A buttress-type retaining wall with drainage function and its construction method

A buttress-type and retaining wall technology, which is applied in the field of buttress-type retaining walls and hydraulic factor-induced slope slope geological disaster prevention and control, can solve the problems of poor drainage performance, unfavorable upper soil drainage, and low drainage holes in the lower part, etc., to achieve Enhance the ability of anti-slip and anti-overturning, good drainage effect, flexible effect of retaining wall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

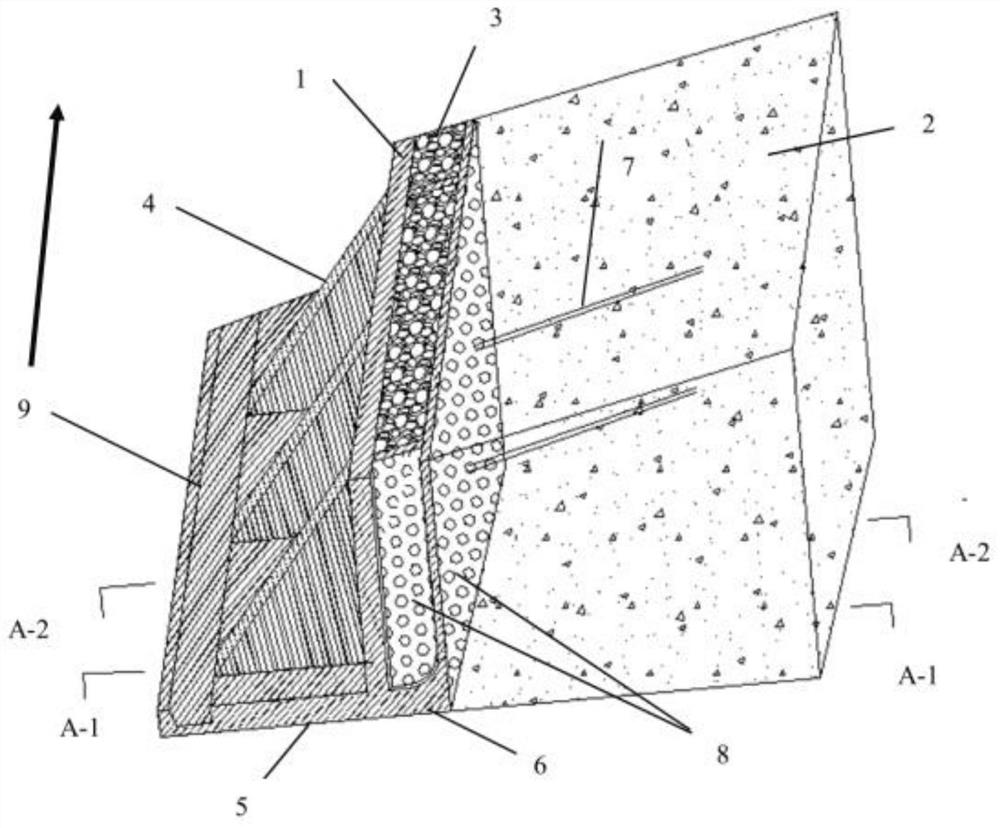

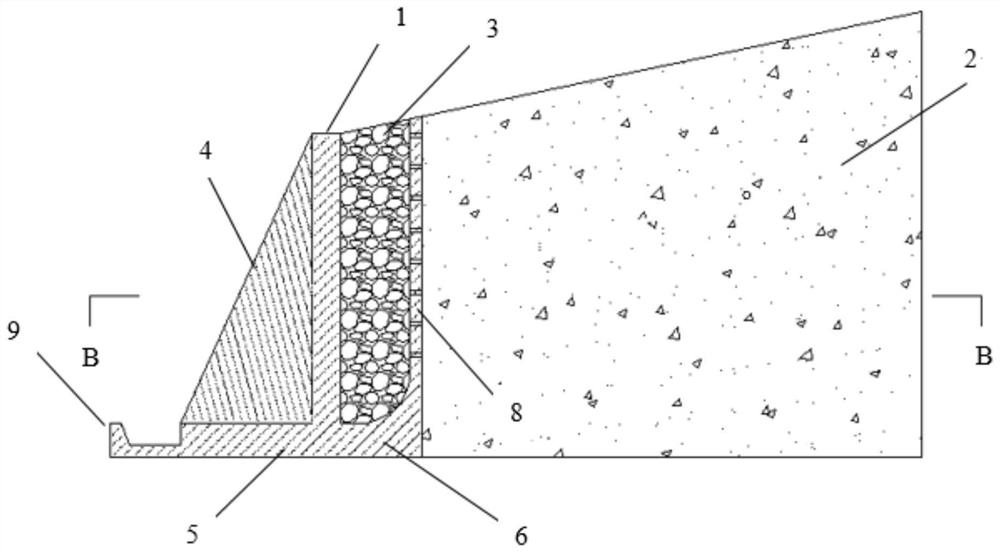

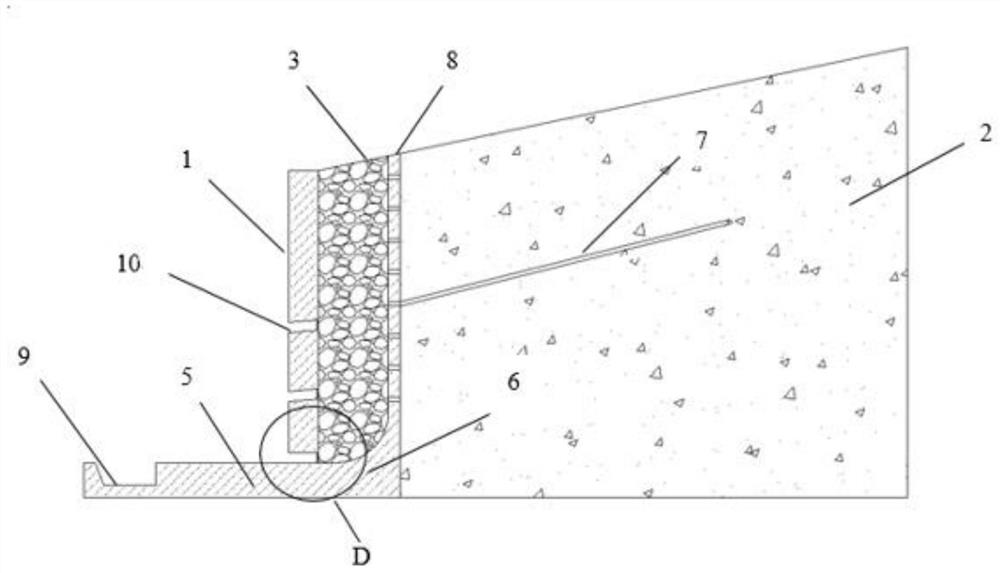

[0044] This embodiment discloses a buttress-type retaining wall with drainage function, including a main wall surface 1, a buttress 4, a wall heel board 5, a wall toe board 6, a water guide pipe 7, a water guide wall 8, a drainage ditch 9, a drainage hole 10;

[0045] refer to figure 1 , Figure 5, the side of the main wall 1 is provided with a retaining body 2, which is suitable for a relatively large height range, and should not exceed 15m, generally 6-12m, wherein the lower part of the main wall is provided with three rows of drainage through the retaining wall The hole 10 extends along the length of the retaining wall ( figure 1 The length of the construction section in the direction indicated by the middle arrow) shall not exceed 20m, and the width of the topmost wall of the main wall 1 shall not be less than 0.2m;

[0046] refer to figure 2 , Figure 4 , the buttress 4 is arranged on the other side of the main wall 1, and the thickness of the buttress is changed ac...

Embodiment 2

[0053] This embodiment discloses a construction method for the buttress-type retaining wall structure with drainage function described in Embodiment 1, which includes the following steps:

[0054] S1. According to the actual engineering needs and the principle of economical practicability, design and determine the parameters and dimensions of the buttress-type retaining wall (determine the height and width of the main wall, the size of the buttress, and the toe board according to the size of the retained soil body) , the size of the wall heel board), and complete the construction drawing; S2. Measurement and setting out: divide the construction section according to the construction drawing, and measure the subgrade centerline and foundation at the position of the wall toe board (the main wall surface, the wall toe board, and the wall heel board constitute Foundation) main axis, wall top (the wall top of the main wall) axis, retaining wall start and end point and cross section, ...

Embodiment 3

[0064] In the construction method of this embodiment, after step S2 in the implementation method of embodiment 2, the lower part of the retaining body is drilled, and the drilled holes are used to place the water pipe. Afterwards, steps S3-S8 are executed, and after the crushed stone and earthwork both reach the specified height, compaction is performed to complete the construction.

[0065] What is not mentioned in the present invention is applicable to the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com