Full-automatic panel processing all-in-one machine and using method thereof

A sheet metal processing, fully automatic technology, applied in wood processing appliances, manufacturing tools, unloading equipment and other directions, can solve the problem of automatic and stable feeding, etc., to improve feeding efficiency, improve production efficiency, and reduce manual intervention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

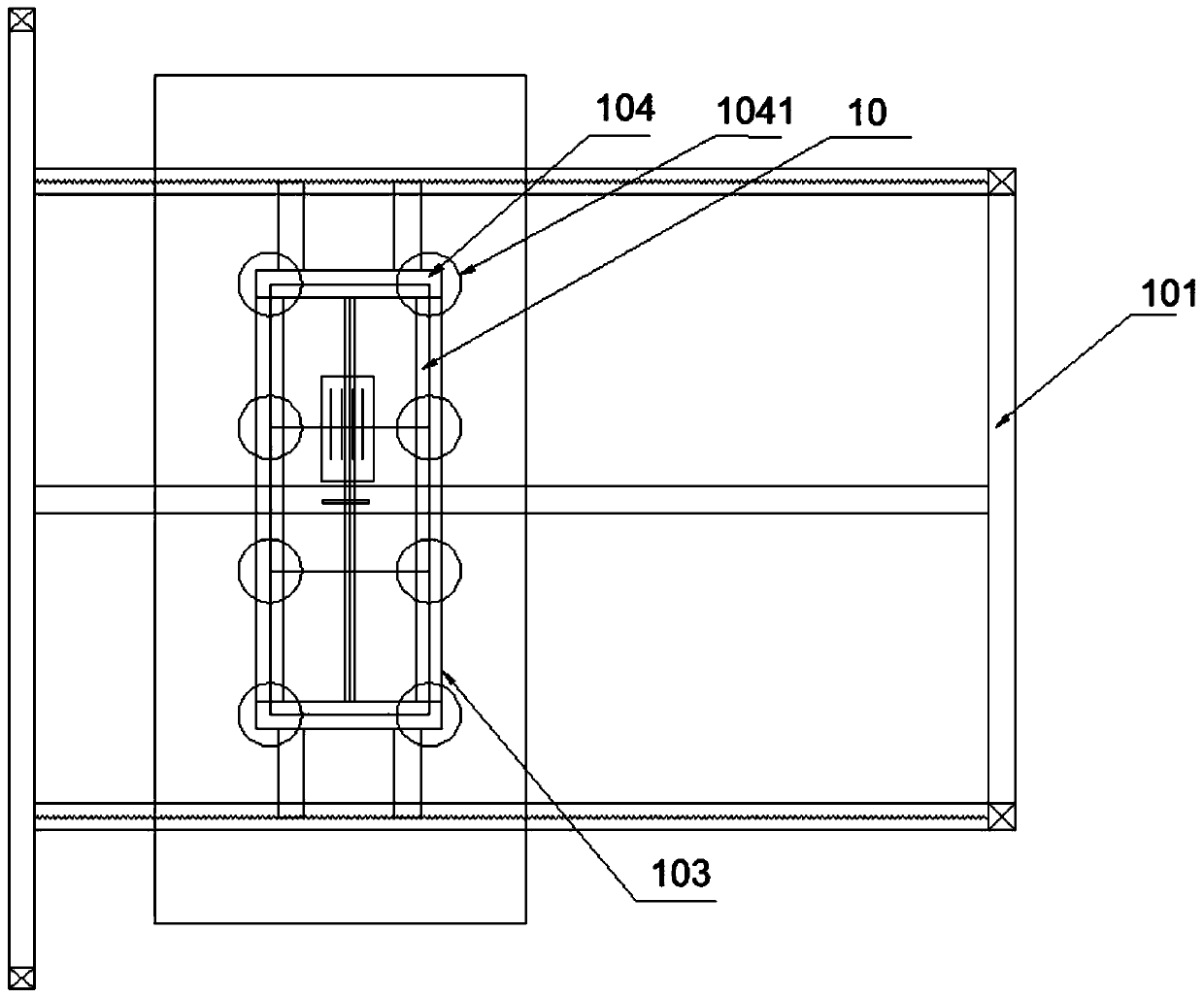

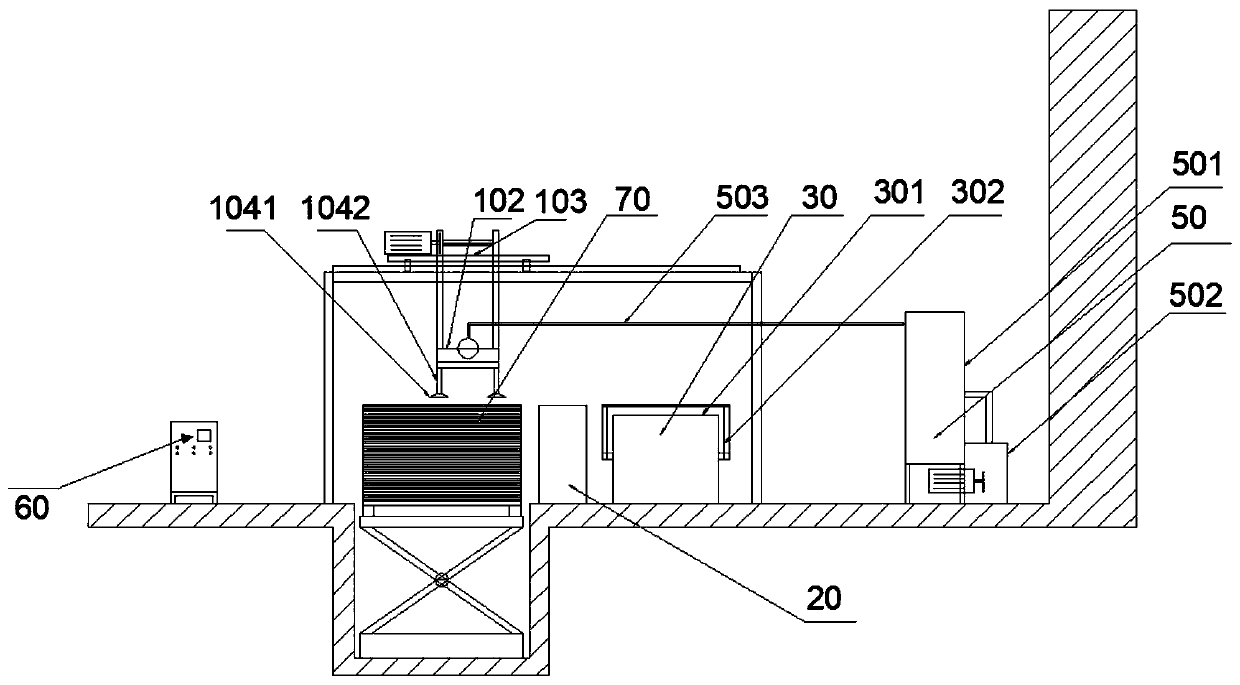

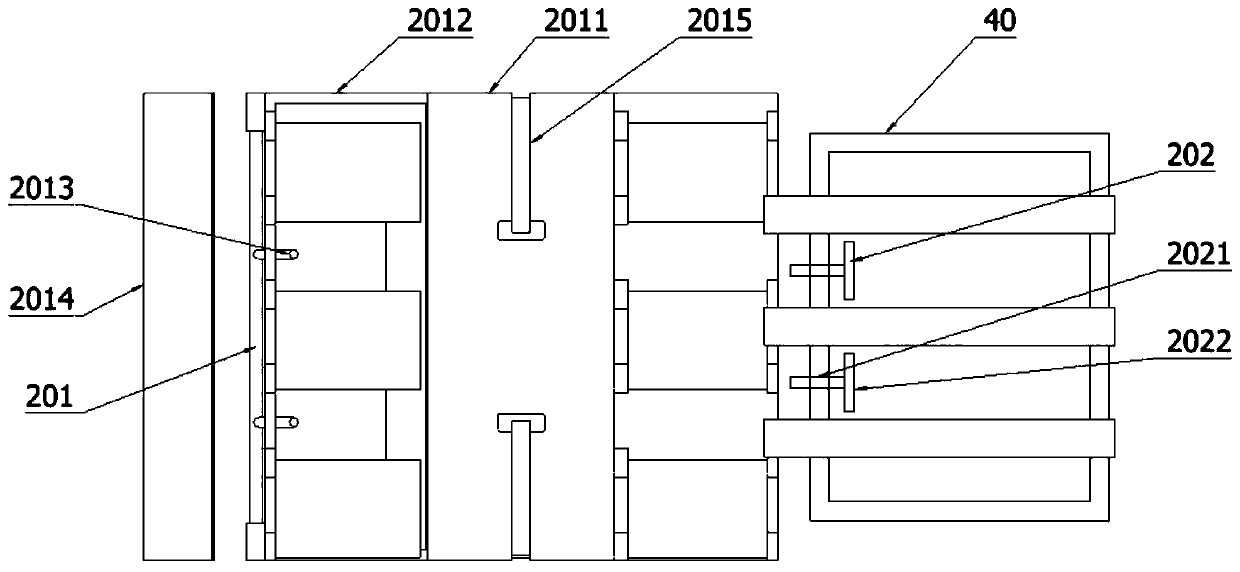

[0044] Such as figure 1 , 2 As shown in , 3 and 4, this embodiment discloses a fully automatic plate processing integrated machine, including: a feeding part 10, a feeding part 20, a cutting part 30, the feeding part 10 is arranged on a plane, and the feeding part 10 For grabbing the sheet material 70, the feeding part 10 is provided with an accommodation space inside, the feeding part 20 is arranged on a plane, the feeding part 20 is connected with the feeding part 10, and the feeding part 20 is partially arranged in the accommodation space, and the feeding part 20 is arranged in the receiving space. The feeding part 20 is arranged parallel to the plane, and moves in parallel when the feeding part 20 is displaced. The feeding part 20 is used to receive the plate 70 of the feeding part 10, and the cutting part 30 is arranged on the outer periphery of the feeding part 10. The cutting part 30 and The feeding part 20 is connected, and the cutting part 30 is detachably connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com