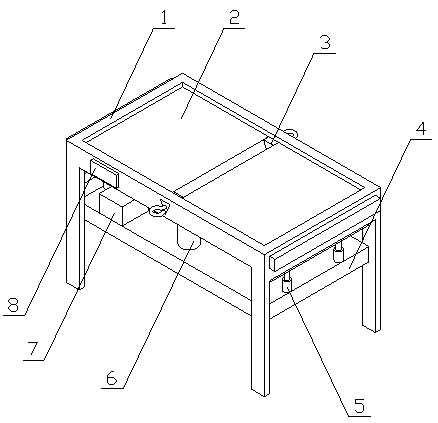

Welding heat circulation curve measuring instrument

A welding heat cycle and measuring instrument technology, applied in the field of mechanical processing, can solve the problems of plate waste, troublesome operation, heavy workload, etc., and achieve the effect of accurate measurement, small workload and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

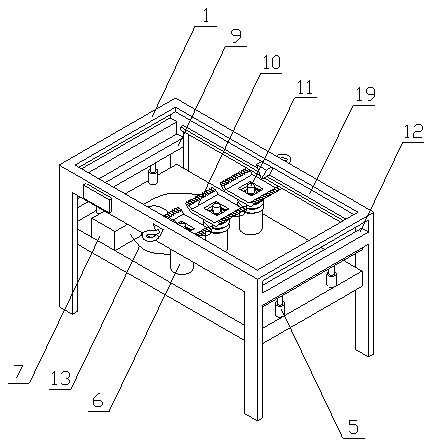

Examples

Embodiment 2

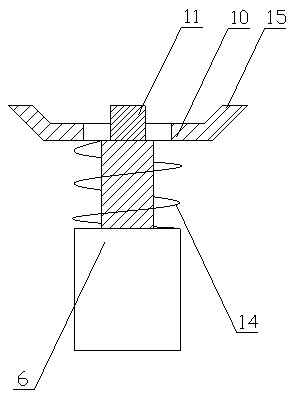

[0027] The difference between this embodiment and embodiment 1 is: the surface of the non-slip tooth (15) is provided with a heat-resistant pad (16); during use, due to the heat conduction temperature of the welding plate (2) during welding, the heat-resistant pad (16) ) It can protect the push plate (10) from damage;

Embodiment 3

[0029] The difference between this embodiment and the first embodiment is that four secondary springs (17) are arranged on the plane of the pressing plate (10), and they are respectively located at four corner positions of the plane of the pressing plate (10); When in use, it can provide stronger support for the laminated push plate (10) and more stable support for the welding of the two welding plates (2);

Embodiment 4

[0031] The difference between this embodiment and embodiment 1 is: a set of suction cups (18) are respectively placed on both end faces of the laminated push plate (10), and a group of suction cups (18) is composed of two suction cups (18), and Close to the two ends of the push plate (10) respectively; when in use, the welding plate (2) can be effectively attached to prevent the phenomenon of not tightly attaching from affecting the measurement;

[0032] The thermocouple (11) can detect the temperature of the weld in real time, and transmit the detection signal to the data processor (7);

[0033] A computer program is stored in the data processor (7), and the following steps are implemented when the program is executed:

[0034] Receive the temperature signal transmitted by the thermocouple (11), and perform data processing to obtain the thermal cycle curve of the current welding process, and transmit it to the display (8);

[0035] The display (8) and the data processor (7) exchange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com