Multichannel super-soft low-loss high temperature-resistant vehicle-mounted CAN signal bus

A signal bus, low-loss technology, applied in the direction of conductors, climate change adaptation, insulated cables, etc., can solve problems such as extrusion, torsion, impact, and CAN bus stability, achieve high damping, improve heat exchange efficiency, The effect of increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

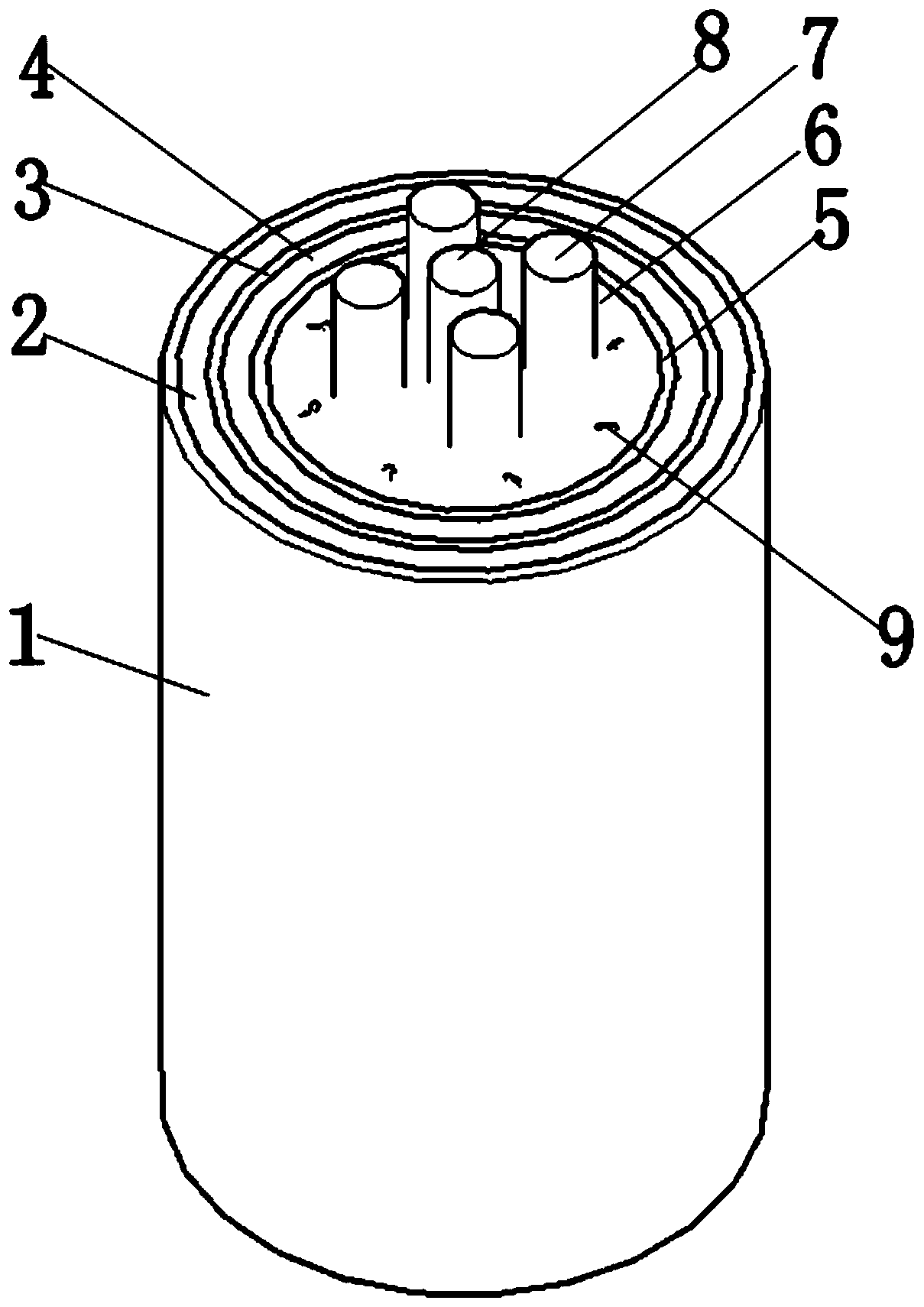

[0069] The inside of the filling layer 3 6 is provided with a plurality of special-shaped heat pipes 1 9;

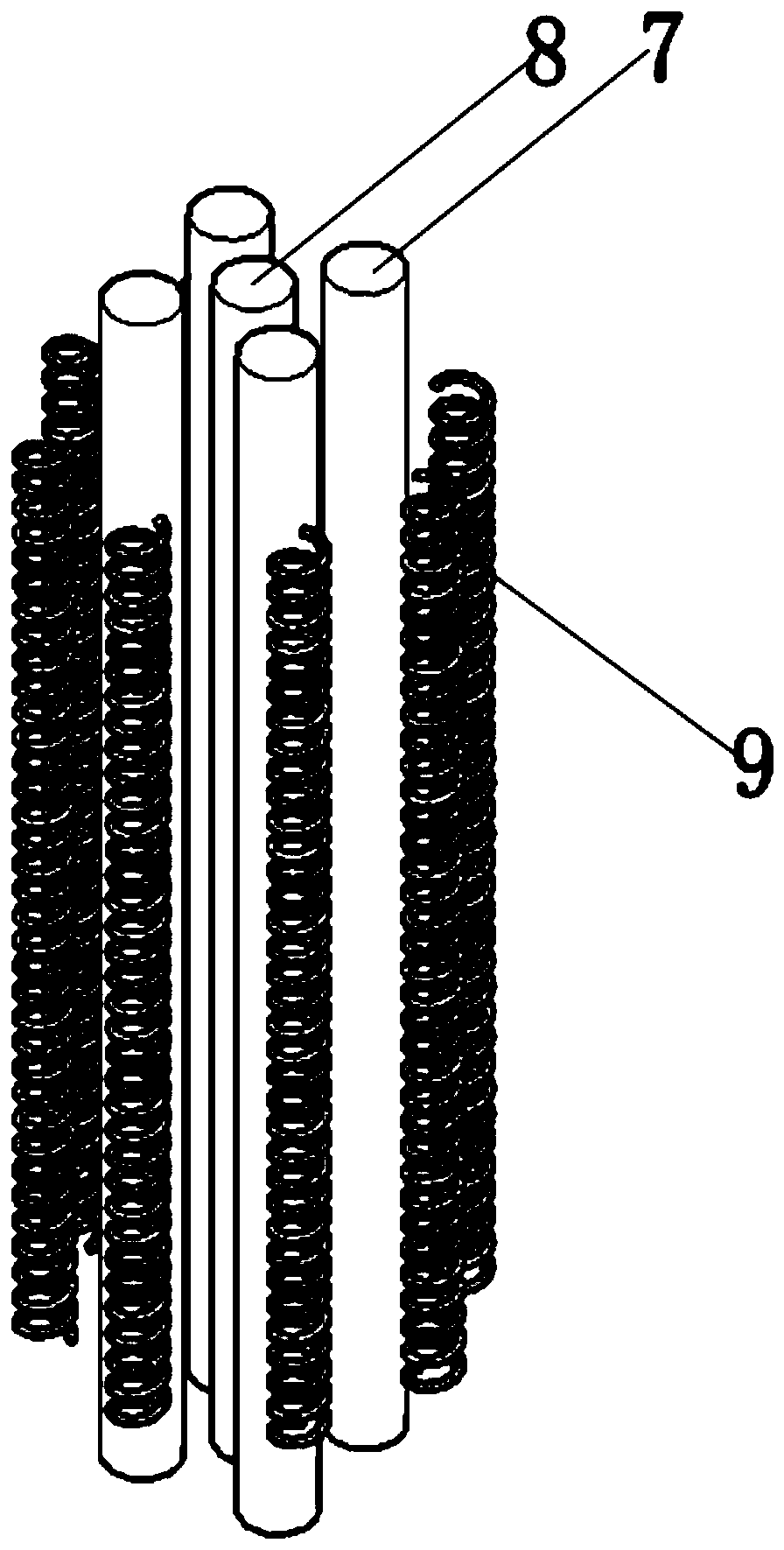

[0070] Such as figure 2 As shown, the special-shaped heat pipe-9 is a spiral micro heat pipe;

[0071] Each of the special-shaped heat pipes 19 is arranged parallel to the axial direction of the transmission line 7, and a plurality of special-shaped heat pipes 19 are arranged around and arranged in the filling layer 3 6;

[0072] The shell of the special-shaped heat pipe-9 is made of aluminum material, and the outer wall of the special-shaped heat pipe-9 is provided with a foamed aluminum layer;

no. 2 example

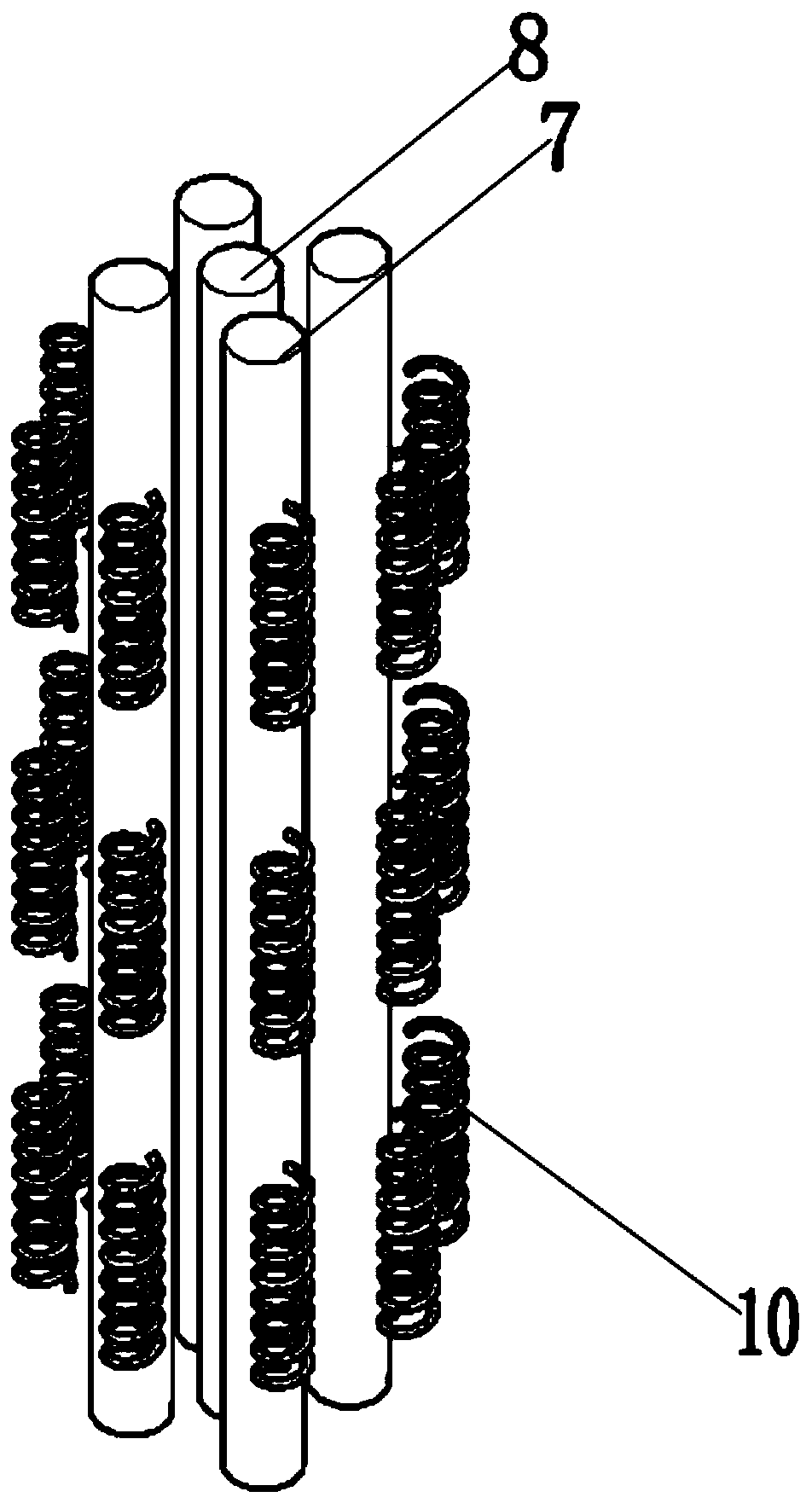

[0074] The interior of the filling layer 3 6 is provided with a special-shaped heat pipe 2 10;

[0075] Such as image 3 As shown, the special-shaped heat pipe 10 is a spiral micro-heat pipe, the number of which is multiple and intermittently arranged up and down, and each of the special-shaped heat pipes 9 is arranged parallel to the axial direction of the transmission line 7, and a plurality of special-shaped heat pipes 19 surrounds Arranged in the filling layer 3 6;

no. 3 example

[0077] Such as Figure 4 and Figure 5 As shown, the inside of the filling layer 3 6 is provided with a special-shaped heat pipe 3 11;

[0078] Such as Figure 6 As shown, the special-shaped heat pipe three 11 includes: arc heat pipe one 101, arc shrapnel one 102, through hole one 103, arc shrapnel two 104, arc heat pipe two 105, arc shrapnel three 106, arc shrapnel four 107, through hole two 108;

[0079] The upper part of the arc-shaped heat pipe 101 is connected with the lower part of the arc-shaped shrapnel 102;

[0080] The lower part of the first arc-shaped heat pipe 101 is connected to the upper part of the second arc-shaped shrapnel 104;

[0081] The upper part of the arc-shaped heat pipe two 105 is connected with the lower part of the arc-shaped shrapnel three 106;

[0082] The lower part of the arc-shaped heat pipe two 105 is connected with the upper part of the arc-shaped shrapnel four 107;

[0083] Described arc shrapnel one 102 is provided with through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com