A start-up construction method for a large-span cylindrical reticulated shell structure gable in a coal storage yard

A technology of cylindrical reticulated shell structure and construction method, which is applied in the direction of walls, building components, building structures, etc., can solve problems such as difficult displacement of hoisting equipment, influence on coal stacking operations, and complex site, achieving high installation accuracy, The effect of fast construction speed and high site utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail in combination with the embodiments and accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. The technical solutions of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings, but the scope of protection is not limited thereto.

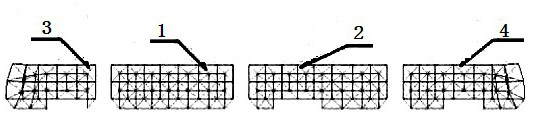

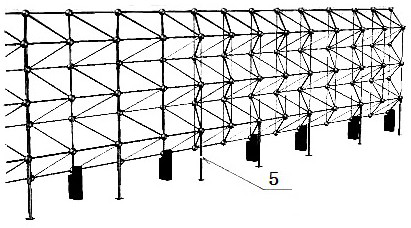

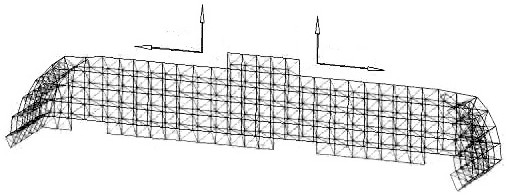

[0027] A fully enclosed coal yard project of a coking plant, with a plane size of 272m*130m and a construction area of 35468㎡. The roof structure is a three-core cylindrical reticulated shell, and the gables at both ends are closed with square pyramid flat grids. The height of the reticulated shell is 53m, the grid size is 4.8m*4m, the thickness of the reticulated shell is 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com