Device for grinding and processing polycrystalline silicon

A processing device, polysilicon technology, applied in grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problem of reducing product quality and yield, affecting the surface smoothness of edge, head and tail material, and obvious edge lines, etc. problems, to achieve the effect of reducing marks, increasing product quality, and increasing surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical means adopted by the present invention and the technical effects achieved, the following will be described in detail in conjunction with the accompanying drawings and embodiments.

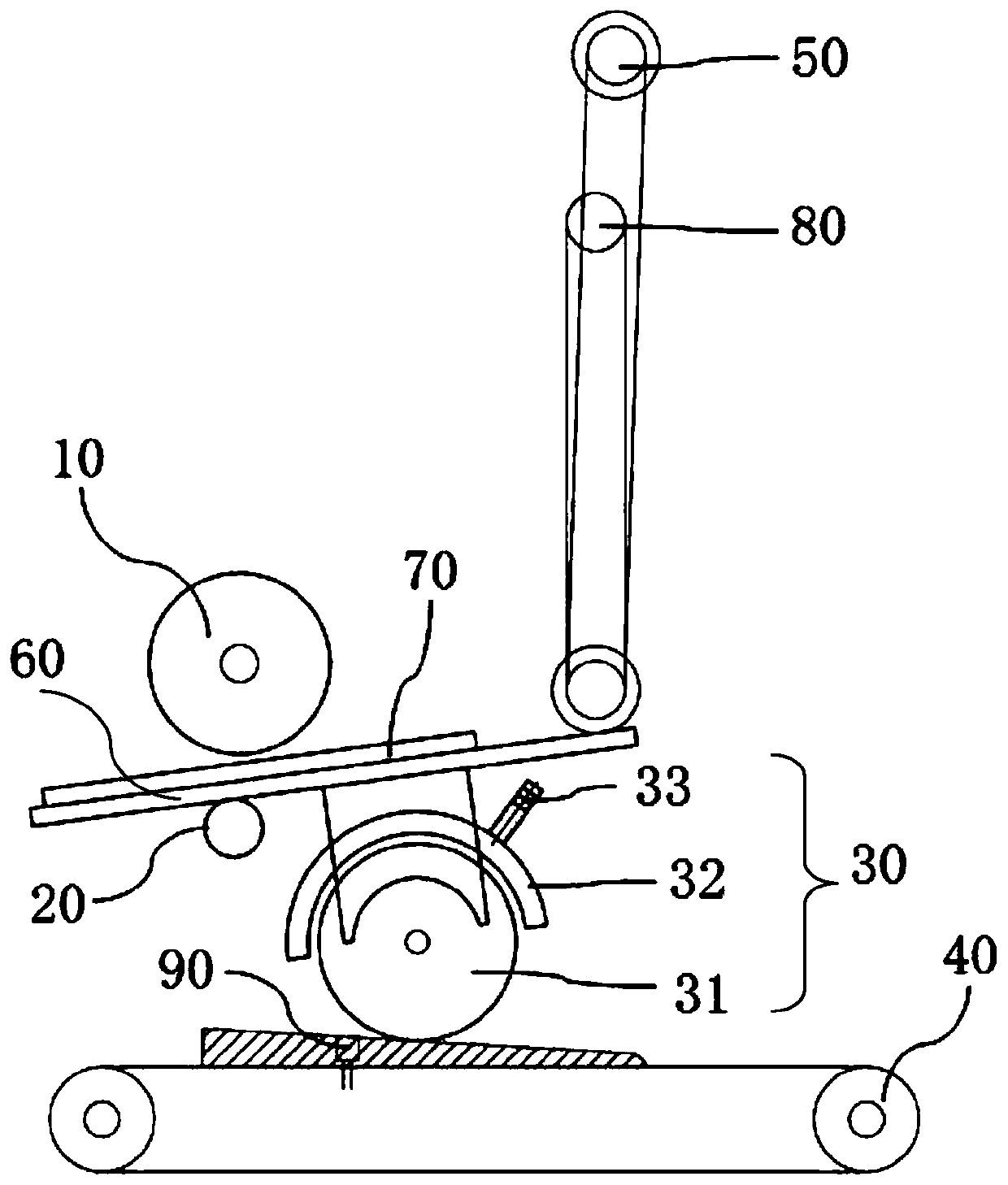

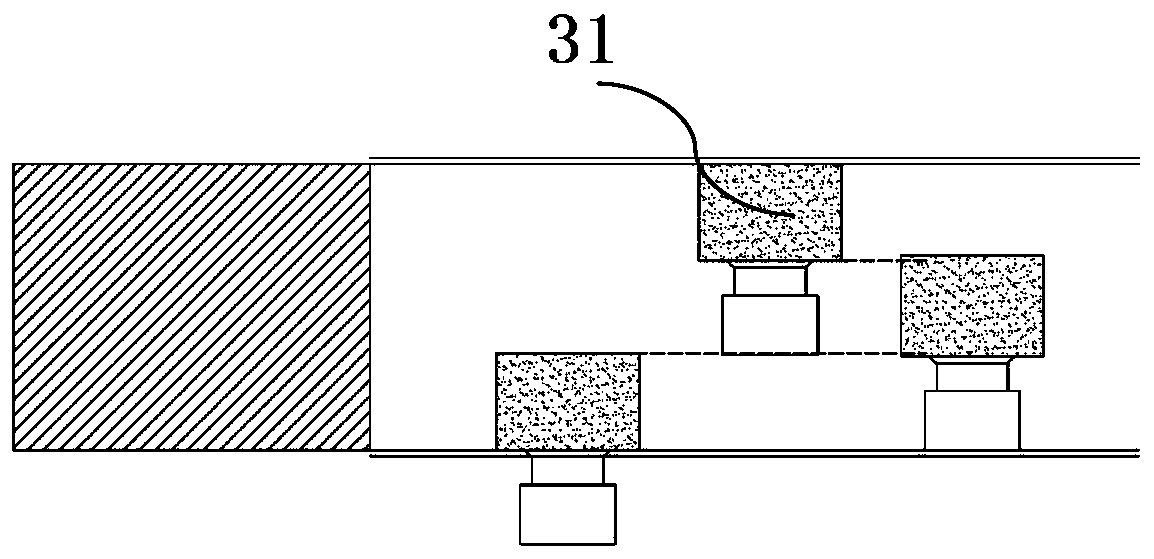

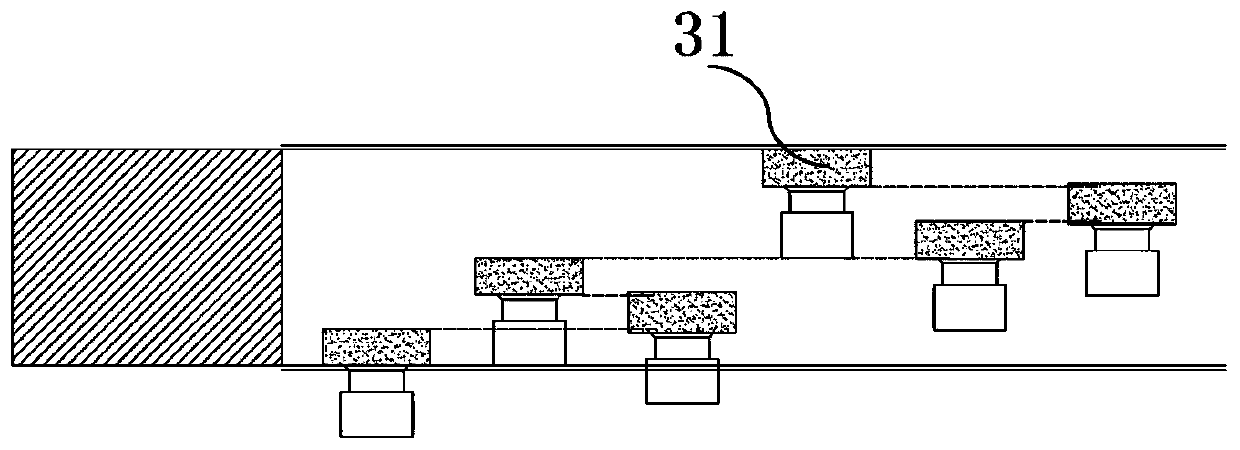

[0032] refer to figure 1 , the present invention provides a polysilicon grinding processing device, which includes a spindle motor 10, a spindle 20, a grinding tool 30, a conveying device 40, a lifting motor 50, a balance frame 60, a balance weight 70, a wire reel 80 and a proximity switch 90 . The main shaft motor 10 is connected with the main shaft 20 , the main shaft 20 is located directly below the main shaft motor 10 , and the main shaft 20 drives the grinding tool 30 to rotate. The balance frame 60 is arranged on the top of the grinding tool 30, the middle bottom of the balance frame 60 is fixedly connected with the grinding tool 30, the balance weight 70 is fixed on one end of the balance frame 60, and the wire reel 80 is fixed on the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com