Method for making lead frames for integrated circuit packages

A technology of lead frame and forming lead, which is applied in the direction of circuit, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve the problems of long delivery time and waste of conductive layer manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Throughout the drawings, like reference numerals refer to like elements, and the various features are not necessarily drawn to scale. In this specification, the term "couples or couples" includes indirect or direct electrical or mechanical connections or combinations thereof. For example, if a first device is coupled to or with a second device, the connection may be through a direct electrical connection, or through an indirect electrical connection through one or more intervening devices and connections.

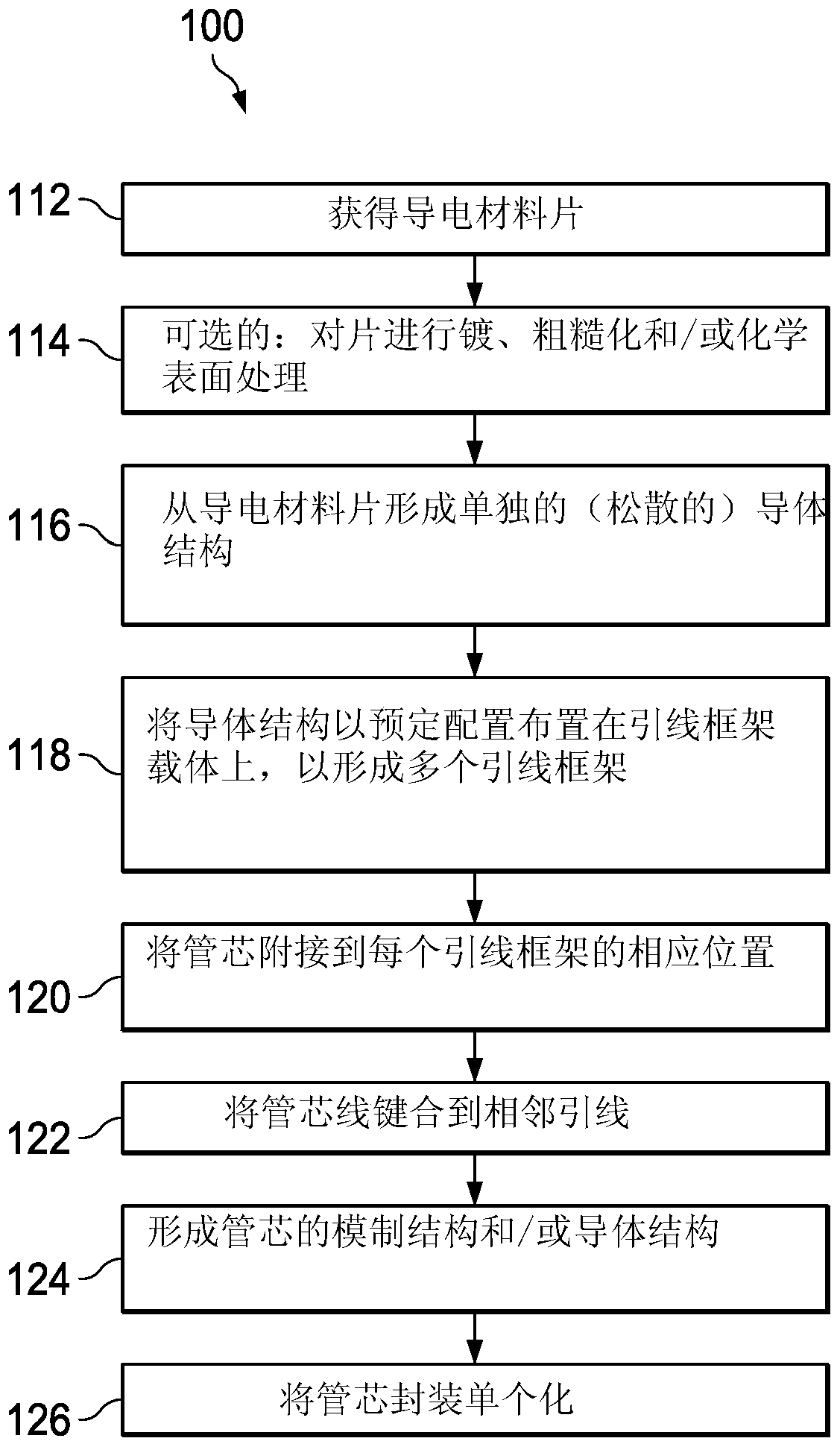

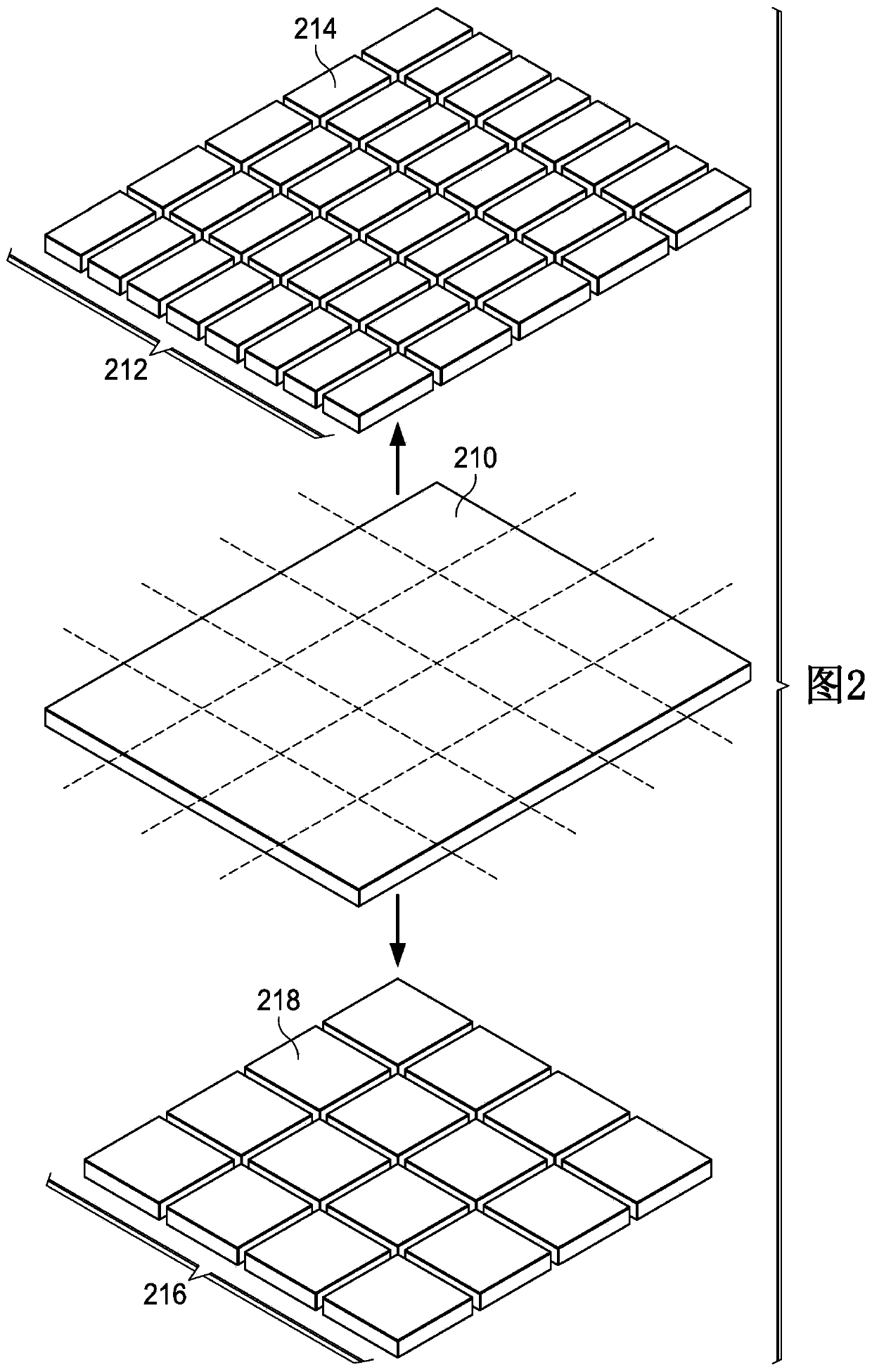

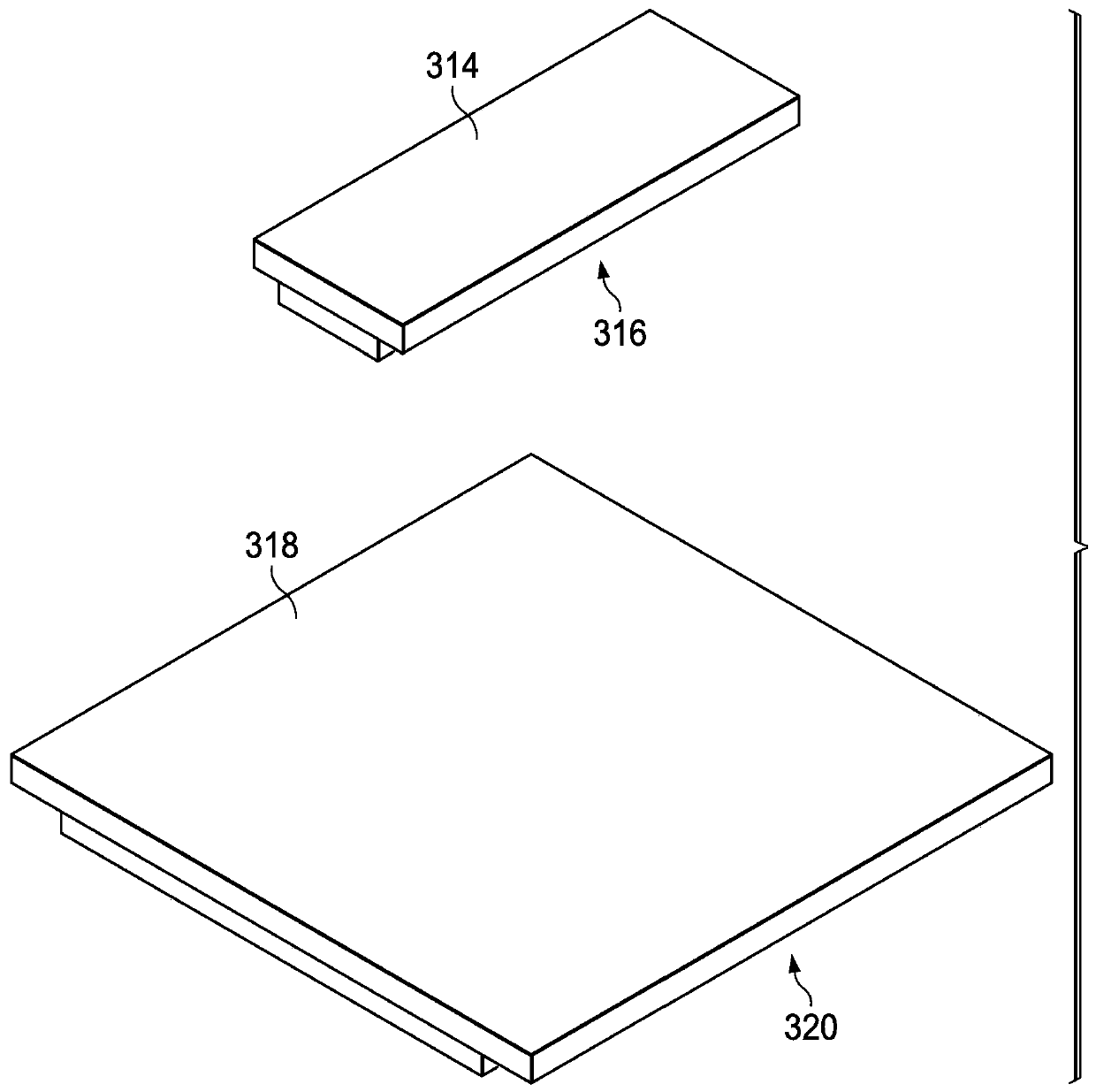

[0015] Example embodiments include methods of making leadframes that use nearly all conductor materials (incoming raw materials for leadframe conductor structures) and produce leadframes having spaced-apart conductor structures (and / or other types of structures), The spacing is less than one conductive layer thickness. This method enables the rapid generation of new leadframe configurations without redesign and can reduce the manufacturer's lead time. In one embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com