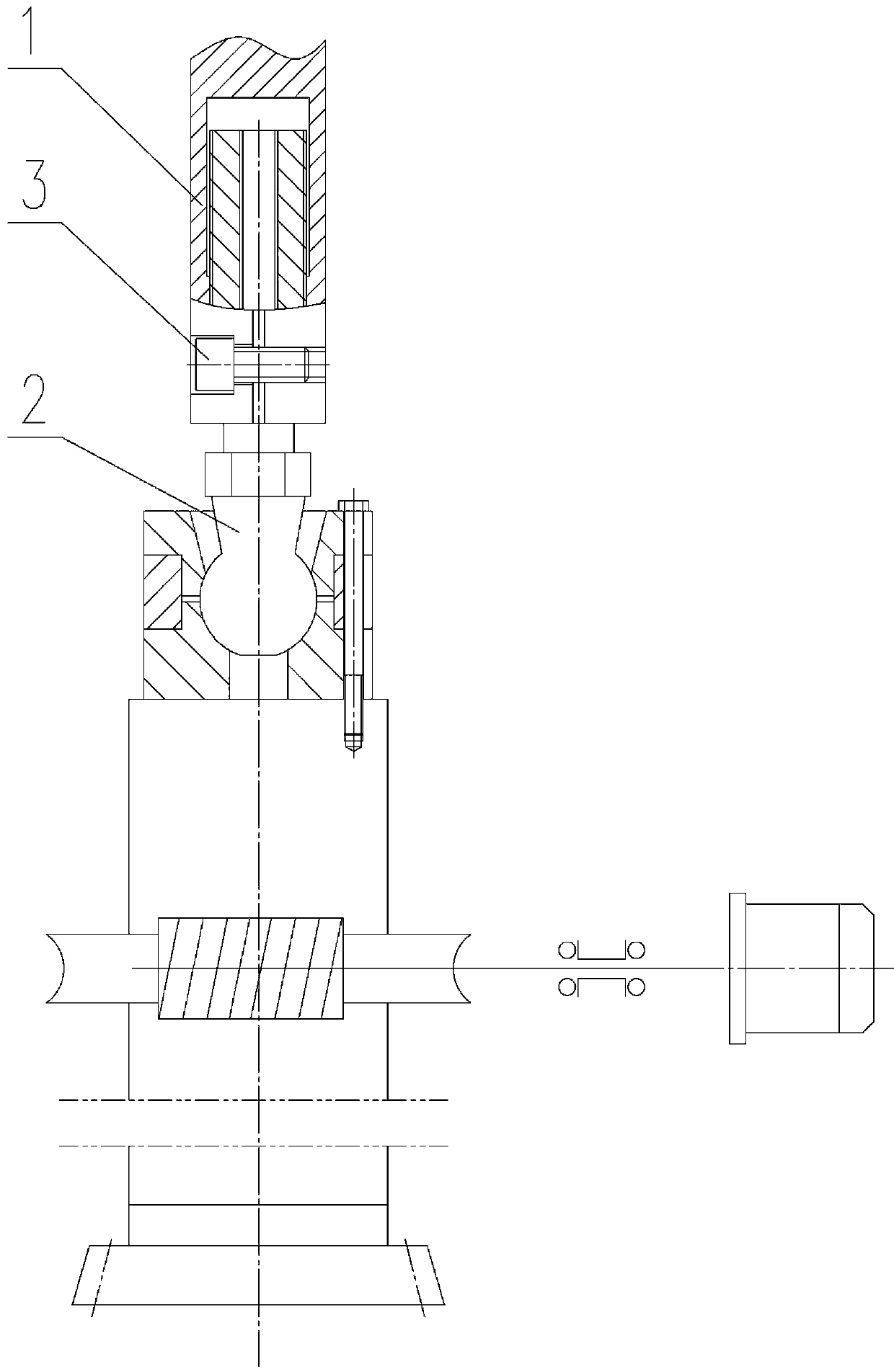

Automatic adjustment structure and method of cutter position of gear shaper

A technology of automatic adjustment and gear shaper, applied in the direction of gear cutting machine, gear teeth, mechanical equipment, etc., can solve the problems of increasing worker safety risk, reducing production efficiency, inconvenient operation, etc., to eliminate the risk of tool hitting the workpiece and reduce labor. Strength, easy to manufacture and assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

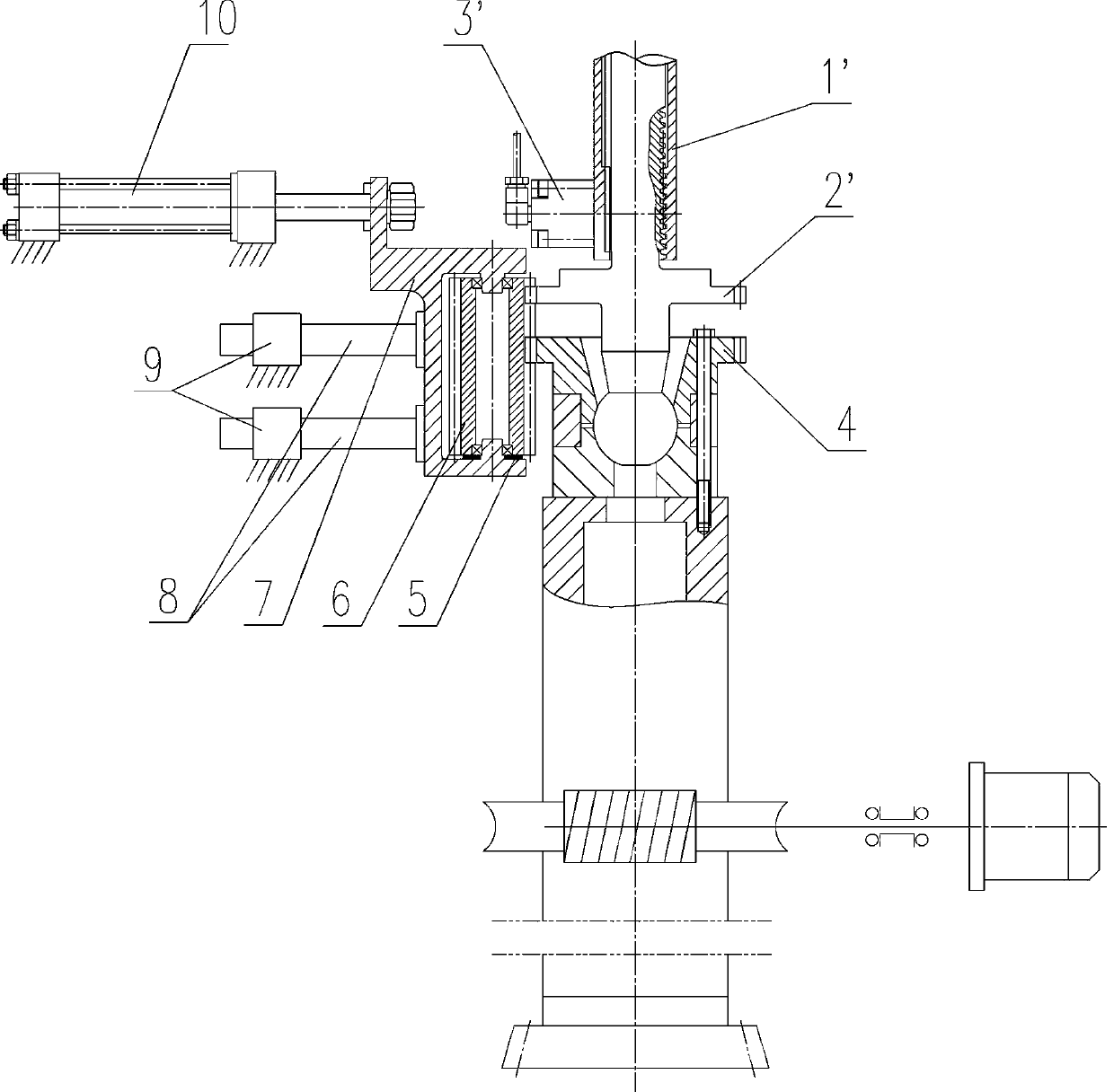

Embodiment 2

[0031] The method of adjusting the tool position by the automatic adjustment structure of the tool position of the gear shaper. When the tool position is adjusted, the swing rod stops to ensure that the ball tie rod 2' is in a vertical state, the thread locking cylinder 3' is filled with oil, and the locking is released. The thread of the ball tie rod; the oil cylinder 10 pushes the gear base 7, and pushes the transition gear 6 to move through the gear base 7, so that the transition gear 6 meshes with the first gear of the ball tie rod 2' and the second gear 4 on the gear cover at the same time; The tooth-splitting motor of the cutter drives the cutter shaft to rotate, the cutter shaft synchronously drives the second gear 4 to rotate, and then drives the transition gear 6 synchronously through the second gear 4, drives the ball tie rod 2' to rotate through the transition gear 6, and then passes the swing rod 1 ' and the thread on the ball tie rod 2' drive the ball tie rod 2' to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com