Novel aluminum-plastic composite belt longitudinal wrapping and releasing tension constant device

A technology of aluminum-plastic composite tape and vertical wrapping, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc. It can solve problems such as warped angles and broken tapes, and achieve the effect of eliminating broken tapes and improving the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution adopted by the present invention will be further described below in combination with schematic diagrams.

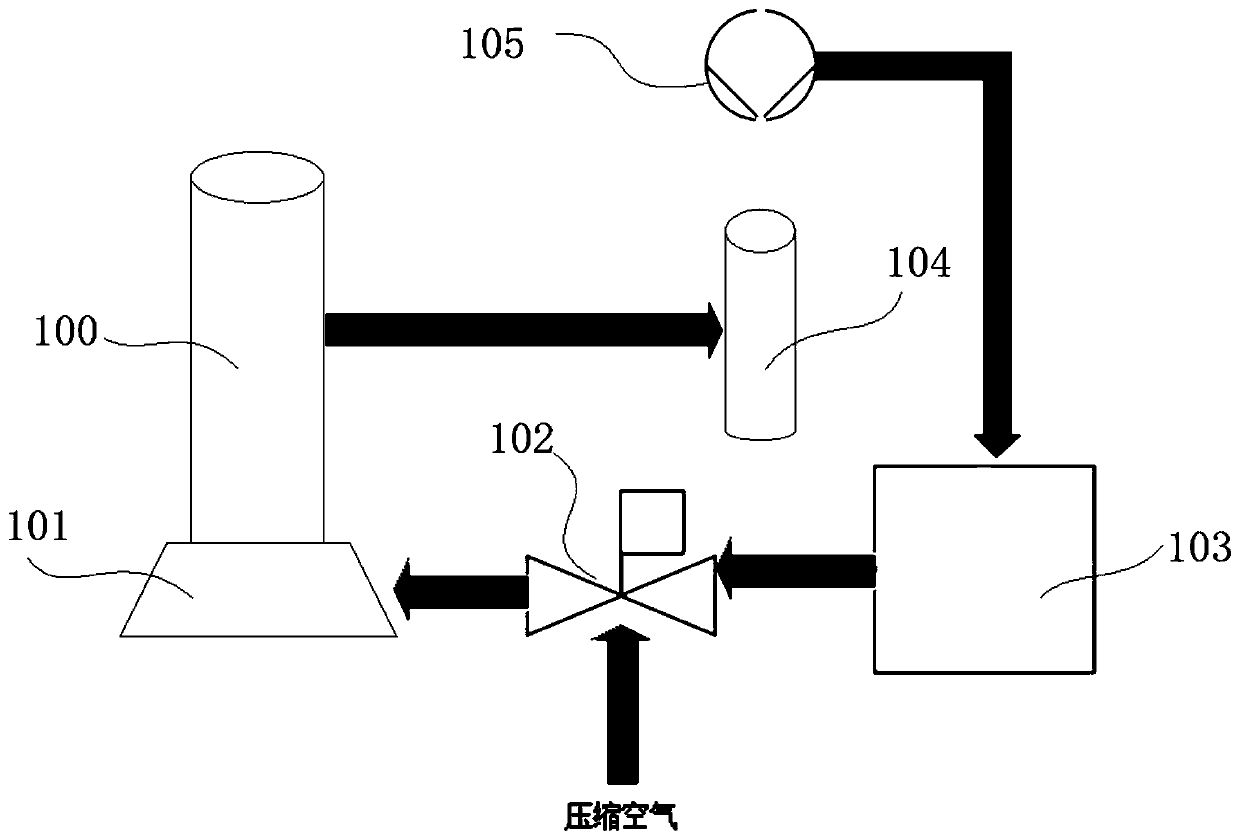

[0021] Such as figure 2 , a new type of constant tension device for longitudinal wrapping of aluminum-plastic composite tape, which includes a tape release frame 100, a pneumatic brake 101, a straightening roller assembly 104, and a tension sensor 105.

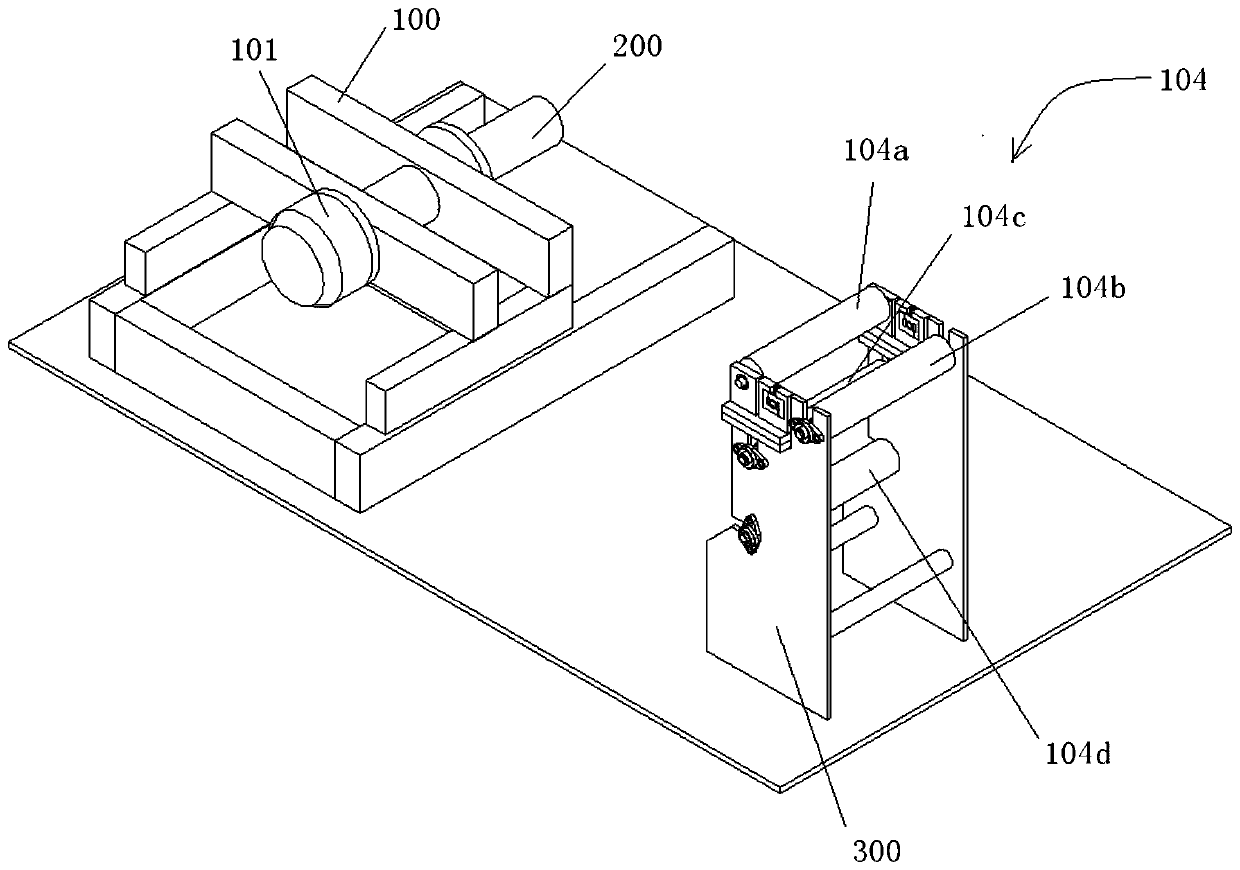

[0022] see image 3 , the tape rack 100 installs the aluminum-plastic composite tape roll through the release shaft 200 of the aluminum-plastic composite tape roll, image 3 Aluminum-plastic composite tape volume release shaft 200 is not installed with aluminum-plastic composite tape volume. The end of the tape roll protrudes from the bearing seat so as to install the corresponding brake assembly. A pneumatic brake 101 is installed at the release shaft of the aluminum-plastic composite tape of the tape rack, and the pneumatic brake 101 can brake the release shaft of the aluminum-plastic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com