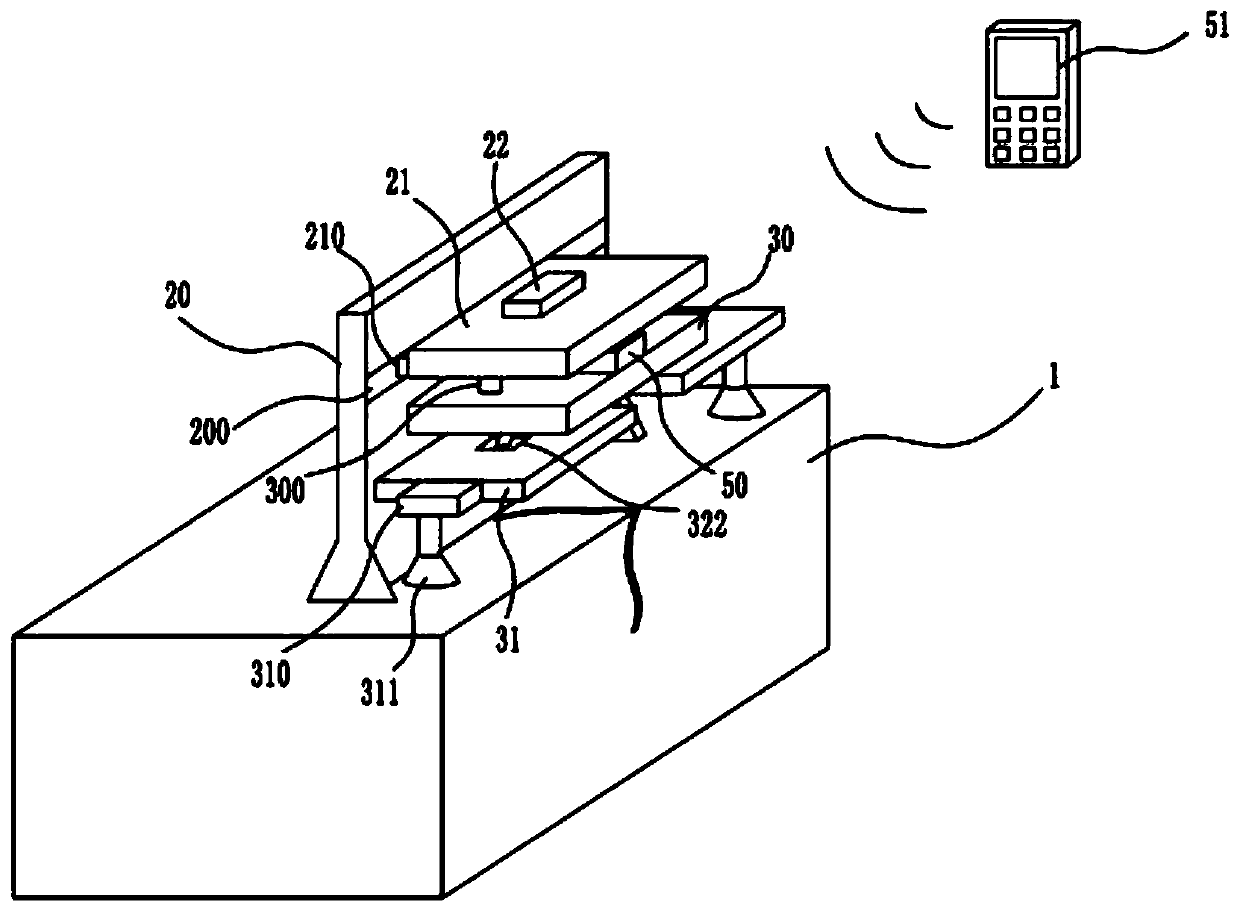

[0033] Example: such as figure 1 As shown, a test device based on the real state of cracks mainly includes a concrete block 1, a position adjustment element 2, a fixed element 3, a crack test element 4, an intelligent control element 5, and a power supply device; crack;

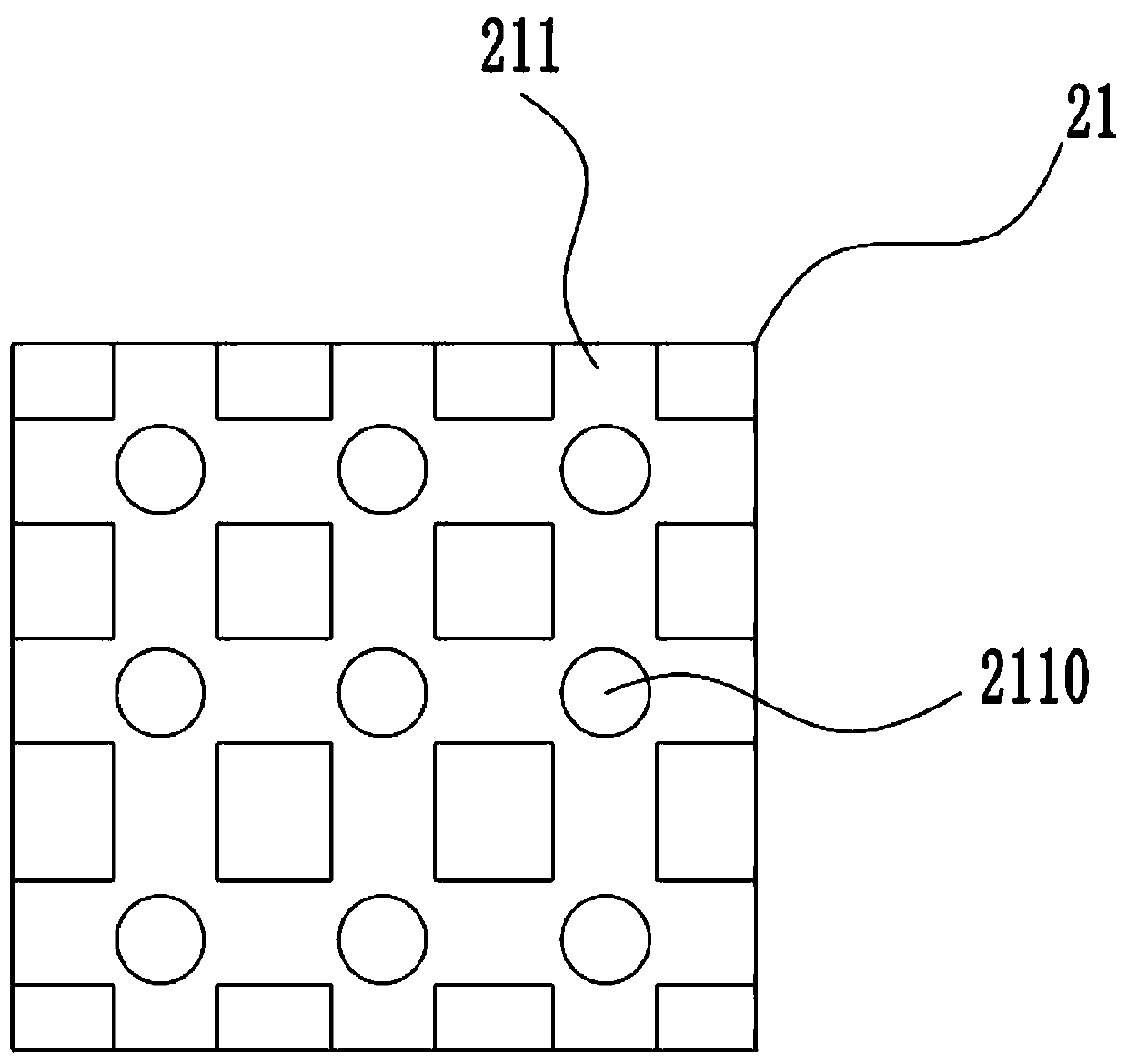

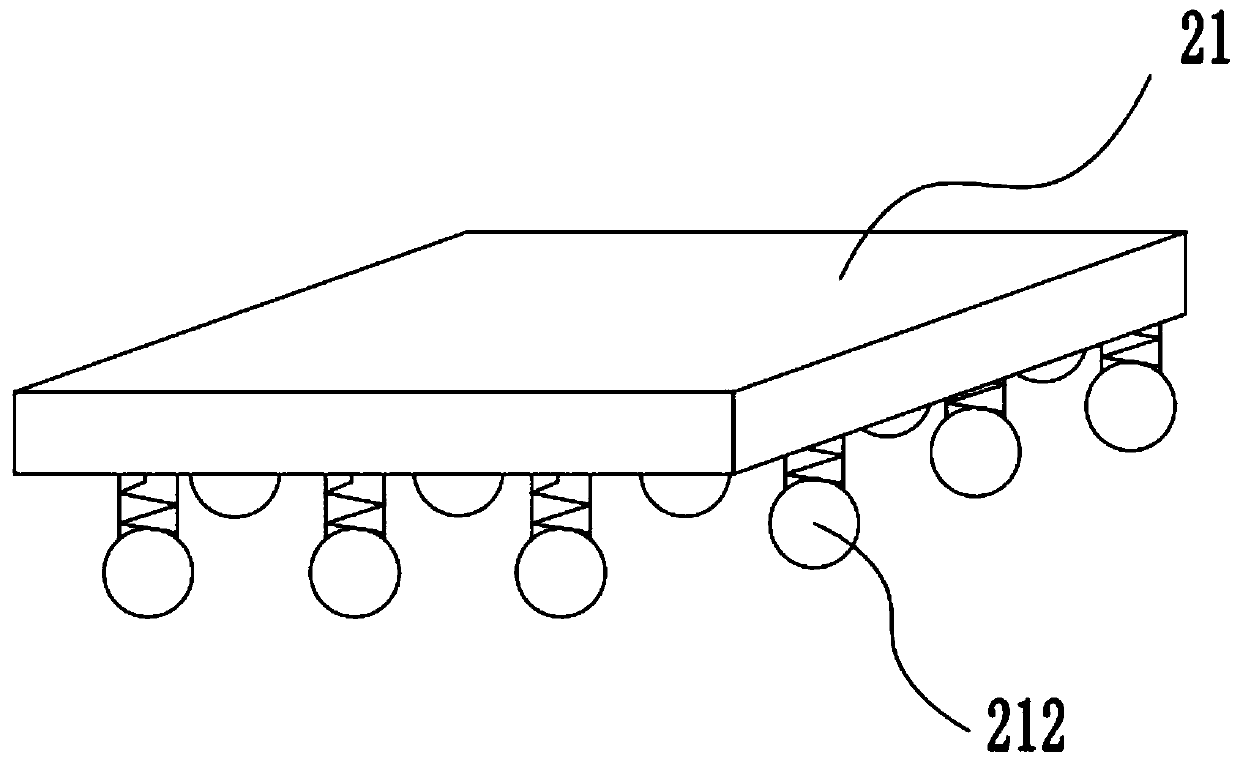

[0034] Such as figure 2 As shown, the position adjustment element 2 includes a mounting vertical plate 20 fixed on the concrete block 1 with a sliding groove 200 on the side along the horizontal direction, a chute moving plate 21 whose side wall is connected to the sliding groove 200 through a sliding block 210, and a driving sliding The drive motor one 22 that block 210 moves in slide groove 200, the bottom side of chute moving plate 21 is provided with the mesh groove 211 that is made of vertical groove and horizontal groove, vertical groove and horizontal groove intersect on mesh groove 211 There is a clamping hole 2110 at the bottom of the sliding column 300, and a sliding ball 301 is provided at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com