Digitalized construction site concrete prediction type anti-cracking method

A construction site, concrete technology, applied in the digital construction site concrete predictive anti-cracking field, which can solve the problems of adjusting concrete anti-cracking measures and not being able to grasp the changes of concrete internal temperature and stress in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

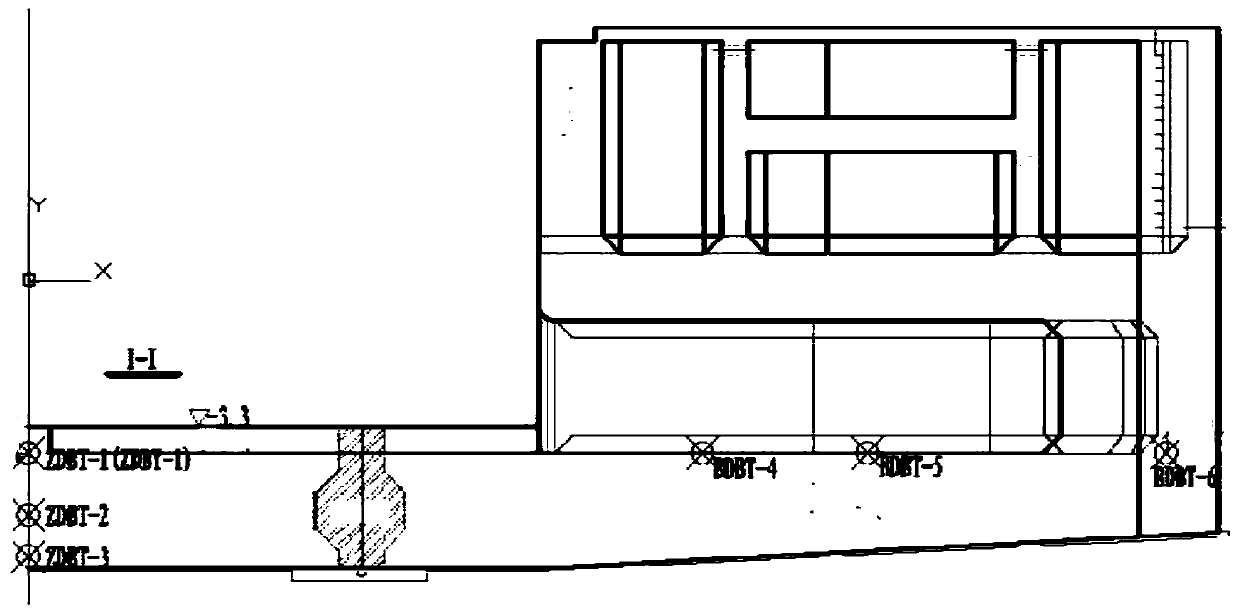

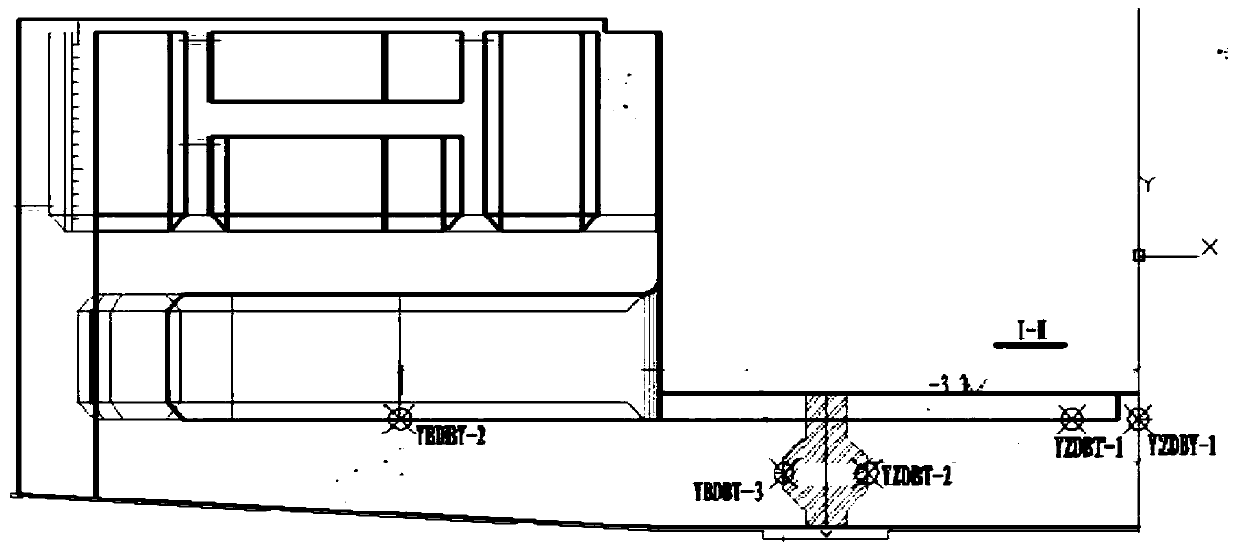

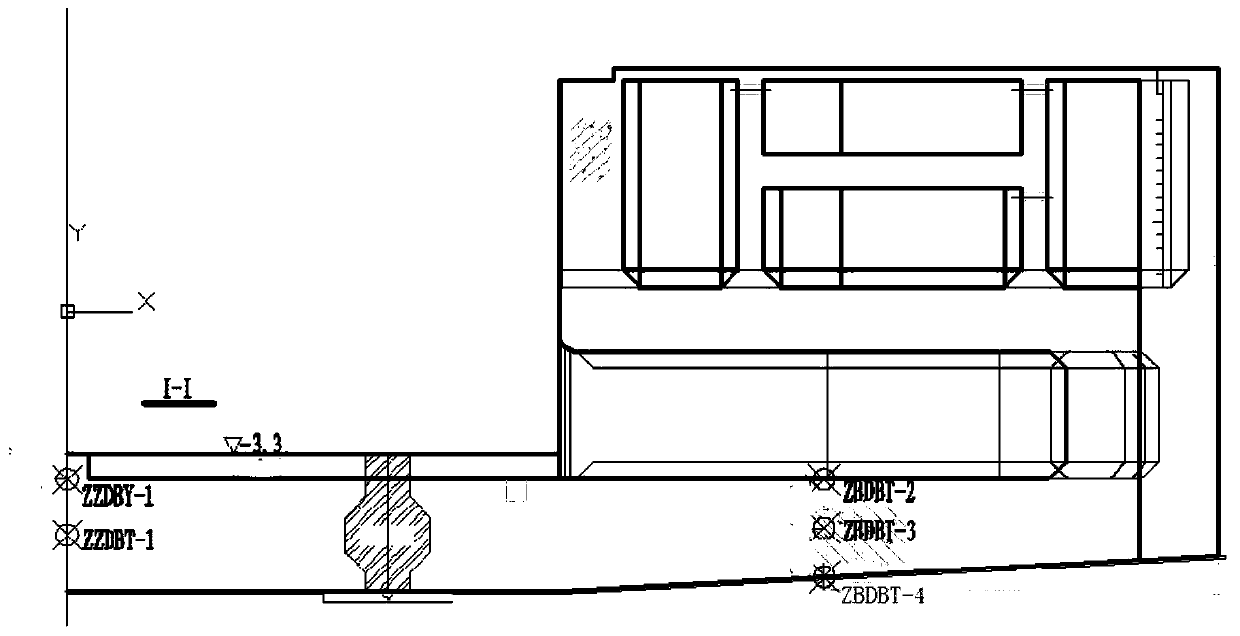

[0075] See figure 1 , which shows the flow chart of the digitalized construction site concrete anti-cracking method according to the present invention; the flow chart of this embodiment is as follows figure 2 shown. Arrange temperature sensors and stress sensors in sensitive parts inside the ship lock, and install data acquisition equipment in parts that do not affect the construction. The sensor layout positions are as follows: Figure 3-5 shown.

[0076] The temperature sensor of the ship lock adopts the DW-1 differential resistance thermometer, which is arranged in the conventional temperature monitoring position of the concrete engineering, including the upper surface, middle and lower surface of the middle bottom plate center of the upper lock head on the left bank; the side bottom plate of the upper lock head on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com