Oil storage tank based on oil tanker

A technology for oil tankers and cabins, which is applied in the direction of hull bulkheads, hulls, and hull parts, etc. It can solve problems such as pollution, impact force of oil bulkheads, oil leakage, etc., and achieve high strength, strong impact resistance, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

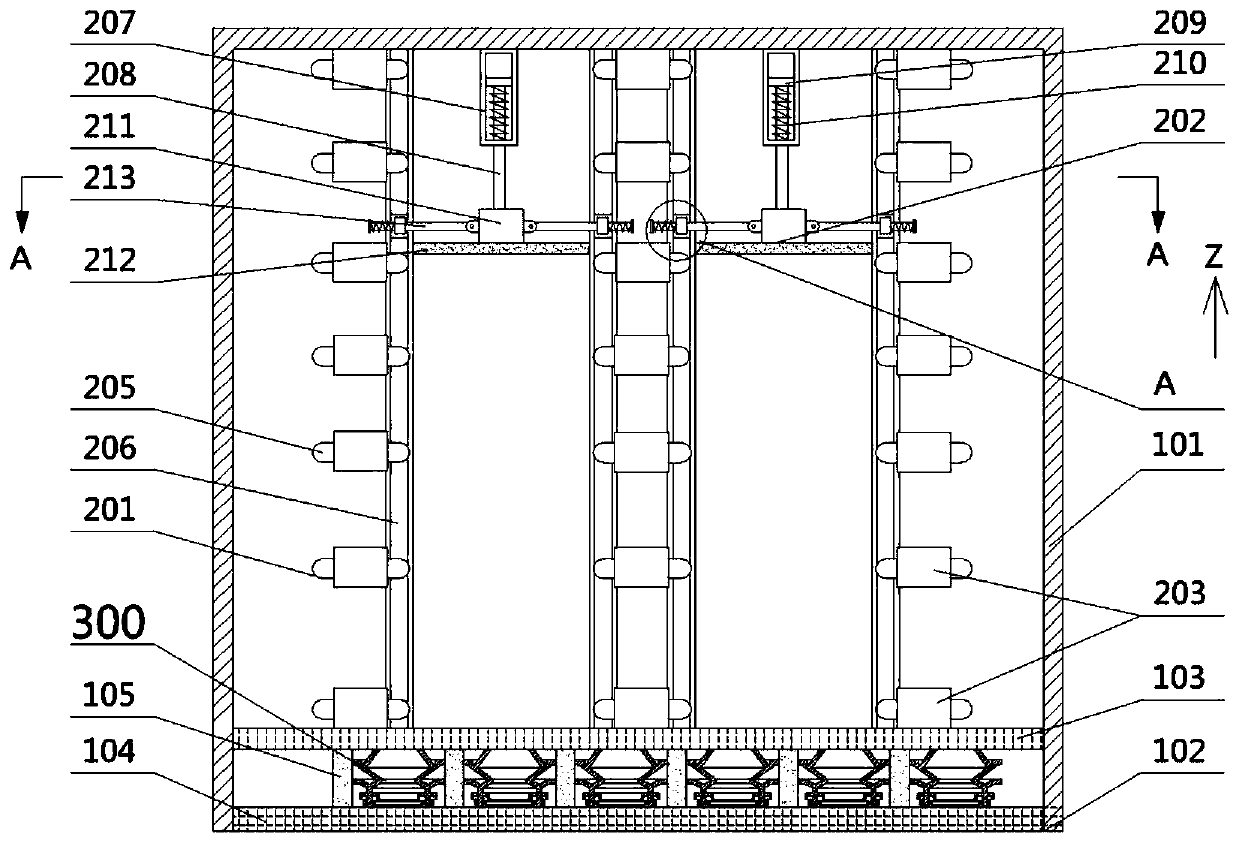

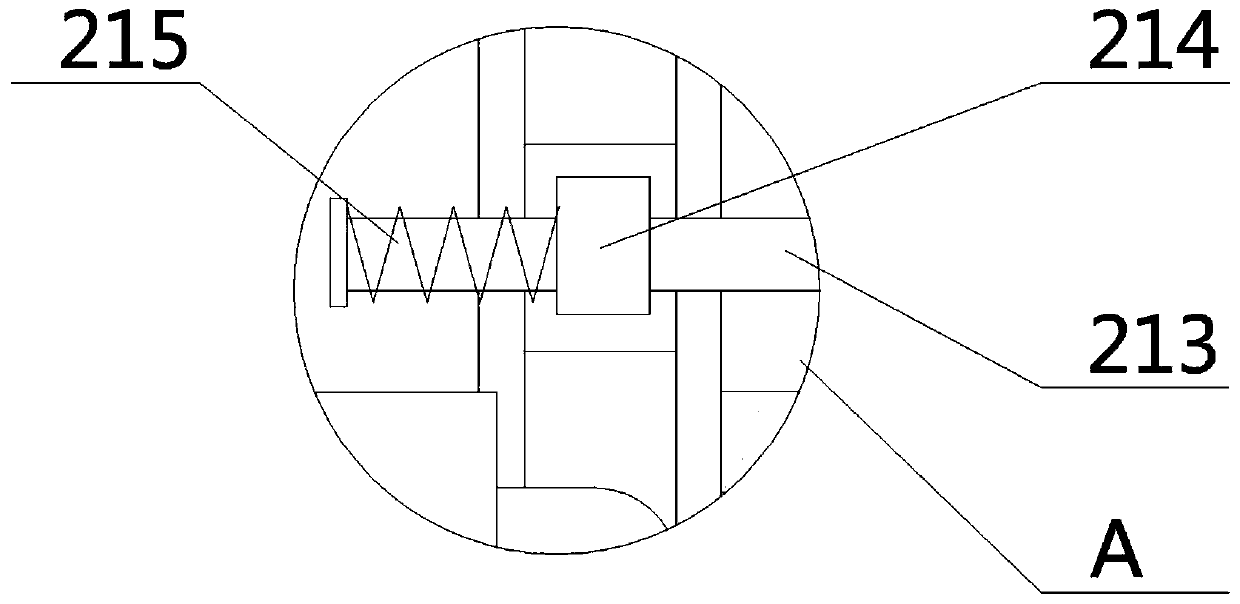

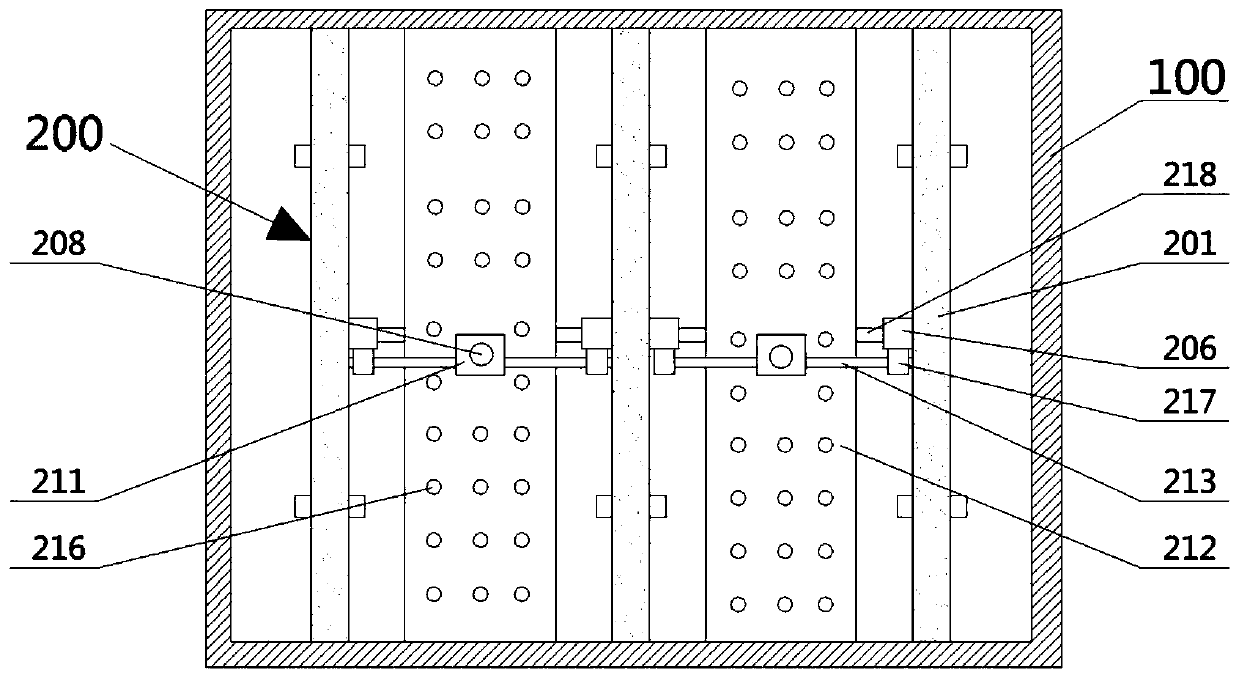

[0029] Such as figure 1 , Figure 5 As shown, an oil storage tank based on an oil tanker includes a cabin body 100, the cabin body 100 includes a bulkhead 101, and a base 102 installed at the bottom of the bulkhead 101, the base 102 includes an inner bottom plate 103, and the inner bottom plate 103 below Ship bottom plate 104, the upper end is installed on the inner bottom plate 103 and the lower end is installed on the ship bottom plate 104, a plurality of main ribs 105 distributed along the X direction, the upper end is installed on the inner bottom plate 103 and the lower end is installed on the ship bottom plate 104 distributed along the Y direction. The sub-floor 106, a plurality of reinforced areas 107 are formed between the main floor 105 and the sub-floor 106, which is characterized in that: the cabin body 100 is provided with a plural...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap