Feeding-discharging cantilever for laser cutting machine

A laser cutting machine and cantilever technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as safety production accidents, reduce production efficiency, and affect production progress, so as to isolate potential safety hazards, improve production efficiency, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

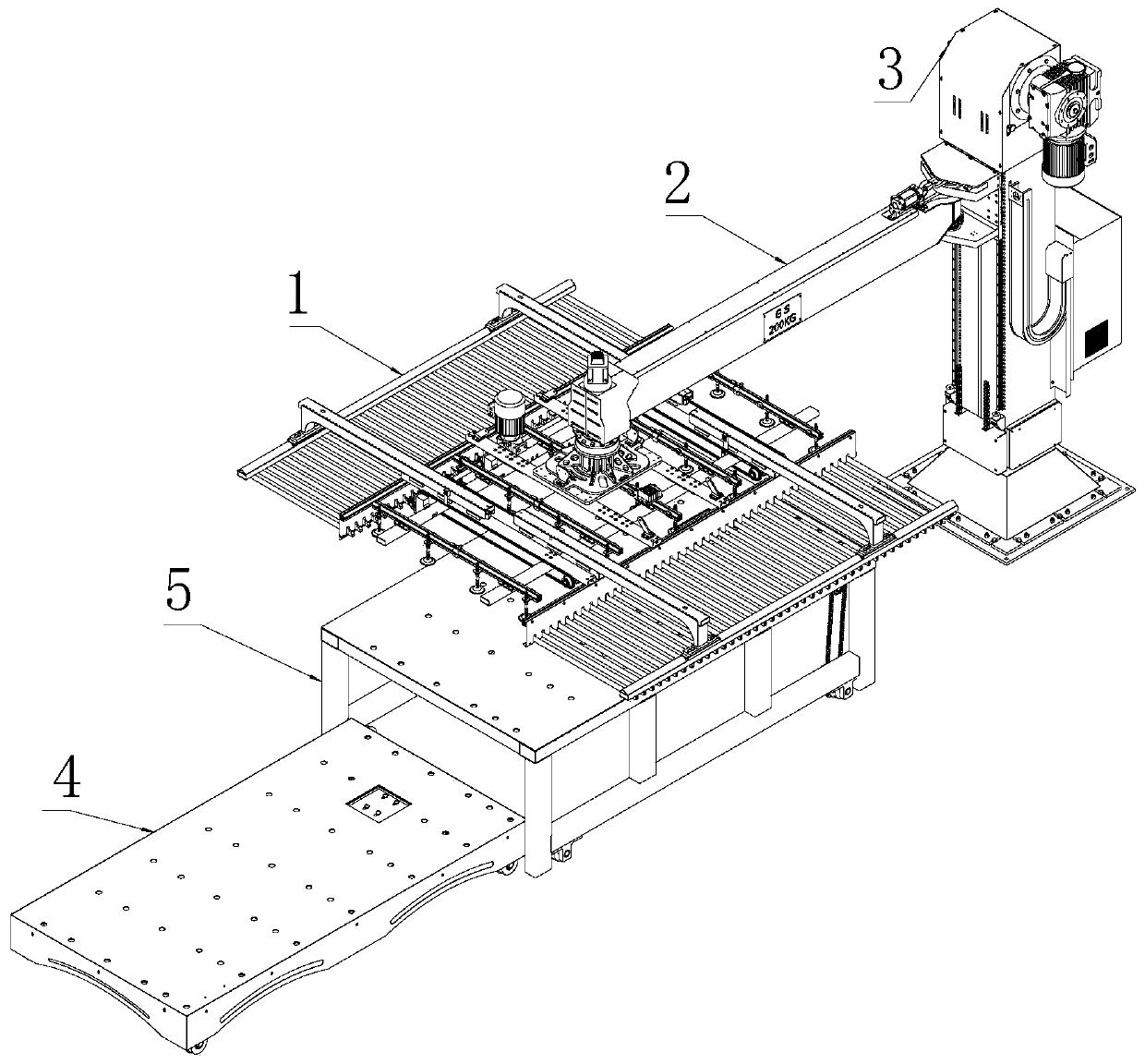

[0035] Please see attached figure 1 , a loading and unloading cantilever for a laser cutting machine, comprising a suction cup insert 1, a cantilever 2, a column 3, a raw material car 4 and a finished car 5.

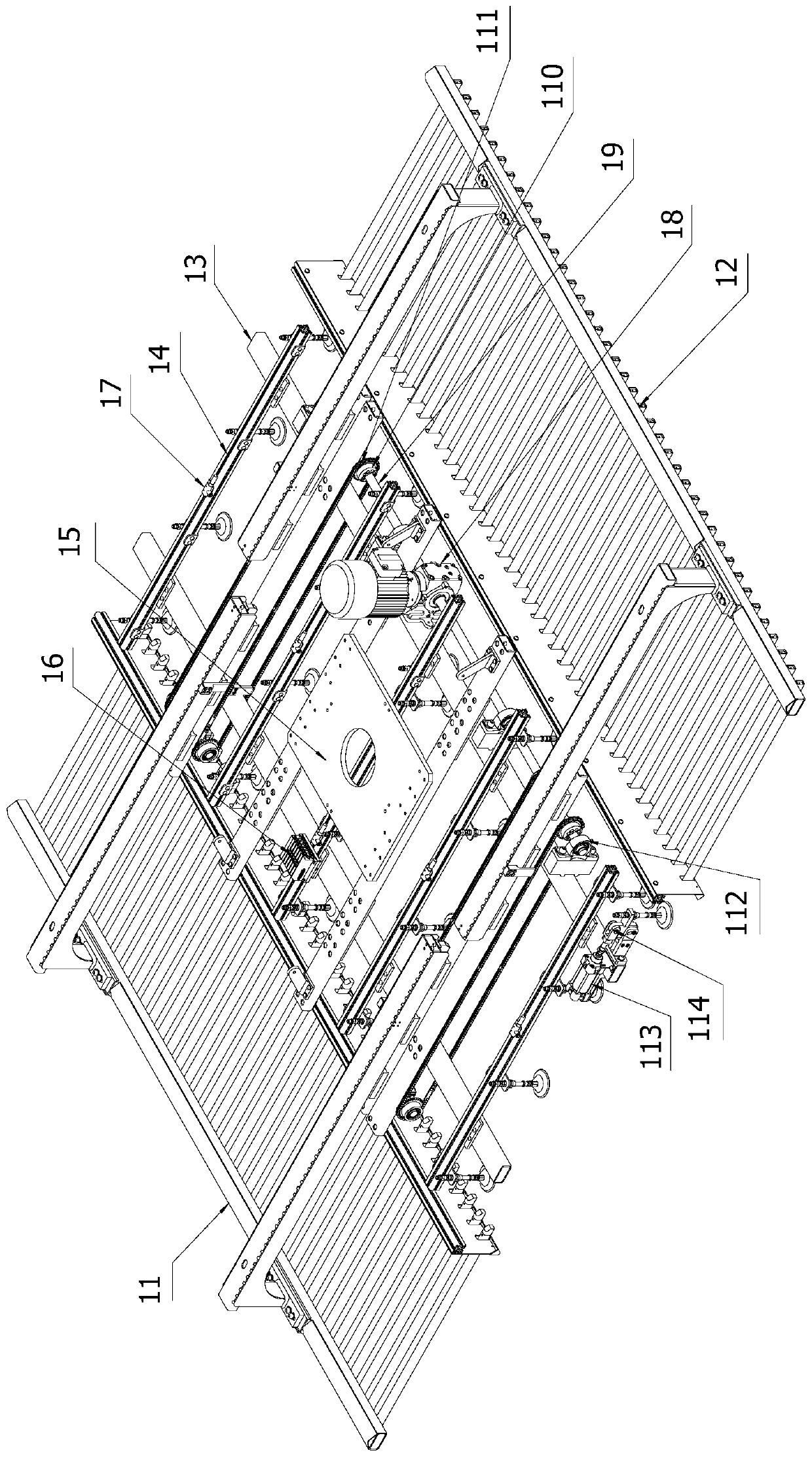

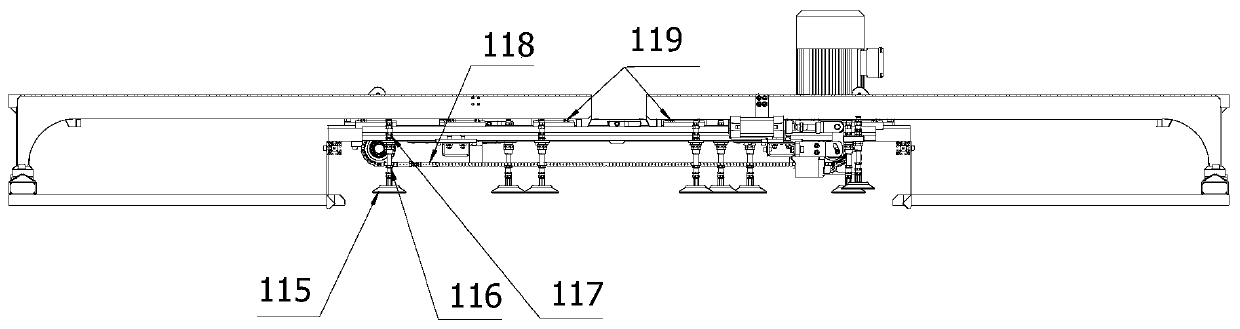

[0036] Please see attached figure 2 And attached image 3 , the suction cup socket 1 includes a suction cup socket main body 13, a suction cup mounting aluminum profile 14, a suction cup mounting motherboard 15, a pneumatic suction cup 115, a separation plate component, and a pneumatic control component; the suction cup mounting motherboard 15 is installed on the suction cup socket In the center of the frame main body 13, several suction cup mounting aluminum profiles 14 are arranged at intervals on the suction cup inserting frame main body 13, and several pneumatic suction cups 115 are installed at intervals on the bottom of each suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com