H-shaped piezoelectric ultrasonic driver and security protection device

A piezoelectric ultrasonic and drive technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of many parts, complex assembly, increased space and cost, etc. problems, achieve the effect of reducing space, simplifying assembly, reducing space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

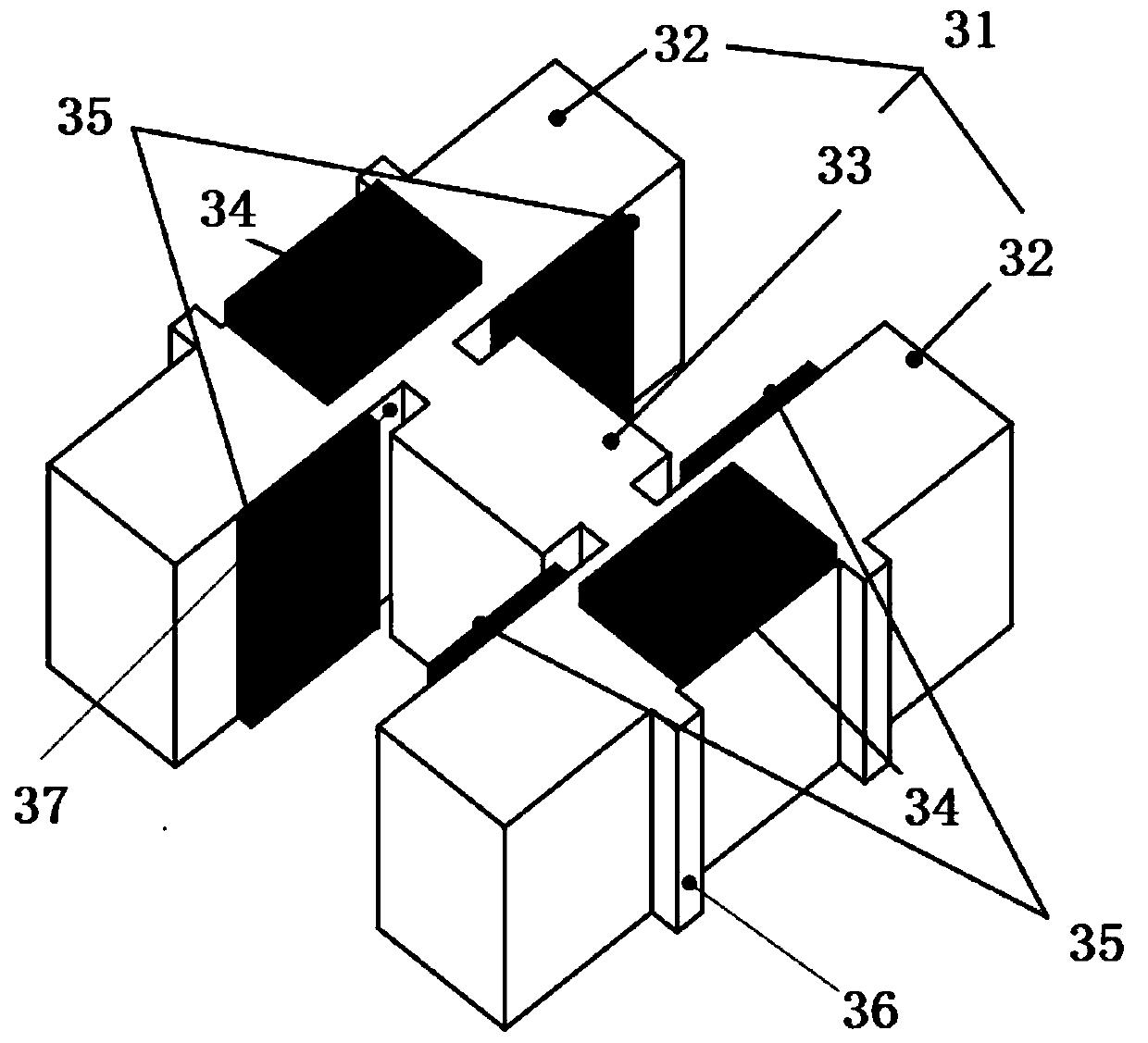

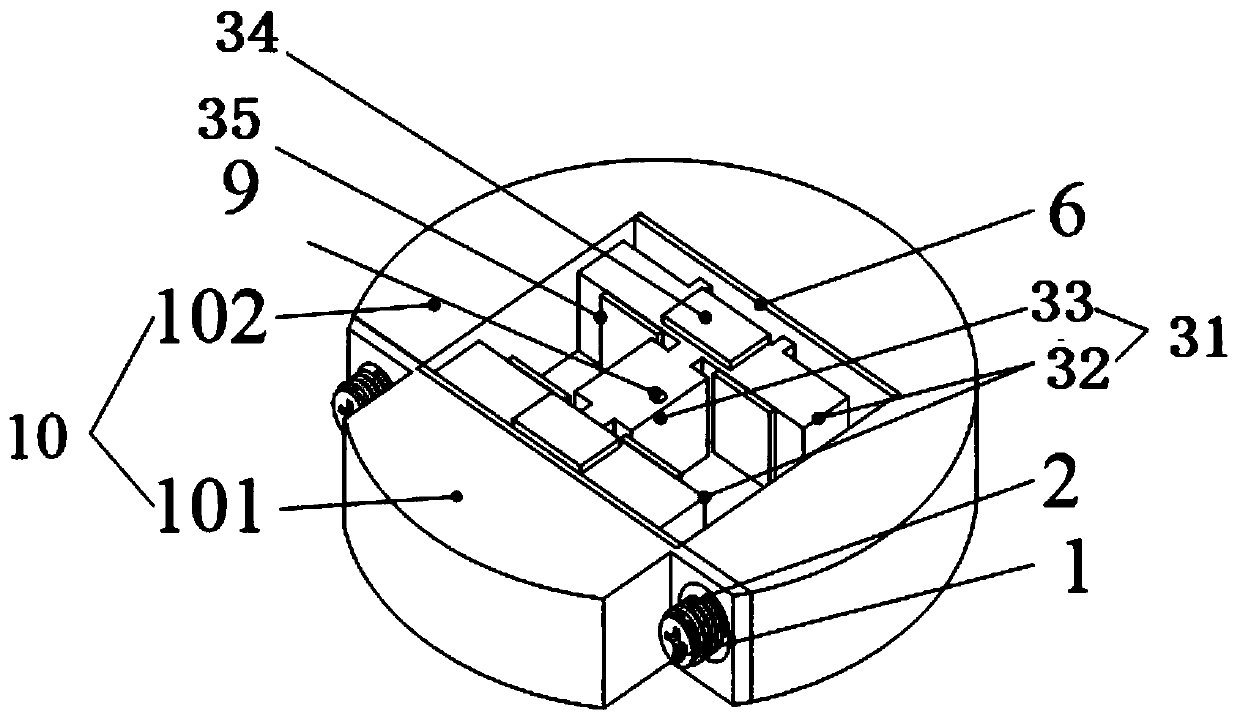

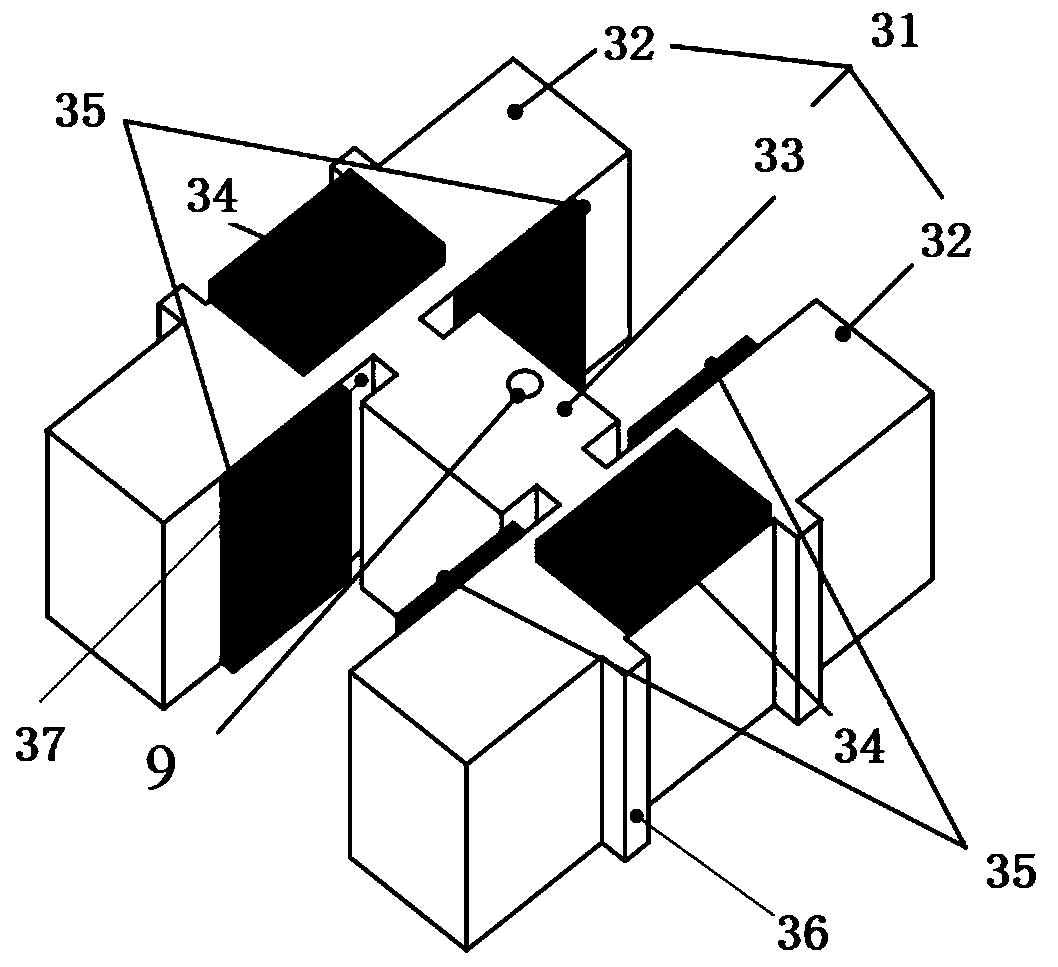

[0025] combine figure 1 , an H-shaped piezoelectric ultrasonic driver with a centrosymmetric structure, including an I-shaped metal base 31 and piezoelectric ceramics. The I-shaped metal matrix 31 includes two beams 32 and a vertical beam 33 connecting the centers of the two beams 32, and the drive feet 36 are set on the outside of the two beams 32; the piezoelectric ceramics include two pieces of longitudinal vibration piezoelectric ceramics 34 and four The sheet bending piezoelectric ceramics 35 and longitudinal vibration piezoelectric ceramics 34 are respectively arranged on the upper surface of the corresponding beam 32 , and the bending vibration piezoelectric ceramics 35 are respectively arranged on the inner surface of the beam 32 on both sides of the vertical beam 33 .

[0026] The I-shaped metal base 31 is an integral cutting part.

[0027] The two side walls of the vertical beam 33 are provided with slots 37 at the joints with the cross beams 32 , and the depths of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com