3D printing internal supporting structure design method based on force transmission path analysis

A technology of structural design and internal support, applied in computing, instrumentation, electrical and digital data processing, etc., can solve the problems of non-optimal design effect, unreasonable topology structure, low molding efficiency, etc., to improve specific strength and improve molding efficiency. , the effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

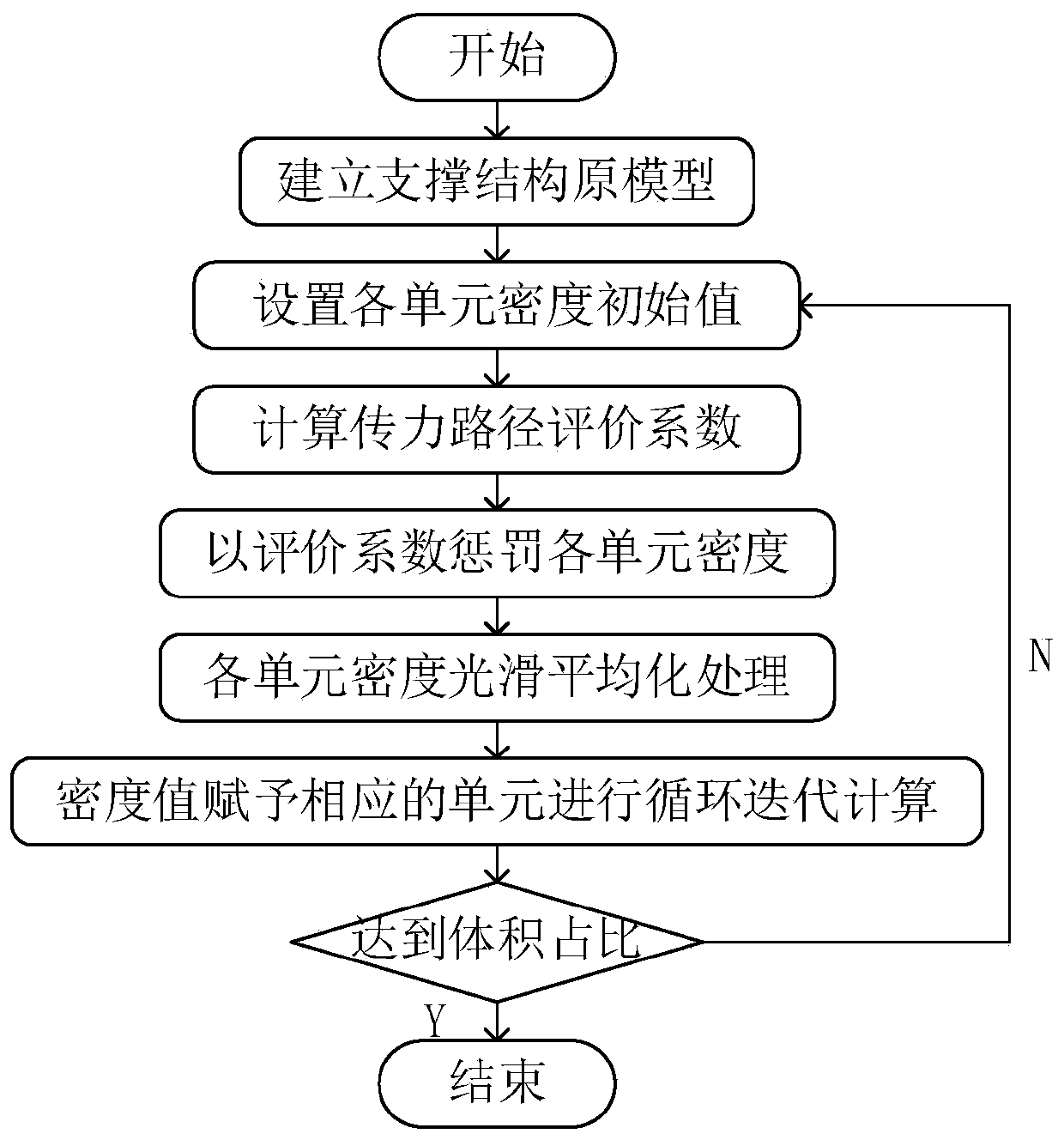

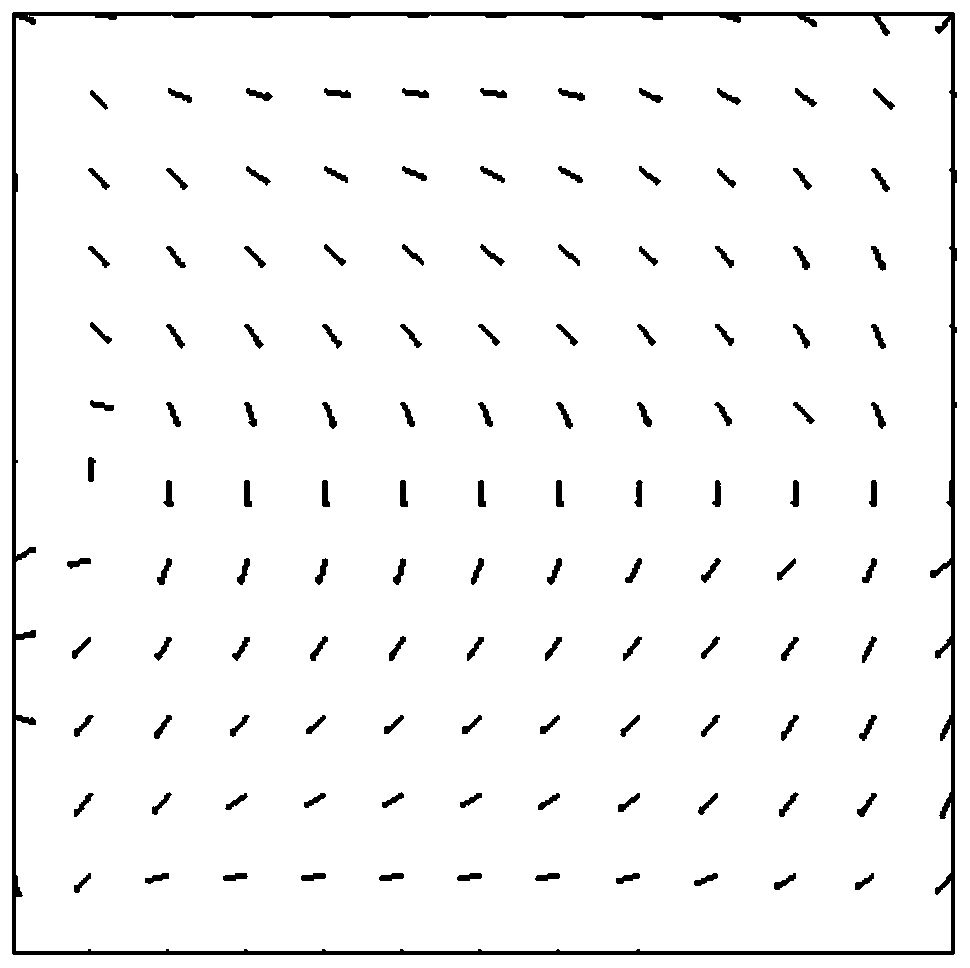

[0036] A 3D printing internal support structure design method based on force transmission path analysis, the flow chart is as follows figure 1 shown. Firstly, the force transmission path of the structure is extracted, then the force transmission performance of the structure is evaluated according to the characteristics of the force transmission path, and the evaluation coefficient is determined; finally, based on the SLM process, the evaluation coefficient is applied to realize the layout optimization of the support structure.

[0037] The method content includes the following steps:

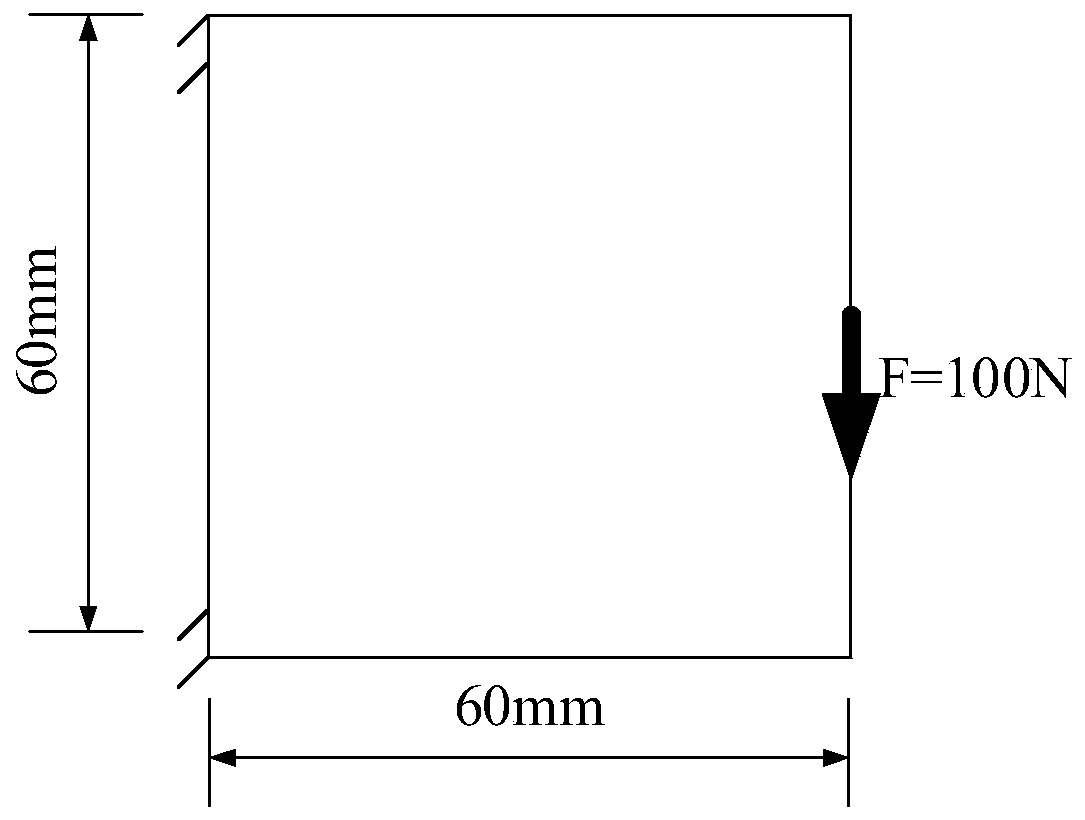

[0038] (1) Use the finite element simulation model to establish the finite element simulation model of the bearing structure, use the software to impose boundary conditions and solve the stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com