Multi-objective optimization method for injection molding parameters

A multi-objective optimization and multi-objective decision-making technology, applied in multi-objective optimization, design optimization/simulation, genetic rules, etc., can solve problems such as inability to obtain relevant model parameters, failure to consider expected molding results, and time-consuming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

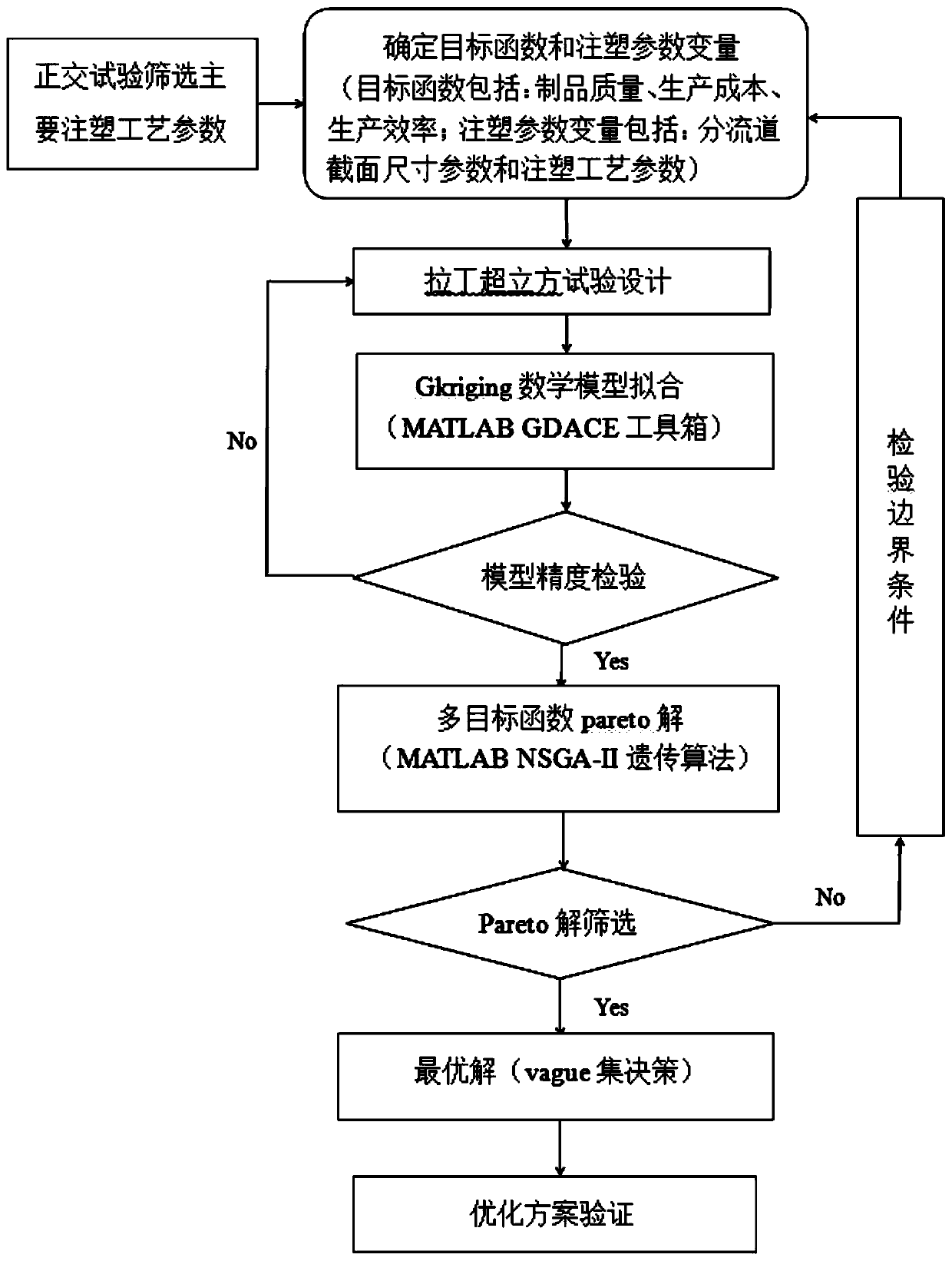

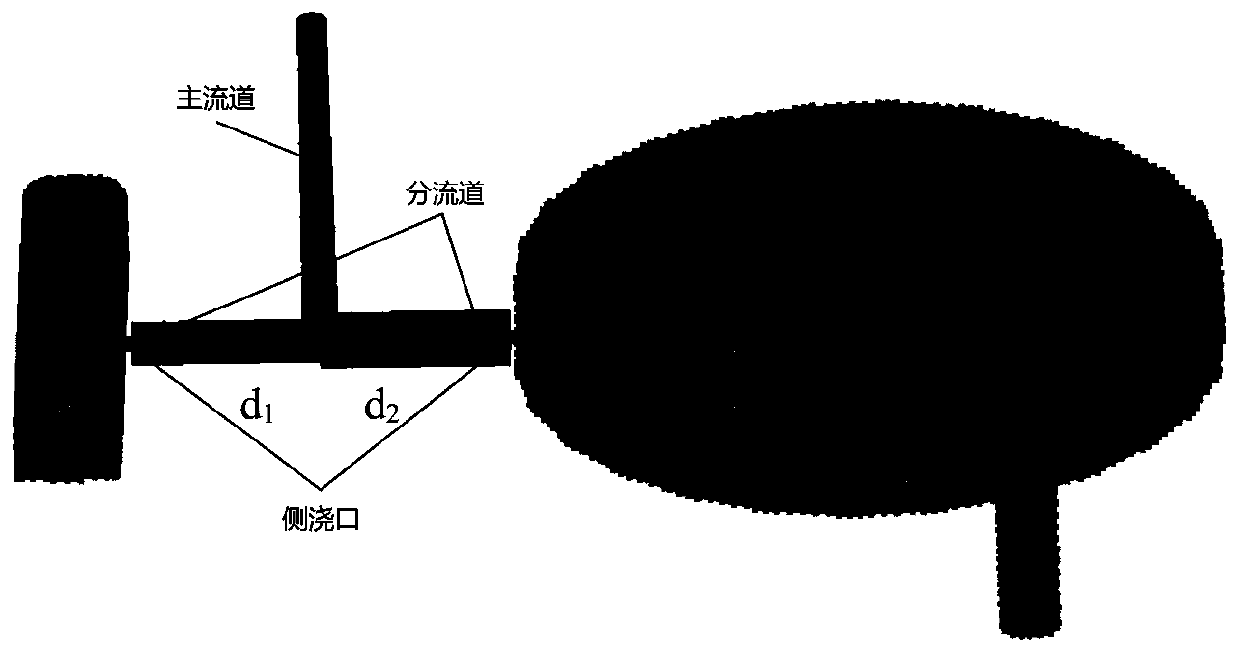

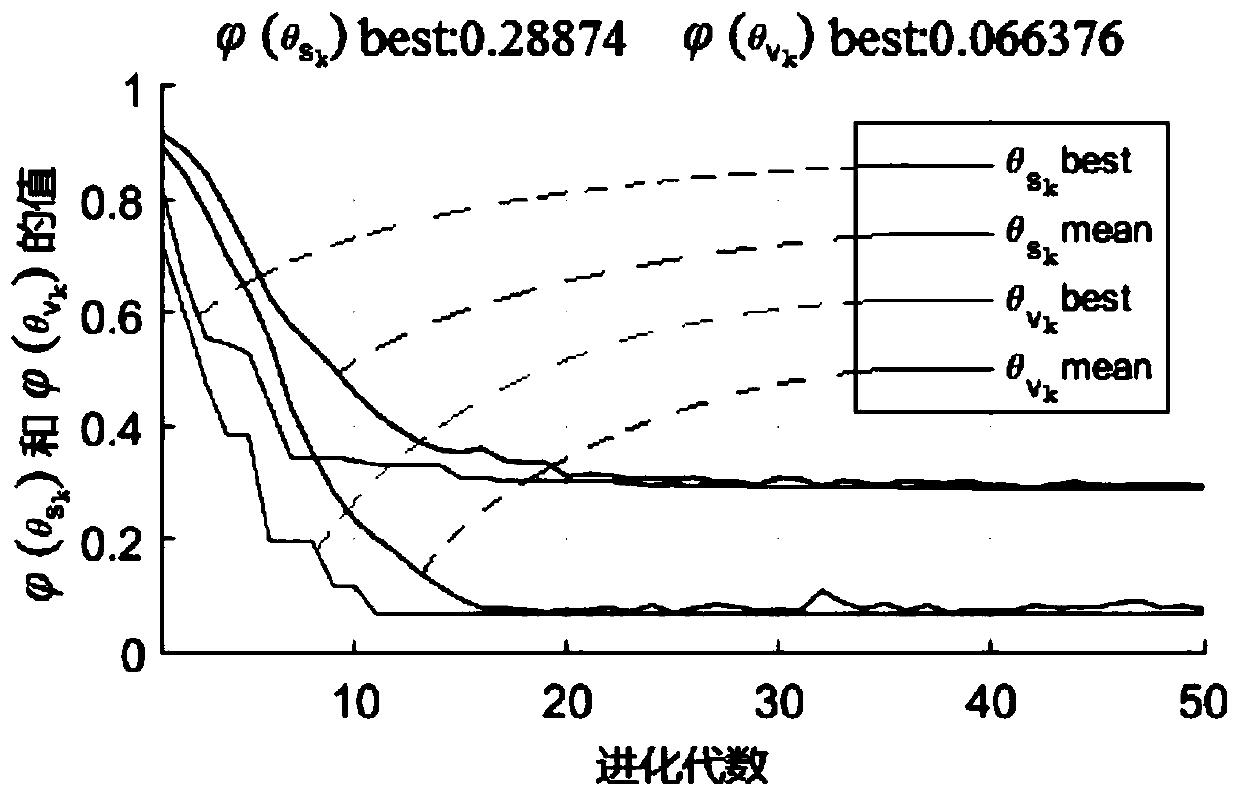

[0064] The multi-objective optimization method of injection molding parameters is based on the improved Kriging agent model (Gkriging), non-dominated sorting genetic algorithm (NSGA-Ⅱ) and fuzzy decision-making of vague set (Gkriging-NSGA-vague) strategy to deal with multi-objective optimization design. In the mathematical model of multi-objective optimization design of injection molding parameters, the size parameters of the injection mold runner section and the injection molding process parameters are selected as the decision variables to be optimized, and the maximum volume shrinkage of the product, the total volume of the runner and the molding cycle are respectively used as the product quality, For the evaluation index of production cost and production efficiency, the traditional Kriging agent model is improved by using GA genetic algorithm, and the optimal initial value of the relevant model parameters is obtained; the Gkriging model of each target and design variable is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com