Inclined hole laser cutting method and cutting device

A technology of laser cutting and inclined holes, which is applied in the field of plate processing, can solve problems such as deformation and uneven cooling of plates, and achieve the effect of increasing heat transfer coefficient, reducing recasting layer and heat-affected zone, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

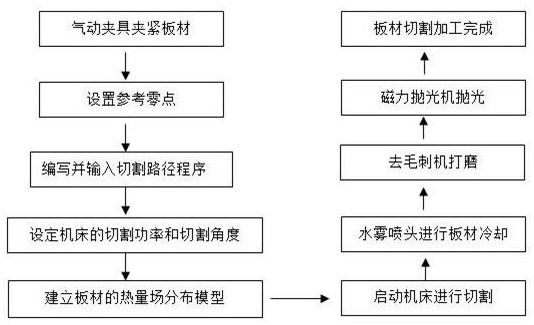

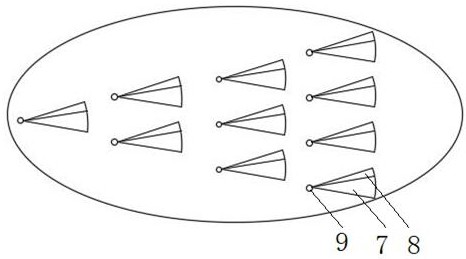

Method used

Image

Examples

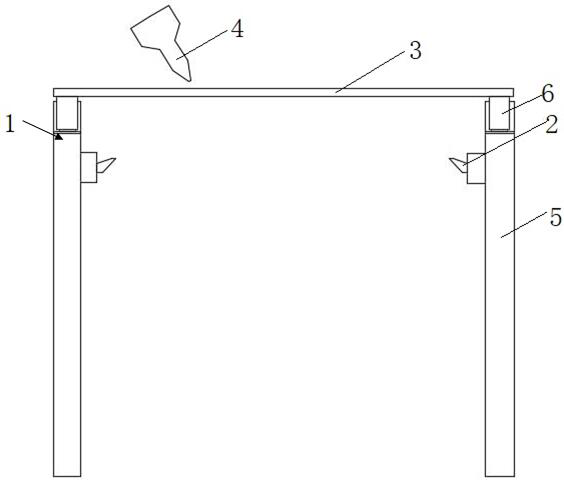

Embodiment 1

[0052] Taking 1.5mm stainless steel X6Cr17 as an example, the laser direction is 90° perpendicular to the plate. Place the stainless steel plate on the pneumatic fixture, tighten the pneumatic fixture, move the cutting head of the machine tool to the zero position, close the protective door of the machine tool, set the machine parameters, cutting power 3500W, cutting speed 20m / min, focus position -1.5mm, frequency 5000KHz, Gas pressure 1.8MPa. Run the cutting program, the machine tool runs according to the set program trajectory, and the program controls the laser on and off when cutting the path. The cutting direction is perpendicular to the sheet. There is no burr at the laser outlet of the cut sample, and the cutting edge is smooth.

Embodiment 2

[0054] Taking 1.5mm stainless steel X6Cr17 as an example, the laser direction is at an angle of 80° to the plate, that is, the cutting head is inclined at 10°. Place the stainless steel plate on the pneumatic fixture, tighten the pneumatic fixture, move the cutting head of the machine tool to the zero position, close the protective door of the machine tool, set the machine parameters, cutting power 3500W, cutting speed 15m / min, focus position -1.5mm, frequency 5000KHz, Gas pressure 1.8MPa. Run the cutting program, the machine tool runs according to the set program trajectory, and the program controls the laser on and off when cutting the path. The cutting direction is at an angle of 10° to the plate. There is no burr at the laser outlet of the cut sample, and the cutting edge is smooth.

Embodiment 3

[0056] Taking 1.5mm stainless steel X6Cr17 as an example, the laser direction is at an angle of 70° to the plate, that is, the cutting head is inclined at 20°. Place the stainless steel plate on the pneumatic fixture, tighten the pneumatic fixture, move the cutting head of the machine tool to the zero position, close the protective door of the machine tool, set the machine parameters, cutting power 3500W, cutting speed 10m / min, focus position -1.5mm, frequency 5000KHz, Gas pressure 1.8MPa. Run the cutting program, the machine tool runs according to the set program trajectory, and the program controls the laser on and off when cutting the path. The angle between the cutting direction and the plate is 20°. There is no burr at the laser outlet of the cut sample, and the cutting edge is smooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com