A combined air cooling device for subway traction converter

A traction converter and air-cooling device technology, applied in the field of rail transit, can solve the problems of rising temperature of power devices, low heat flux density of radiators, and inability of heat exchange devices to effectively dissipate heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

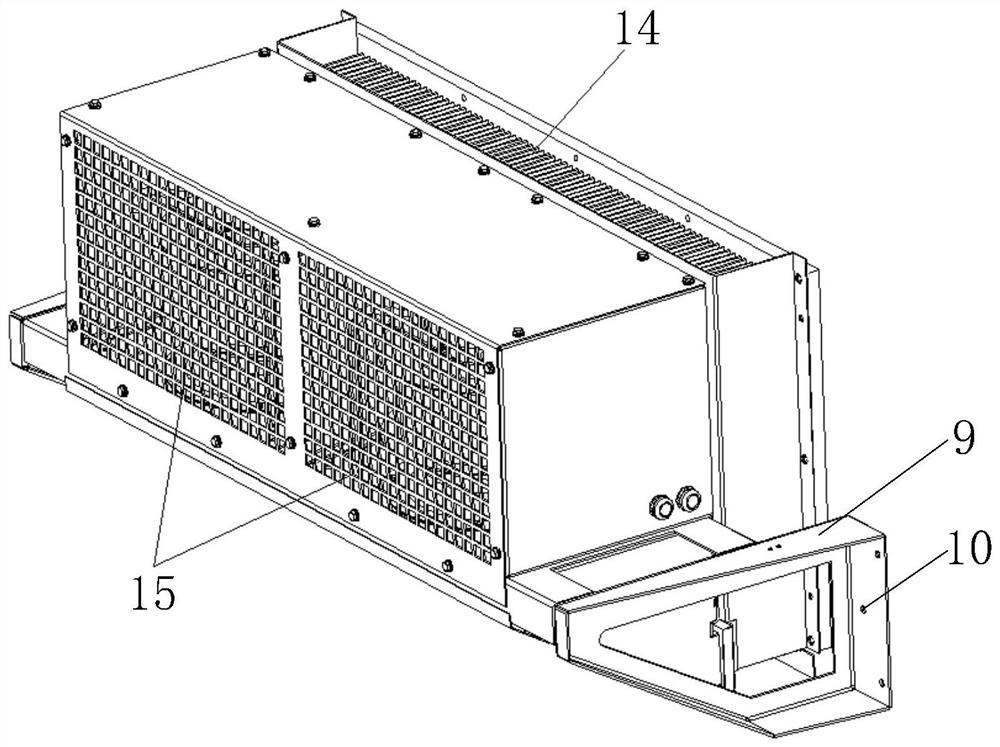

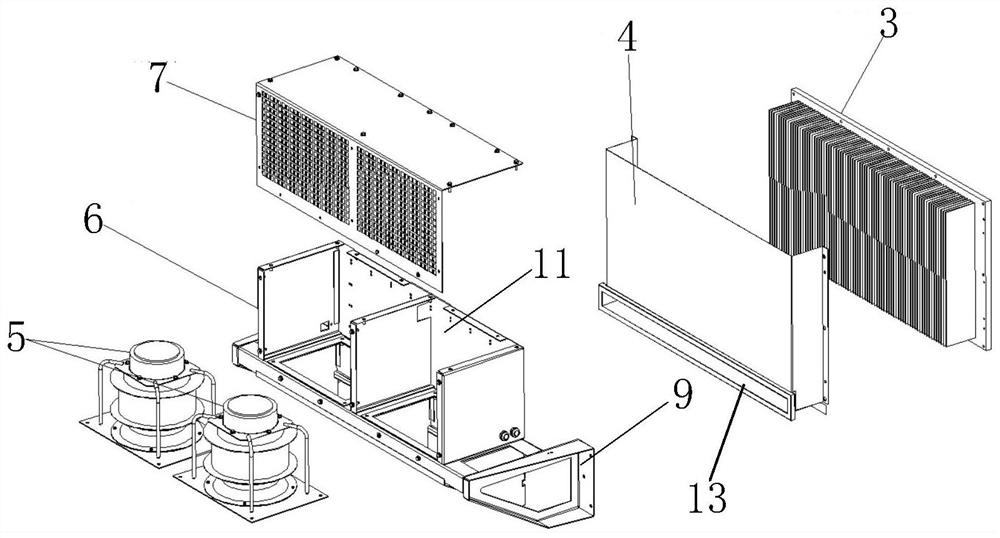

[0029] see Figure 1-3 As shown, the present invention provides a combined air-cooling device for subway traction converters, which includes a detachable air inlet assembly 1 and an air outlet assembly 2, and the air inlet assembly 1 and the air outlet assembly 2 are connected through an air duct connection; The air inlet assembly 1 includes a radiator 3 and an air inlet cover 4, and the radiator 3 and the air inlet cover 4 are detachably connected; the air outlet assembly 2 includes an adjustable-speed cooling fan assembly 5, a fan frame assembly 6, and a fan cover The plate 7 and the adjustable-speed cooling fan assembly 5 are installed in the fan frame assembly 6 , and the fan cover plate 7 is detachably connected with the fan frame assembly 6 .

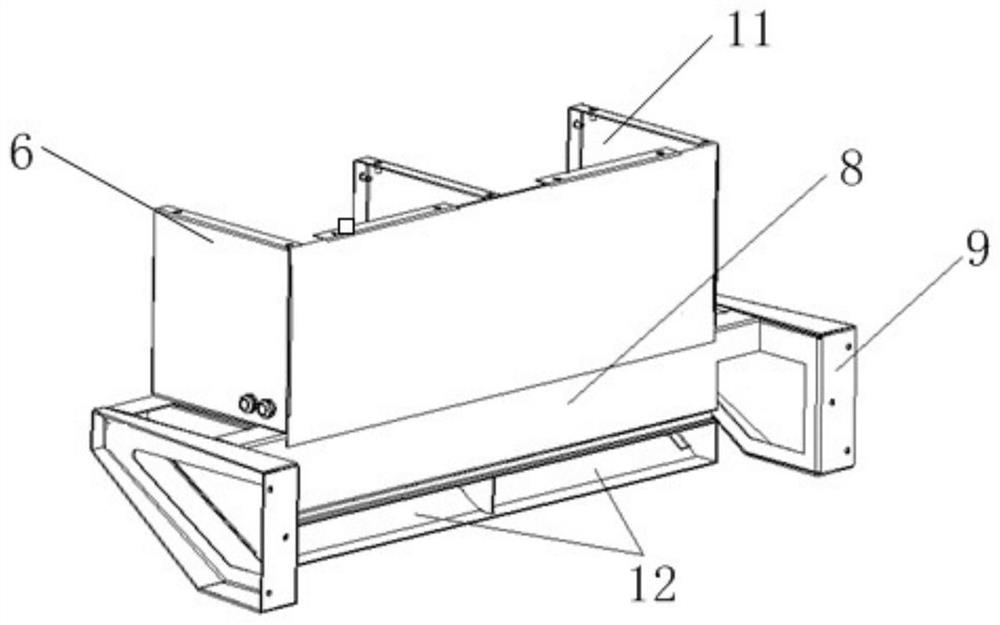

[0030] Further, the fan frame assembly 6 includes a trapezoidal air duct body 8, the two ends of the trapezoidal air duct body 8 are provided with mounting feet 9, the top of the trapezoidal air duct body 8 is provided with a fan ...

Embodiment 2

[0042] On the basis of Embodiment 1, the present invention also provides a practical application schematic diagram of a combined air-cooling device for a subway traction converter, see Figure 5 shown. The combined air-cooling device is used as a whole to dissipate heat from the IGBT power device 17. The adjustable-speed cooling fan assembly 5 is an adjustable-speed centrifugal fan assembly. The fan frame assembly 6 consists of two mounting feet, a trapezoidal air duct body 8 and Two fan assembly installation parts 11 are formed, and the working process of the whole air cooling device is as follows:

[0043] The combined air cooling device is assembled into a whole, and the IGBT power device 17 inside the converter is directly fixed on the radiator substrate 16; the air cooling device is connected to the traction converter through the mounting feet 9 on both sides of the air outlet assembly On the cabinet body of the converter, the heat generated by the IGBT power device 17 i...

Embodiment 3

[0045] On the basis of Embodiment 1, the present invention further provides a practical application schematic diagram of a combined air-cooling device for a subway traction converter after being split into an air inlet assembly and an air outlet assembly, see Figure 6 shown. The combined air cooling device is divided into air inlet component 1 and air outlet component 2 for use. The specific working process is as follows:

[0046] The combined air-cooling device is divided into an air inlet assembly 1 and an air outlet assembly 2, and the air inlet assembly 1 is assembled with the IGBT power device 17, the IGBT power device connection line 18 and other auxiliary devices to form an independent power unit. The power unit is directly assembled on the converter, and the air outlet assembly 2 is independently assembled on the converter, and the second air duct connection port 13 of the air outlet assembly 2 is spliced with the first air duct connection port 12 of the air intake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com