Lithium-ion battery positive electrode slurry and preparation method and lithium-ion battery positive electrode plate

A lithium-ion battery and positive electrode slurry technology, which is applied to battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as poor battery cycle performance, achieve better cycle performance, improve processing performance, and improve adhesion effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

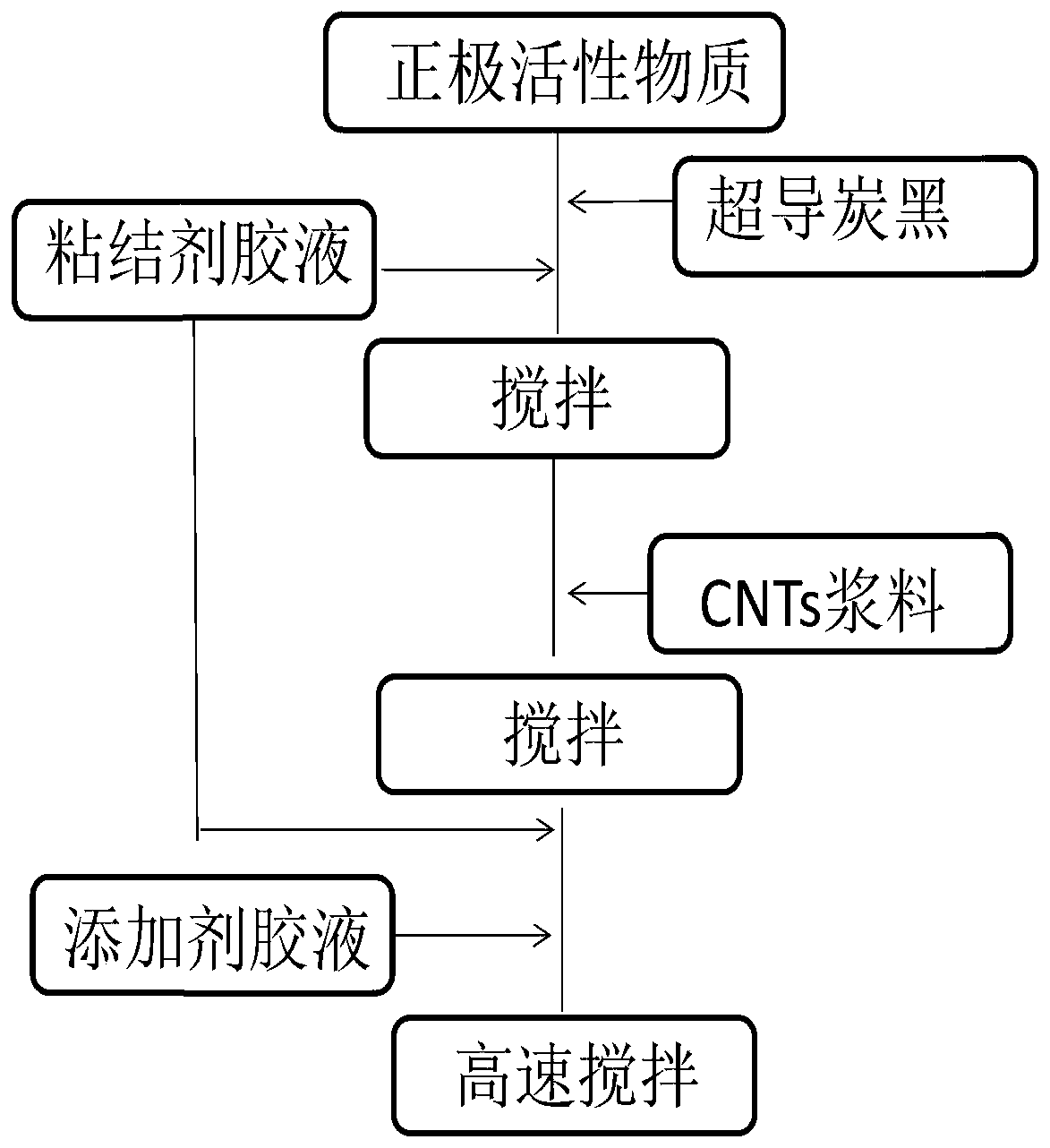

[0033] The preparation process of positive electrode slurry in this embodiment is as follows figure 1 As shown in , add Solvay PVDF 5130 into N-methylpyrrolidone and stir and mix to make an adhesive glue solution with a solid content of 6%. The adhesive glue solution is divided into two parts, respectively accounting for the The first glue solution of 40% of the binder glue quality, and the second glue solution of the remainder;

[0034] Add the polyphosphazene additive [NP(Ph)F]n into N-methylpyrrolidone and stir and mix to prepare an additive glue with a solid content of 6%;

[0035] With Li[Ni 0.8 co 0.1 mn0.1 ]O 2 As the positive active material, in Li[Ni 0.8 co 0.1 mn 0.1 ]O 2 Add superconducting carbon black and mix evenly, then add the first glue, after stirring and kneading, add the carbon nanotube slurry (wherein the diameter of the carbon nanotube is 8nm, and the length of the tube is 5 μm) with a solid content of 6%, continue to stir, Finally, add the second...

Embodiment 2

[0038] The preparation of the positive electrode slurry in this example is exactly the same as that in Example 1.

[0039] Coat the prepared positive electrode slurry evenly on the aluminum foil, and the surface density of one side coating is 300g / m 2 Bake and dry to obtain a positive electrode sheet.

Embodiment 3

[0041] The preparation of the positive electrode slurry in this example is exactly the same as that in Example 1.

[0042] Coat the slurry evenly on the aluminum foil, the surface density of one side coating is 150g / m 2 Bake and dry to obtain the desired positive electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com