Thermal curing type heat-resistant holographic anti-counterfeiting film

A holographic anti-counterfeiting and thermal curing technology, applied in the field of anti-counterfeiting, can solve problems such as yellowing, adhesion, loss of holographic stripes, etc., and achieve the effect of not destroying clarity, improving stability, and ensuring integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

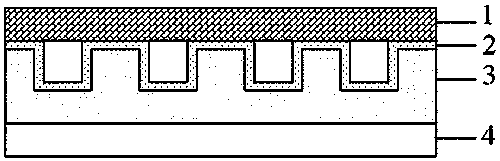

[0027] Such as figure 1 As shown, the heat-resistant holographic anti-counterfeiting film of the present invention is a layered structure, which sequentially includes a carrier layer (1), an anti-counterfeiting information layer (2), a release layer (3) and an adhesive layer (4) from outside to inside. The carrier layer (1) is a polyethylene terephthalate film, the anti-counterfeiting information layer (2) is a photocurable heat-resistant acrylic resin layer, and its heat-resistant temperature is above 260°C, and the curable heat-resistant acrylic resin layer Nanoscale fumed silica is added to the resin, the particle size of the nanoscale fumed silica is 20nm, the anti-counterfeit information layer (2) has a concave-convex holographic pattern, and the release layer (3) is poly Tetrafluoroethylene coating, the adhesive layer (4) is a hot melt adhesive layer. The thickness of the carrier layer (1) is 0.5µm, the thickness of the anti-counterfeiting information layer (2) is 1µm, ...

Embodiment 2

[0030] The structure of the heat-resistant holographic anti-counterfeiting film in this example is the same as the preparation method and Example 1, except that the particle size of nanoscale fumed silica in the curable heat-resistant acrylic resin is 35nm, and the carrier layer ( 1) has a thickness of 1 µm, the anti-counterfeiting information layer (2) has a thickness of 2 µm, the release layer (3) has a thickness of 0.5 µm, the adhesive layer (4) has a thickness of 1 µm, and the anti-counterfeiting The texture depth of the holographic pattern in the information layer (2) is 1 µm.

Embodiment 3

[0032] The structure of the heat-resistant holographic anti-counterfeiting film in this example is the same as that of Example 1, except that the anti-counterfeiting information layer (2) is a heat-cured heat-resistant acrylic resin layer, and the curable heat-resistant acrylic resin layer The particle size of the nanoscale fumed silicon dioxide is 50nm, the release layer (3) is a fluorocarbon coating, and the bonding layer (4) is a pressure-sensitive adhesive layer. The thickness of the carrier layer (1) is 0.8µm, the thickness of the anti-counterfeit information layer (2) is 1.5µm, the thickness of the release layer (3) is 0.35µm, the adhesive layer (4) The thickness is 0.8 µm, and the texture depth of the holographic pattern in the anti-counterfeit information layer (2) is 0.8 µm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com