Mechanical and electrical integration harmonic reducer

A harmonic reducer, integrated technology, applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve the problems of complex structure, bulky, large size of the whole machine, and achieve the effect of high transmission accuracy, high efficiency and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

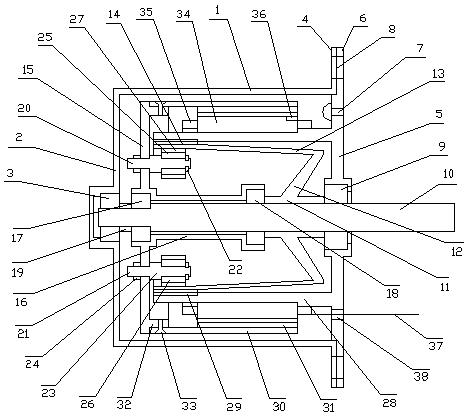

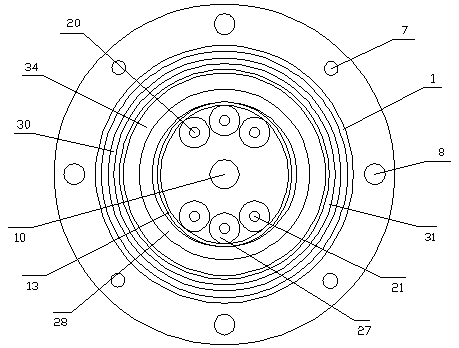

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0009] exist figure 1 , figure 2 Among them, the electromechanical integrated harmonic reducer is provided with a cylindrical shell 1, and the cylindrical shell is provided with a left end cover 2. The cylindrical shell and the left end cover are integrally manufactured and formed. There is a small bearing 3, a connecting plate 4 is provided at the right end of the cylindrical shell, a disc-shaped end cover 5 is provided at the right end of the connecting plate, a positioning ring 6 is provided on the disc-shaped end cover, and 4 rings are provided on the circumference of the connecting plate and the positioning ring. Fasten the screw 7, the circumference of the connection plate and the positioning ring is provided with upper, lower, left and right 4 mounting screw holes 8, the middle part of the disc-shaped end cover is provided with a right bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com